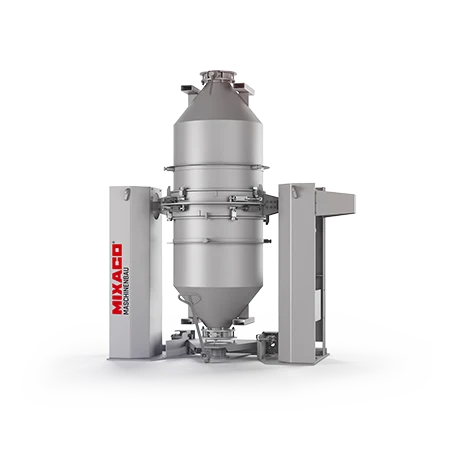

Cone Mixer

Cone Mixer with Container Change. Faster and very flexible.

Advantages of the MIXACO Cone Mixer

MIXACO Cone Mixer – also for your solid raw materials.

Advantages of our conical mixers. Perfect mixing qualities due to mixing upside down.

Convince yourself of the advantages of our conical mixers in the variant as container mixers with exchangeable mixing cones:

- 100 % perfect mixing without dead spaces due to mixing position upside down

- Acceleration of production processes due to short mixing times starting from 2 minutes

- Consistently reproducible mixing quality – even with different filling levels

- Batch tracing

- Extremely fast batch changes due to container principle

- Low energy consumption

- Low-cost, use-dependent maintenance

- Special surfaces for food products (ViwateQ coating)

- Low-dust discharge stations

- Temperature-neutral mixing of sensitive goods

- Multiple process steps in one conical mixer: mixing, moistening, flavoring, coating, melting, etc.

- High throughputs, rapid discharge, fast recipe changeover

- Variable filling level up to 80%

- No product contamination due to closed mixing chamber

- Batch sizes up to 2,000 liters

- High mixing quality even with difficult components – for end products of consistent quality

- Gentle mixing of fragile powders (e.g. filigree effect pigments) without breakage

- Reduction of rejects (e.g. pigment savings when mixing paints, powder coatings, etc.)

- Easy and very safe handling of the mixers

- Minimal cleaning effort for fast recipe changes: mixing elements and mixing tools easily accessible and demountable

- Robust and low-maintenance machine technology “Made in Germany” guarantees high availability

- Cone mixers with ATEX execution

- Time-saving, hygienic design

- Mixing parameters individually adjustable

- Mixer test and mixing optimization in our test centers

- Innovative process control of the conical mixers via the MIXACO Control Center (cloud monitoring)

- Also available as post blender

- Less susceptible to faults and lower undermanagement costs compared to conical screw mixers

Mixer Quotation Configurator: Just 2 minutes to the perfect mixer for your raw materials.

Simply tell us your requirements and we will recommend you the optimum mixer for your raw materials and applications. Use our configurator.

With your details on quantities, mixtures, temperatures, additional functions and other information, we will prepare a customized quotation for you.

Cone mixers for countless raw materials and industries. In all batch sizes.

Our conical mixers are used in virtually all industries. They mix all dry or moist mixes – also in different particle sizes, bulk densities and flow properties.

For example, spice mixtures for the food industry or masterbatches for paint production can be homogenized. Our conical mixers perform any individual mixing task and can also function as dryers, reactors or evaporators in the heating mixer variant.

Benefit from the superior mixing process of our conical mixers also for your raw materials and products:

- Food mixing & food supplementation

- Pet food for pets, livestock and exotics

- Detergents & cleaning agents

- Fertilizers, insecticides, pesticides, herbicides

- Paints, powder coatings, pigments & toners

- Building materials such as cement, concrete, plaster, silicates and mortar

- Ceramic powders

- Battery powders, metal powders and granules

- PVC, plastics, polymers, rubber

- Countless powders for cosmetics, pharmaceuticals, chemicals

- and many more

MIXACO conical mixers process raw materials of widely varying consistencies:

- Granular consistency

- Powder

- Fine powder / dust

- Granules

- Flakes

- Pellets

- Flakes

- And many more

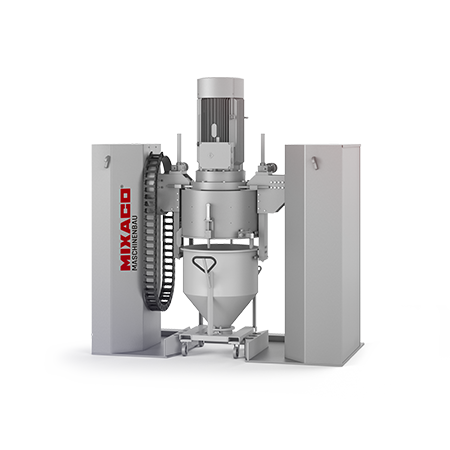

Mixing Processes. Cone mixer for various mixing processes.

