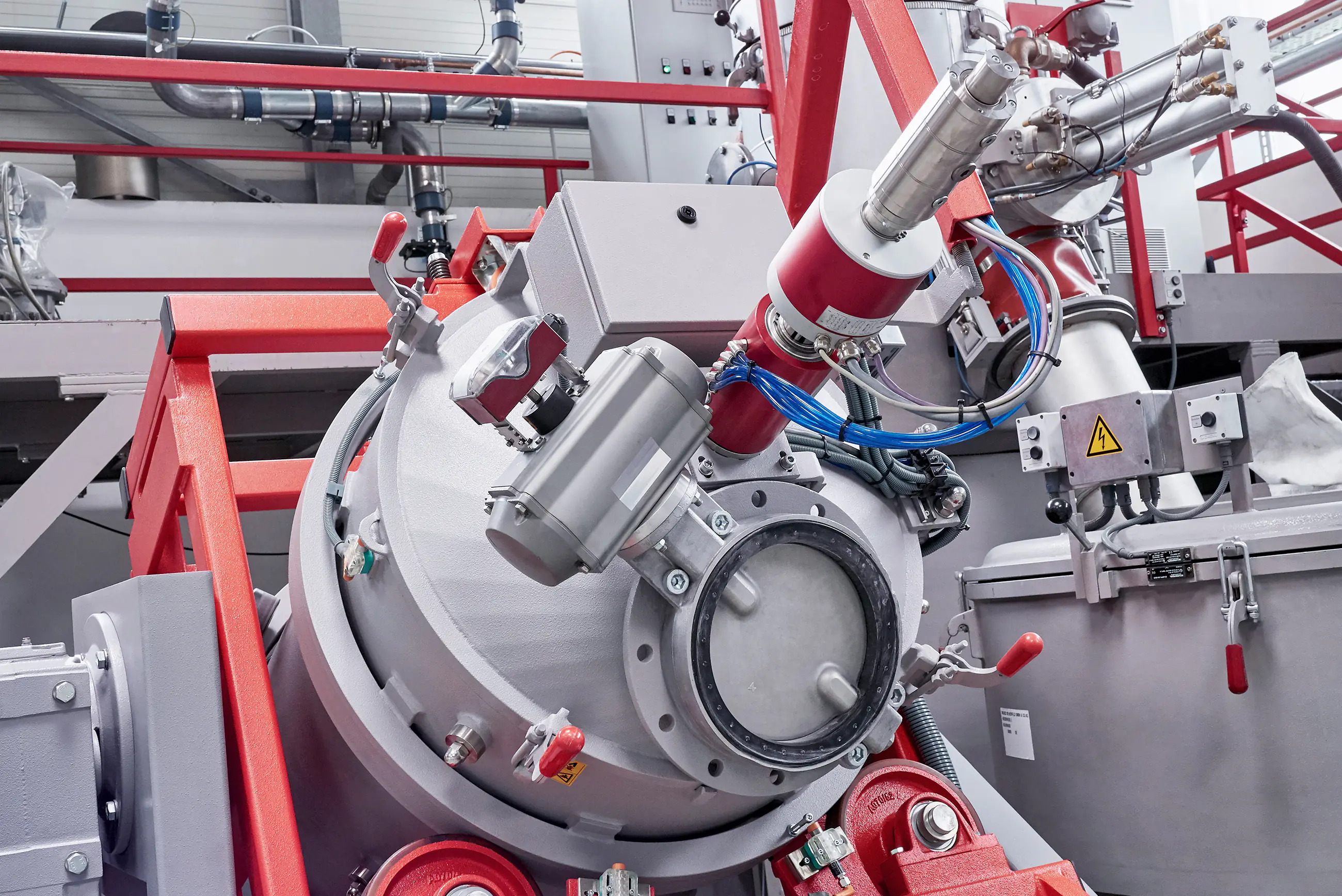

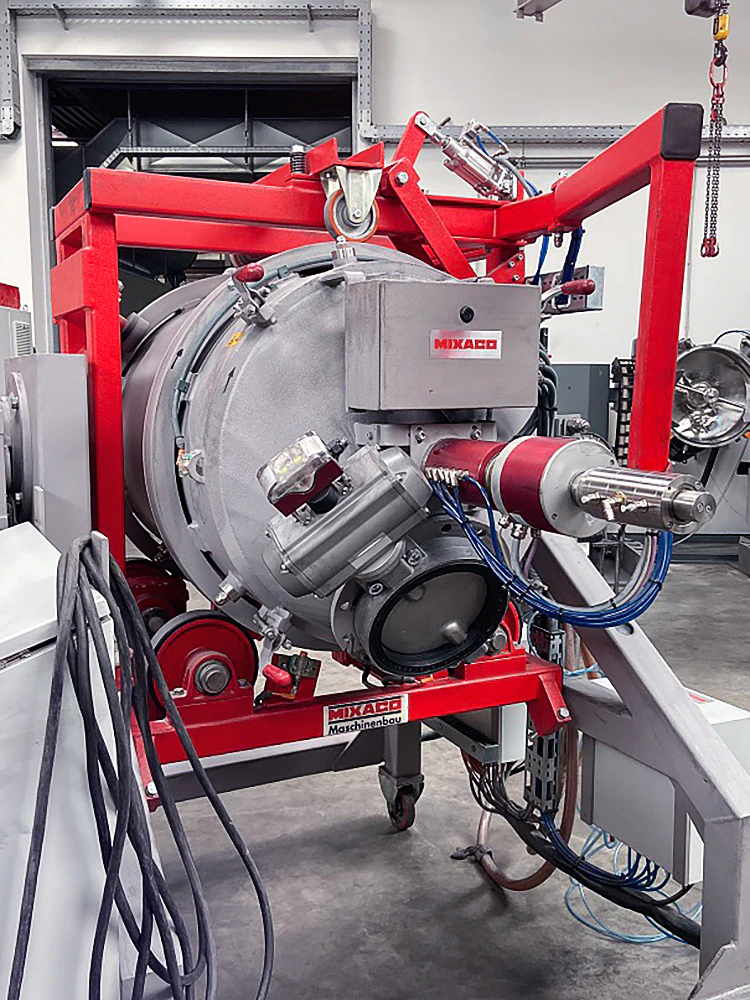

MIXACO Universal Mixer horizontal Revolution™

Advantages at a Glance. Gentle Mixing Revolutionized.

