Powder Mixer

From plastic powder to metal powder. Mix 5 to 10,000 liters of powder without breakage, dust and heat.

MIXACO Powder Mixer – also for your products.

Advantages of our powder mixers. From laboratory powder mixer to large-scale mixing plant.

MIXACO powder mixers are available in all sizes: Laboratory mixers for powders for small batches and product development from 5 liters up to mixers for 10,000 liter batches.

Our powder mixers can realize the most diverse mixing applications for the most diverse industries. These include all types of food powders, powders for pharmaceuticals, powdered raw materials for cosmetics, chemical or even metal powders, vitamin powders or minerals for animal feed, color powders for plastics production, powders for 3D printers, and also ultrafine dusts. MIXACO powder mixers mix all kinds of powder premixes.

MIXACO powder mixers are also suitable for very sensitive powders, which are mixed gently, quickly and homogeneously. Our powder mixers also mix filigree particles without wear, breakage, dust formation or static charging.

Low-energy and temperature-neutral mixing guarantees the integrity of sensitive particles in the powder mixer. Likewise, powder mixers can be heated or cooled.

You can add precise liquids to the powder mixtures in the MIXACO Powder Mixer. These are sprayed in and distributed completely evenly on the powder without the liquid contaminating the interior of the mixer.

- Excellent homogeneity

- Preservation of particle integrity

- Perfect mixing possible between 2 – 6 minutes

- Fast and easy cleaning

- Low energy consumption

- Vertical or horizontal powder mixers

- Low maintenance requirements and low-cost, usage-dependent maintenance

- Special surfaces for food products

- Dust-free discharge stations

- Double jacket designs for temperature control or cooling of the mixing material

- Short mixing times

- Realize several process steps in one mixer: mixing, moistening, flavoring, coating, melting, etc.

- High throughputs, rapid emptying and quick recipe changes

- Batch tracing possible

- Optimum emptying of containers

- Variable filling level

- No dead spaces or cavities in the interior of the mixer

- No product contamination due to closed mixing chamber

- Batch sizes of our mixers from 5 to 10,000 liters

- Powder for cosmetics (make-up, eye shadow, lipstick, blush, etc.)

- Mixing quality is guaranteed even with difficult components – for end products of consistent quality

- Extremely gentle mixing – even without heating if required – allows the most sensitive raw materials to be homogenized

- Gentle mixing of fragile powders (for example filigree effect pigments) without breakage or dust formation

- Our powder mixers convince by simple and very safe handling

- Minimal cleaning effort for fast recipe changes: mixing elements and mixing tools are easily accessible and can be dismantled

- Proven, low-maintenance machine technology “Made in Germany” guarantees minimum downtime and high availability of the production plant

- Powder mixers in ATEX executions

- Optimum dispersion and free powder flow

- Time-saving, hygienic design

- Mixing parameters individually adjustable

- Joint product development and mixing optimization in our test centers

- Innovative monitoring of the powder mixers via the MIXACO Control Center

Mixer Quotation Configurator: Just 2 minutes to the perfect mixer for your raw materials.

Simply tell us your requirements and we will recommend you the optimum mixer for your raw materials and applications. Use our configurator.

With your details on quantities, mixtures, temperatures, additional functions and other information, we will prepare a customized quotation for you.

What powders can be mixed? All!

The range of powders that can be mixed in our powder mixers is almost infinite. Powders are a component for the production of countless products in a wide variety of industries, for example:

- Detergents and cleaning agents (agglomerates and liquid additives)

- Milk powders (excellent solubility, no breakage and no lumping of fatty milk powders)

- Instant powders such as cocoa, chocolate and coffee powders (while ensuring ideal bulk density and good solubility)

- Coffee powders (no lump formation)

- Ceramic powders (gentle processing without damaging the mixed material and easy application of liquids)

- Battery masses and powders along the battery supply chain

- Sugar

- Silicates (guarantee of absorption and adsorption enables wear-free processing)

- Metal powders and granules (wear-free processing with good explosion suppression)

- Artificial fertilizers (fracture-resistant processing with coating possibility)

- Plastics, polymers (fracture-resistant processing by soaking with liquids)

- Herbs and spices (break-resistant processing)

- Powders for cosmetics (make-up, eye shadow, lipstick, rouge, etc.)

- Farm animal feed and pet food (e.g. coating of feed with vitamin powder)

- Food supplements, protein powders, vitamin powders, minerals fertilizers, insecticides, pesticides, herbicides

- Powder metallurgy and fine ceramics

- Plastic powders for 3D printers

- Powder emulsifiers

- Color powders and pigments

- Powder coatings

- Masterbatches, color masterbatches

- Powder mixtures for plaster, concrete, screed, plaster, cement

- Dusts

- Powders for fire extinguishers and fire retardant products

- ABS, PS, biopolymers, thermosets, EPS, rubber recycling and moldings, MIM / CIM, PE-Xa, polyolefins, POM, PTFE, powder rubber, powder coatings, PVB, PVC-P: film, flooring, LVT, cables, hoses, PVC-U: Pipes, profiles, sheets, film, injection molding, foams, recycled products, foams, TPE / TPU, UHMW / HMW-PE, WPC: PE, PP, PVC, PLA, starch, PPC, cellulose compounds, natural fiber compounds

As the inventor of the container mixer, we at MIXACO are committed to innovation in industrial mixing technology.

Mixing Methods. Various mixing techniques can be used.

Powder mixers from MIXACO are suitable for a wide variety of mixing methods and applications when processing a wide variety of powders:

- Homogenization of bulk materials

- Agglomeration

- Intensive deagglomeration

- Wetting of particles

- Modification of functions and properties

- Gentle homogenization

- Improvement of product quality

Additional Options. Individual powder mixers for your powders and raw materials.