MIXACO conical mixers are suitable for a wide variety of mixing processes and applications in the processing of countless raw materials:

- Homogenization of bulk materials

- Mixing of irregular components

- Agglomeration

- Intensive deagglomeration

- Gentle homogenization

- Wetting of particles

- Disintegration

- Improvement of product quality

- Change of functions and properties

- and much more

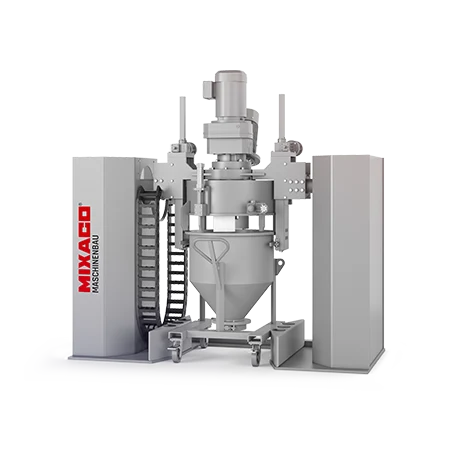

Options. Perfectly matched to the processing of your raw materials.

MIXACO cone mixers are available in various sizes, also as innovative double cone mixers. Our conical mixers are suitable for countless mixing processes and processing methods. Cone mixers without base plate and guide fork are possible – for simplified handling and improved hygiene.

Via various options, our conical mixers are perfectly adapted to the processing of your raw materials:

- Dust removal with replaceable filter bags

- Temperature measurement

- Integrated weighing

- Ventilation and feeding during the mixing process

- Dosing / spraying / injection of liquids and gases during the mixing process

- Mixing head cooling

- Sampling

- Explosion-proof ATEX execution

- Double jacket design for temperature control of the mixed material

- Data recording and evaluation

- Innovative MIXACO Control Center & remote maintenance

- Hygienic design

- Cleaning wet or dry

- Cone mixer design according to GMP, WIP, CIP

- Cooling, heating, drying

- Water cooled motors

- Water cooled tools

- Mixing, coating and drying under vacuum

- Individual mixing tool geometries

- Wear-resistant designs against abrasion, corrosion and adhesion

- Dust-resistant machine components

- Individual sealing variants

- Hydraulic lids and discharge flaps

- and much more

As the inventor of the container mixer, we at MIXACO are committed to innovation in industrial mixing technology.

FAQ. Cone Mixer Knowledge.

A conical mixer has – as the name suggests – a cone-shaped mixing vessel in which two or more components are mixed. In contrast, the design can also be a drum, cylinder, cube or tetrahedron due to the geometry of the mixing vessel.

Cone mixers are mostly batch mixers or discontinuous mixers in which batches of mix are processed and removed one after the other (in contrast to continuous mixers).

According to the type of force input, a conical mixer can have a movable mixing vessel or movable mixing tools – usually these are augers or paddles / paddles. Accordingly, there are different types of cone mixers:

Cone screw mixer

The classic conical mixer has a rotating spiral or screw through which the material to be mixed is conveyed upwards along the container wall. The material sinks down over the center and is fed back into the mixing process. This is known as the convective mixing effect.

Cone twin screw mixer

In the twin screw mixer, two symmetrically mounted screws convey the mix from the bottom to the top. Due to gravity, the mix flows downwards in the middle, where it is picked up again by the screws.

Unlike the moving mixing tools, however, a cone mixer can also transfer force to the mixture inside by moving the mixing vessel. This type of mixer is often referred to as a drum mixer. A classic drum mixer is the cement mixer on the construction site.

MIXACO cone mixers have both moving tools and a moving mixing container that is turned upside down for the mixing process. Although it is not a classic drum mixer, the combination of the moving mixing tools and the overhead mixing achieves better mixing results and is much easier to clean than in a conventional conical mixer with a fixed mixing chamber.

In addition, MIXACO conical mixers can be equipped not only with screws and paddles, but also with numerous other mixing tools, some of which are patented. Thus, a MIXACO conical mixer can be used more flexibly and individually than conventional conical mixers.

Especially in food production, smaller mixers with particularly short mixing cycles are in demand. Feeding, mixing process and discharge should be as fast as possible.

No other conventional conical mixer can be emptied as quickly as a MIXACO conical mixer, because the principle of exchangeable mixing vessels or containers means that the next batch can be mixed directly while the previous mix in the container is fed to the next production step. Process interruptions for emptying are virtually non-existent.

Service & Support for our Cone Mixers. You can rely on us and our experienced technicians.

More than mixers. Holistic customer care for over 55 years.

Test mixer free of charge and without obligation

Test our mixers in our test center – with your own raw materials, of course.

Learn More

Mix & Process Consulting

Have your mixing process checked by our mixing professionals – free of charge & no obligation.

Learn More

The MIXACO Technical Center

In our test centers we can optimize all parameters for your compound.

Learn MoreFor further information please do not hesitate to contact us.

Guido Brand

Sales & Marketing

MIXACO

Dr. Herfeld GmbH & Co. KG

Niederheide 2

58809 Neuenrade

Germany

+49 (0)2392 9644-210

sales@mixaco.de