- Material-friendly, tool-free mixing system

- No heat input

- No abrasion of granules

- Best mixing quality for many applications

- Incredible batch sizes of up to 10,000 liters mixed

- Large cooling surface with low energy consumption

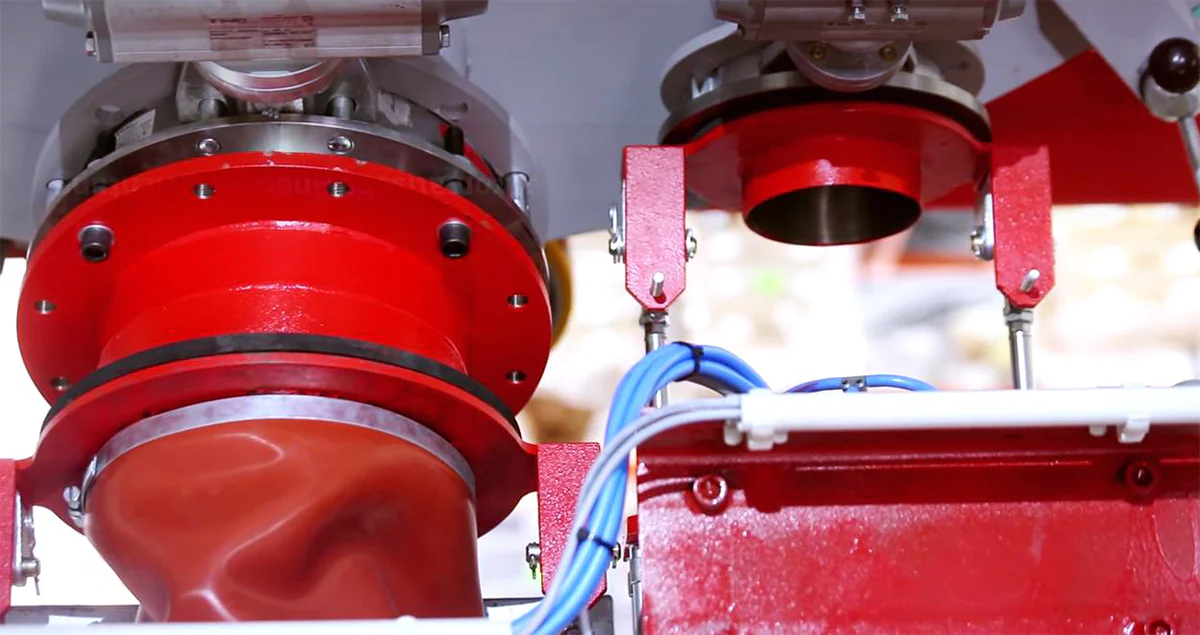

- 100% discharge

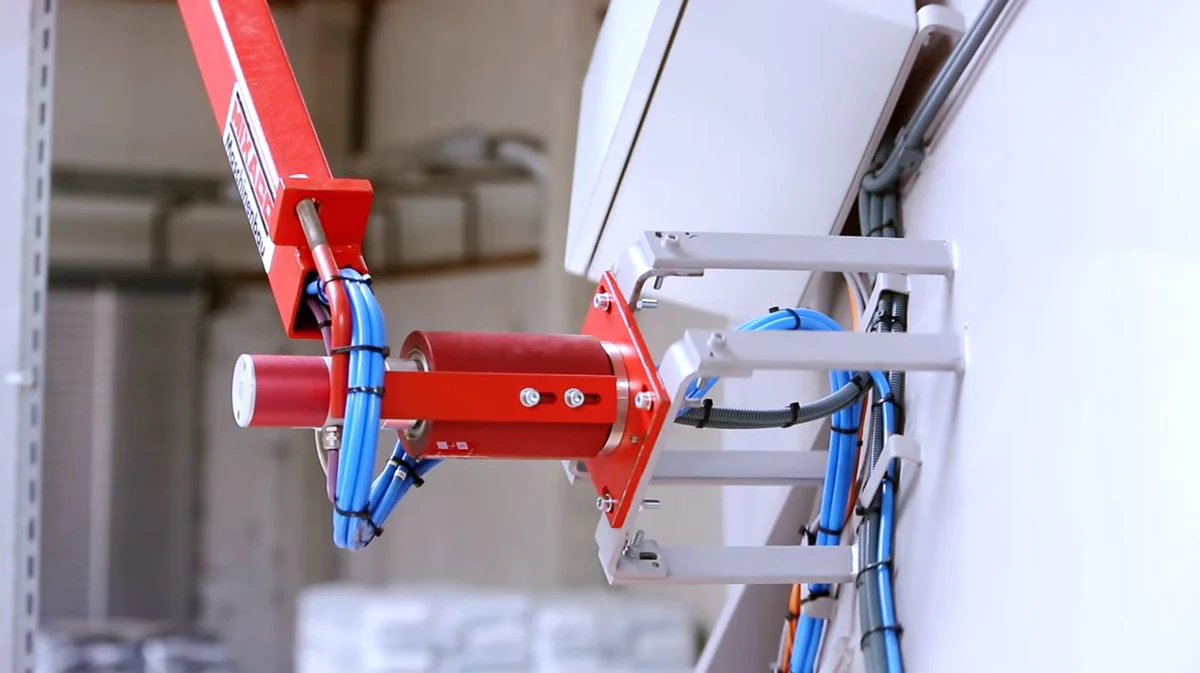

- Feeding coupling

- Inerting

- Fast cleaning due to sideways swiveling lid

- ATEX execution (up to zone 20 without inerting)

- Mixer is automatically brought into the filling and emptying position

- Additional options such as double jacket for temperature control, temperature measurement, injection, remote maintenance, cloud monitoring

Operating Principle. Mixing Without Active Mixing Tools.