MIXACO powder mixers are available in various shapes and sizes and are suitable for countless mixing techniques and processing methods. With batch sizes from 5 to 10,000 liters, our mixers scale flexibly with your individual requirements.

Via various additional options, our powder mixers are perfectly adapted to the processing of your powders and raw materials:

- Dedusting

- Temperature measurement

- Ventilation and charging during the mixing process

- Dosing / spraying / injection of liquids and gases during the mixing process

- Mixing head cooling

- ATEX executions

- Data recording and evaluation

- Remote maintenance

- Hygienic design

- WIP – CIP Cleaning

- Heating, drying, cooling

- Batch mixer / discontinuous or continuous mixer

- Mixing, drying, coating under vacuum

- etc.

FAQ. All about powder mixers.

Powder mixers are used in a wide variety of industries, because powders are relevant for the manufacture of countless products: Food, animal feed, cosmetics, tablets, plastics, paints, powder coatings, minerals, metals, rubber, PVC, detergents, cement, plaster and many more.

A powder mixer mixes dry and moist powders, but also granules, flakes and dusts. Powders have a wide variety of physical properties and are more or less sensitive during processing. Too much heat during mixing or too intensive mixing can impair the quality or lead to breakage of the particles and to dust formation.

A good powder mixer also mixes sensitive and fragile particles without impairments. Due to the large number of different powders, a powder mixer should be able to be configured individually for each powder. Different tools and additional options, such as liquid injection or gassing, are important to be able to process each powder mixture optimally.

Depending on the powder type, batch size, throughput, manufacturing process, etc., different powder mixers are used:

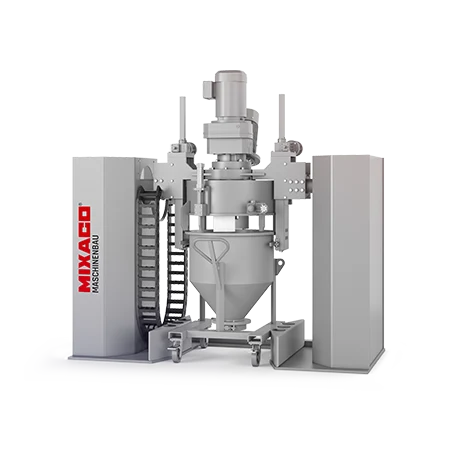

- Vertical powder mixers

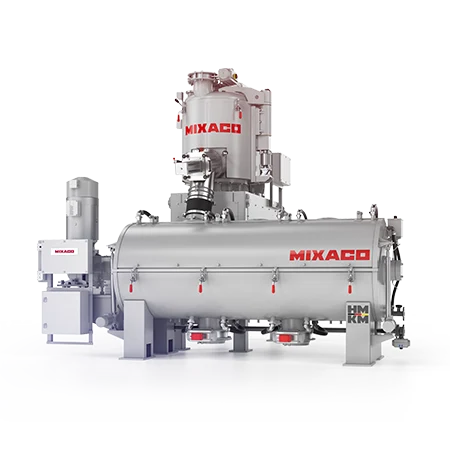

- Horizontal powder mixers

- Continuous powder mixers

- Discontinuous powder mixers

- Single-shaft mixers

- Paddle mixer

- Inline mixers

- Batch mixer

- etc.

Usually, powder mixers are differentiated according to the shape of the mixing vessel into v-shaped mixers or conical mixers and cylindrical mixers.

For the laboratory or product development, powder mixers are suitable as laboratory mixers, with which small quantities up to about 12 liters can be mixed. For larger batches and throughputs of up to 100,000 liters per hour, powder mixers are available in many different size gradations up to mixing plants as high as a house.

Powder mixers are very common, for example, in the manufacture of pharmaceutical products such as tablets, capsules and pills. In this process, a powder batch is mixed from the basic substances active ingredient, filler and other additives by means of powder mixers for further processing, in order to subsequently process them on capsule filling machines or tablet presses into the end product.

In the manufacture of pharmaceutical products, powder mixers are often used for mixing after the powder or active ingredient has been dried.

Various factors must be considered when selecting the correct powder mixer:

- Raw materials

- Quality of the final products

- Heat input

- Mixing intensity

- Size, shape and moisture content of the powder particles to be mixed

- Production equipment

- Integration into production processes

- Hygiene regulations

- Mixing accuracy

- Approved construction materials

- Energy consumption

- Throughput rate

- Discontinuous or continuous powder mixer

In particular, the powder properties determine the optimum mixer for uniform mixing:

- Powder sticky or free flowing

- Powder particles fine or coarse

- Mixing of different particle sizes and textures

- Volume of powder

- etc.

The type of powder processing also influences the choice of the right powder mixer. Which processes are used:

- Homogenize

- Agglomerate

- Deagglomeration

- Dispersing

- Vacuum drying

- Humidification

- Melting

- Coating

- etc.

Also consider factors of cleaning and hygiene when selecting the powder mixer:

- Prevent cross contamination

- Food safe surfaces

- Cleaning of the powder mixer between batches

- Fast drying possible

- Cleaning according to food hygiene

- Airtight mixing process necessary

- etc.

Service & Support for our powder mixers. You can rely on us and our experienced technicians.

For further information please do not hesitate to contact us.

Guido Brand

Sales & Marketing

MIXACO

Dr. Herfeld GmbH & Co. KG

Niederheide 2

58809 Neuenrade

Germany

+49 (0)2392 9644-210

sales@mixaco.de