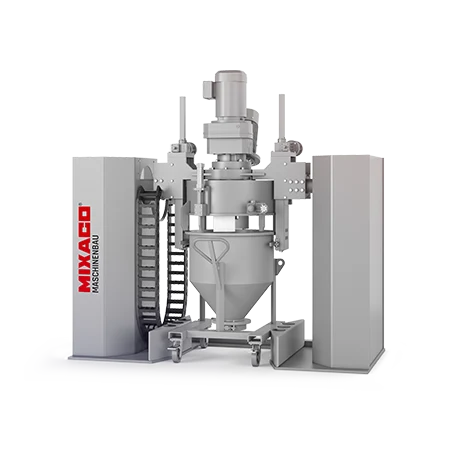

Batch Mixer

Mix batches from 5 to 10,000 liters. Batch mixer for all raw materials.

MIXACO Batch Mixer – also for your raw materials.

Advantages of our batch mixers. Mix dry & wet bulk materials & raw materials.

MIXACO batch mixers are available as laboratory mixers with 5 up to 12 liters volume for small batches and product development. For batches up to 200 liters, our bag mixers or drum mixers are very well suited. We also have mixers for all larger batches up to a batch size of 10,000 liters.

Our batch mixers are also suitable for very sensitive raw materials, which are mixed gently, quickly and homogeneously. Mix even delicate components without wear, breakage, dust formation or static electricity.

MIXACO batch mixers can mix without temperature input – heated or cooled mixing is also possible.

- Excellent homogeneity & perfect mixing quality

- Preservation of particle integrity

- Perfect mixing from as little as 2 minutes mixing time

- Consistently reproducible mixing quality of each batch

- Batch traceability

- Extremely fast batch changes due to container principle

- Low energy consumption

- Vertical or horizontal batch mixers

- Low-cost, use-dependent maintenance

- Special surfaces for food (coatings)

- Dust-free discharge stations

- Double jacket designs for temperature control

- Reduction of process time by mixing in less time than with commercially available mixing systems

- Multiple process steps in one batch mixer: mixing, moistening, flavoring, coating, melting, etc.

- Batch mixers can be integrated into existing production processes or used as stand-alone units

- High throughputs, rapid emptying and fast recipe changes

- Variable filling level up to 80%

- No dead spaces or cavities in the interior of the mixer

- No product contamination due to closed mixing chamber

- Sizes of our mixers from 5 to 10,000 liters

- High mixing quality even with difficult components – for end products of consistent quality

- Extremely gentle mixing – if necessary also without heating – allows homogenization of the most sensitive raw materials

- Gentle mixing of fragile powders (for example filigree effect pigments) without breakage or dust formation

- Batch mixers convince by simple and very safe handling

- Minimal cleaning effort for fast recipe changes: mixing elements and mixing tools easily accessible and demountable

- Robust & low-maintenance machine technology “Made in Germany” guarantees high availability

- Batch mixers in ATEX executions

- Time-saving, hygienic design

- Mixing parameters individually adjustable

- Joint product development and mixing optimization in our test centers

- Innovative monitoring of the batch mixers via the MIXACO Control Center (cloud monitoring)

Mixer Quotation Configurator: Just 2 minutes to the perfect mixer for your raw materials.

Simply tell us your requirements and we will recommend you the optimum mixer for your raw materials and applications. Use our configurator.

With your details on quantities, mixtures, temperatures, additional functions and other information, we will prepare a customized quotation for you.

Batch mixers for countless raw materials and industries. For numerous batch sizes.

Our batch mixers blend dusts, powders, granules, flakes and countless particles and components from a wide variety of raw materials. Mix perfect masterbatches and almost all dry and wet raw materials from a wide range of industries:

- Food & nutritional supplements

- Pet food for pets, livestock and exotics

- Detergents & cleaning products

- Fertilizers, Insecticides, Pesticides, Herbicides

- Paints, powder coatings, pigments & toners

- Building materials such as cement, plaster, silicates and mortar

- Ceramic powders

- Battery powder

- Metal powders and granules

- Plastics, polymers, rubber

- Powder for cosmetic products

- Powders for fire extinguishers and fireretardant products

- And many more

Mixing Techniques. Batch mixer for various mixing applications.

Batch mixers from MIXACO are suitable for a wide variety of mixing processes and applications in the processing of countless raw materials:

- Homogenization of bulk materials

- Mixing of irregular components

- Agglomeration

- Masterbatches

- Intensive deagglomeration

- Gentle homogenization

- Wetting of particles

- Digestion

- Improvement of product quality

- Change of functions and properties

- and much more

Individual Options. Perfectly matched to the processing of your raw materials.