The MIXACO Revolution™ is an innovative mixing system that works without active mixing tools. Without driven mixing tools in the mixing container, there is also no heat input into the mix.

The versatile universal mixer in horizontal execution has mixing segments built into the mixing vessel to provide uniquely gentle homogenization. A custom Revolution™ is the largest mixer we have built to date – it can mix batch sizes of up to 10,000 liters.

Mixer Control System. Safe, Efficient and Economical.

The control of the Universal Mixer Revolution™ is based on a Siemens S7 PLC and meets today’s requirements for safety, efficiency and economy. The development and programming of the control system from a single source ensures optimum integration of the mixer components. Alternatively, it is also possible to use Allen-Bradley components (incl. Panelview operating unit).

The control can also be executed according to UL / NEMA. In addition, the control can be equipped with an interface for data exchange to a higher-level control.

Siemens TP700

Up to 99 mixing programs, each with ten working steps, can be created in tabular form via the TP700 touch control panel. Data acquisition and storage of the measured values takes place.

Allen Bradley

Control to UL / NEMA standards with an Allen Bradley PLC and Panelview control panel is also possible.

Details. Innovative Functionalities.

Mixing Process. Homogenization of Large Batches.

The MIXACO Revolution™ is particularly suitable for extremely gentle mixing of large batches. The versatile horizontal universal mixer guarantees optimum mixing quality for numerous raw materials and applications.

- Gentle homogenization

- Homogenization of multiple material batches

- Dyeing

- Coating

- Wetting

- Gentle tempering of materials via water-carrying double jacket

- Mixing of sensitive materials

- and much more

The Innovative Mixer for Many Industries.

The MIXACO Revolution™ is the optimal mixer when particularly sensitive raw materials are to be gently homogenized.

Individual Options. From ATEX to Remote Maintenance.

The Revolution™ horizontal universal mixer offers maximum functionality through additional expansion options. Additional adaptations can be developed in cooperation with our engineers according to your individual requirements. We will be happy to advise you on the possibilities.

- Docking device for dust-free charging and discharging

- Double jacket for controlled temperature regulation

- Temperature measuring point in the lid

- Dosing of liquids during mixing

- Data recording and evaluation

- Extended stainless steel design of the container mixer

- Special coating

- Coatings

- ATEX/NEC execution

- Remote maintenance

- 360° cloud monitoring (MIXACO Control Center)

Revolution™ Mixer Sizes. We will gladly advise you.

Parameters: Useful Volume 50 % – Bulk Density 0.5 kg/Ltr.

As the inventor of the container mixer, we at MIXACO are committed to innovation in the industrial mixing technology.

Service & Support. Rely on our experienced technicians.

Mixer Quotation Configurator: Just 2 minutes to the perfect mixer for your raw materials.

Simply tell us your requirements and we will recommend you the optimum mixer for your raw materials and applications. Use our configurator.

With your details on quantities, mixtures, temperatures, additional functions and other information, we will prepare a customized quotation for you.

More than mixers. Holistic customer care for over 55 years.

Test mixer free of charge and without obligation

Test our mixers in our test center – with your own raw materials, of course.

Learn More

Mix & Process Consulting

Have your mixing process checked by our mixing professionals – free of charge & no obligation.

Learn More

The MIXACO Technical Center

In our test centers we can optimize all parameters for your compound.

Learn More