PVC MIXING FACTS: FACT #4

The Perfect Vortex – Bread and Butter in PVC mixing

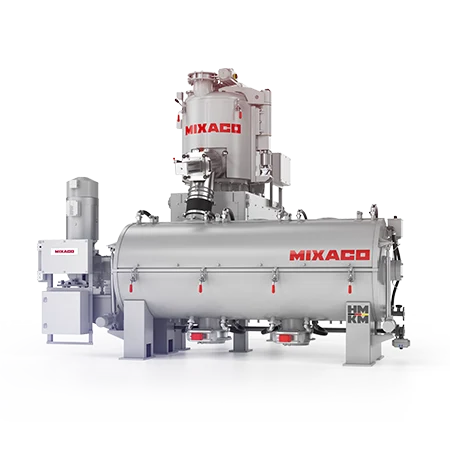

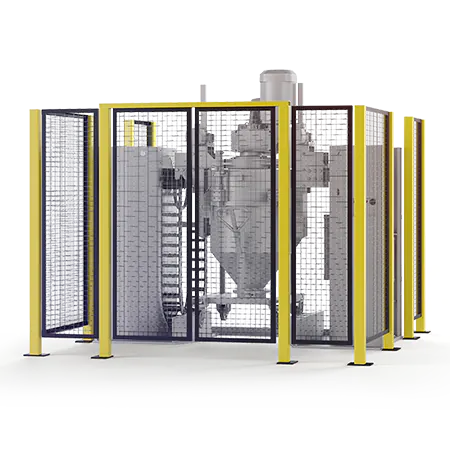

When it comes to high-quality and high-performance mixing, there is more than just raw materials in a bowl with tools.

What defines High-Quality?

In various applications different PVC stabilizer systems are used. In most instances, there is a specific reason to use a special PVC stabilizer system. Stabilizer systems that exist over the world e.g.:

- Bulk density of the blend

- Color dispersion

- Homogeneity

- No stress on the material

- No build up over time

- Rheology

Therefore, High-quality means consistency batch to batch over a long period of time.

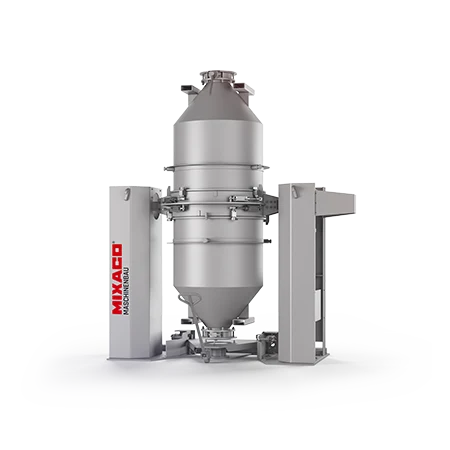

What is the Mixing Vortex?

The task is to combine High-Quality with High-performance. In PVC mixing that means more than 10 batches/h with a superb efficiency. When the desire is to obtain these outstanding performances; the name of the game is easy to guess, yet hard to achieve: The Perfect Mixing Vortex.

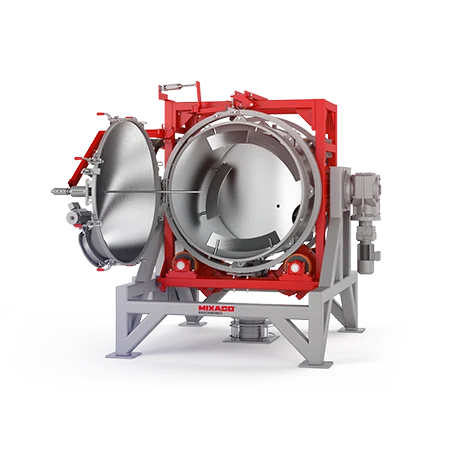

In a vortex, there are different movements (combined vectors). The bottom blade mainly creates a vertical upwards movement and pushing the material to the sides, while the middle tools only create a radial force.