MIXACO batch mixers are available in various shapes and sizes and are suitable for countless mixing techniques and processing methods. Batch mixers without a base plate are possible.

Via various options, our batch mixers are perfectly adapted to the processing of your raw materials. Your raw materials and your applications decide. We also develop completely individual batch mixers specifically for your requirements.

- Dedusting

- Temperature measurement

- Integrated weighing

- Aeration and feeding during mixing process

- Dosing / spraying / injection of liquids and gases during the mixing process

- Mixing head cooling

- Sampling

- Explosion-proof ATEX versions

- Data recording and evaluation

- Cloud monitoring (MIXACO Control Center) & remote maintenance

- Hygienic design

- Cleaning wet or dry

- Batch mixer design according to GMP, WIP, CIP

- Batch mixer including cooling, heating, drying

- Water cooled motor

- Batch mixing under vacuum, coating and drying

- Batch mixers with individual mixing tool geometries

- Wear resistant designs against abrasion, corrosion and adhesion

- Dust-resistant machine components

- Individual sealing variants

- Hydraulic lids and discharge flaps

- And much more

As the inventor of the container mixer, we at MIXACO are committed to innovation in industrial mixing technology.

FAQ. Batch Mixer Knowledge.

A batch mixer mixes two or more raw materials in whole batches, as the name suggests. It is a so-called discontinuous mixer. In contrast to this are continuous mixers, in which substances are continuously fed in to ensure a continuous production flow.

Batch mixers can be completely stationary or mobile, likewise the mixing containers can be fixed or mobile. Batch mixers with mobile mixing containers are referred to as container mixers. By changing the entire mixing container, batch changes are extremely fast and the production flow is only minimally interrupted.

MIXACO invented the container mixer, which reduced the batch times with charging, mixing and discharging to only 8 minutes.

Batch mixers are available as vertical or horizontal batch mixers and in many sizes for different sized batches.

A laboratory batch mixer blends batches of up to about 12 liters – ideal for small quantities, recipe testing or product development.

The next larger batch mixer is a bag mixer or drum mixer, which can mix batches of up to 200 liters at a time.

Batch mixers are available in many other sizes for individual requirements, raw materials and throughput quantities. Up to 4,500 kg or more can be mixed in one batch. High capacities can be realized with batch mixers.

One of the advantages of batch mixers is that the combination of ingredients can be precisely controlled, guaranteeing optimum control over the quality of the final product.

Batch mixers can have different designs. The typical mixing vessel of a horizontal batch mixer has the shape of a cylinder. A vertical batch mixer is usually a v-shaped cone mixer. A variant is the double cone mixer, the mixing vessel of which narrows conically at both ends.

Batch mixers are used in many industries, for example for food, animal feed, cosmetics, tablets, plastics, paints, powder coatings, minerals, metals, rubber, PVC, detergents, cement, plaster and many more.

A batch mixer mixes dry and wet powders, granules, flakes and dusts. A good batch mixer also mixes delicate, fragile and non-uniform particles without degradation.

Due to the large number of different raw materials, it should be possible to configure a batch mixer individually for each material and recipe.

Various mixing parameters play a role in choosing the right batch mixer:

- Type of raw materials / mixed materials

- Bulk density

- Desired batch size

- Desired throughput per hour

- Targeted batch times

- Use of different sized mixing vessels / containers

- Quality of end products

- Input of heat

- Mixing intensity

- Size, shape and moisture content of the powder particles to be mixed

- Production facilities

- Integration into production processes

- Mixing accuracy

- Approved construction materials

- Energy consumption

- etc.

The desired mixing processes also influence the choice of the right batch mixer:

- Homogenize

- Agglomerate

- Deagglomeration

- Dispersing

- Moistening

- Digestion

- Melting

- Coating

- Bonding

- Mix under vacuum, moisten, dry

- etc.

Also consider factors of cleaning and hygiene when choosing a batch mixer:

- Prevent contamination

- Food safe surfaces

- Wear resistant surfaces

- Cleaning of the batch mixer between batches

- Fast drying possible

- Cleaning according to food hygiene

- etc.

Service & support for our batch mixers. You can rely on us and our experienced technicians.

More than mixers. Holistic customer care for over 55 years.

Test mixer free of charge and without obligation

Test our mixers in our test center – with your own raw materials, of course.

Learn More

Mix & Process Consulting

Have your mixing process checked by our mixing professionals – free of charge & no obligation.

Learn More

The MIXACO Technical Center

In our test centers we can optimize all parameters for your compound.

Learn MoreFor further information please do not hesitate to contact us.

Guido Brand

Sales & Marketing

MIXACO

Dr. Herfeld GmbH & Co. KG

Niederheide 2

58809 Neuenrade

Germany

+49 (0)2392 9644-210

sales@mixaco.de