What defines High-Performance?

- Quick

- Throughput

- Energy efficient

The task is to combine High-Quality with High-performance. In PVC mixing that means more than 10 batches/h with a superb efficiency. When the desire is to obtain these outstanding performances; the name of the game is easy to guess, yet hard to achieve: The Perfect Mixing Vortex.

In a vortex, there are different movements (combined vectors). The bottom blade mainly creates a vertical upwards movement and pushing the material to the sides, while the middle tools only create a radial force.

Due to the velocity of the blades, a centrifugal force is created (radial vector). The material gets pressed to the side walls of the bowl and a vacuum is created in the middle. Therefore, the material is dragged to the shaft (horizontal vector) and pulled down (vertical vector), which creates the Vortex. This is enhanced by the special engineered bowl design. In addition, turbulences created by the mixing tools improve friction and blending performance.

How to Influence the Vortex?

The Vortex can be affected by many factors during the mixing process and it is important to know the influences of each of these factors. Some of the most common and easiest practices are explained:

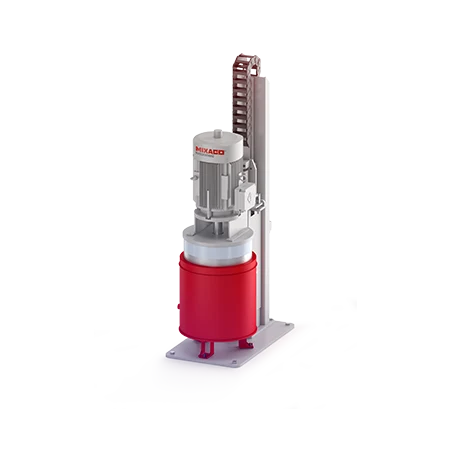

Tip Speed

An easy way to control the vortex is the tip speed of the mixing tools. By changing the speed, the centrifugal force is strongly affected. The perfect Tip Speed depends on the raw materials, blade, and vessel design. The best range of Tip Speed is always mentioned by the supplier.

Tip Speed too low (<20 m/s)

If the Tip Speed of the blades is too low, there is no vacuum created in the middle of the bowl and no horizontal movement. Additionally, many times this will cause the mixer to start vibrating badly.

Tip Speed too high (>35-40 m/s)

If the Tip Speed is too high, the material is pushed up and to the side walls, while creating a huge vacuum in the center. The material will have no top-down movement and a high radial motion. This is called “Donut-Mixing”, where the quality of the blend decreases significantly.

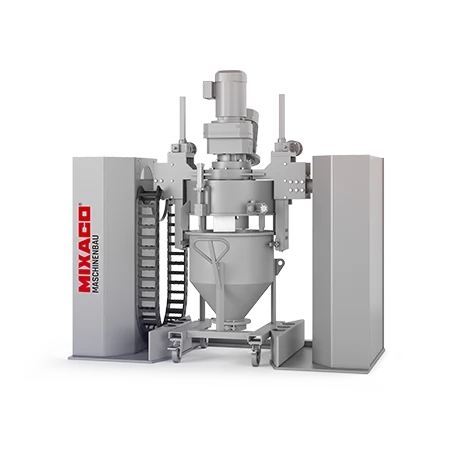

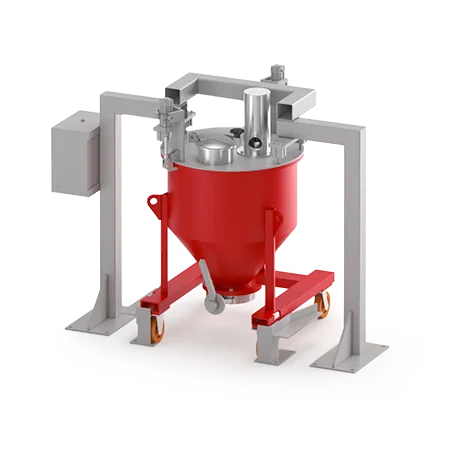

Filling Level

The filling level of the heating mixer is an important parameter in creating the best Vortex. In general, the heating mixer is designed to work with a certain amount of material inside. The useful and recommended volume in MIXACO is 85%. Based on this, the vessels, tools, and motors are engineered.

Underfilled

With a low filling level, the mixer cannot create much downforce. As a result, the blend is pushed upwards and remains at the top of the vessel and the tools are moving without touching much material. The mixing effect is very less.

Overfilled

The Vortex needs a space to move (free volume), especially when it heats up the PVC particles get bloated and use more volume. If the mixer is overfilled, the vortex will not move efficiently and there is a danger of blowing the filter or lid connections.

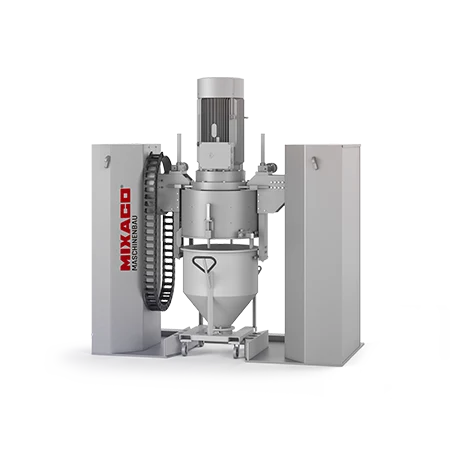

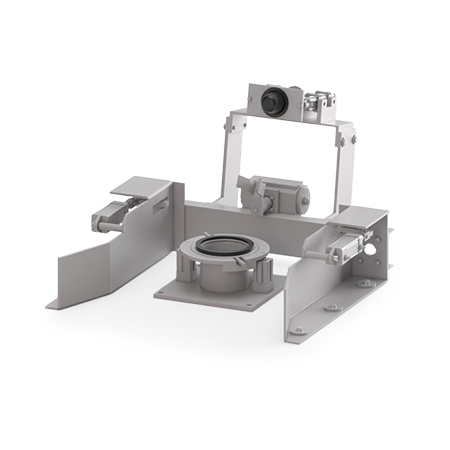

Blades

A more challenging way to affect the Vortex is by changing blade design or enhancing the blade configuration.

Blade Design

There are a lot of different blade designs on the market. The truth of the matter is most of the current designs are just revisions of the old designs. The revised and newer blade designs achieve a better vortex.

Blade Configuration

If the blend used is very light or has a big spread of different bulk densities, it is helpful to change the blade configuration. Light materials tend to keep at the top of the mixer and do not homogenize well in the whole blend. Moreover, this can occur with very fluidized blends. If so, the blades can be lowered to achieve more space for the materials to collapse in the center of the bowl creating the best vortex.

The Ideal Vortex

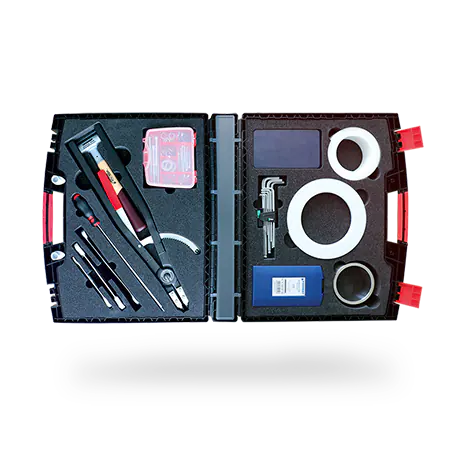

Para más información, estamos a su entera disposición.

Nicolas Gehring

Ventas PVC

MIXACO

Dr. Herfeld GmbH & Co. KG

Niederheide 2

58809 Neuenrade

+49 (0)2392 9644-32

sales@mixaco.de