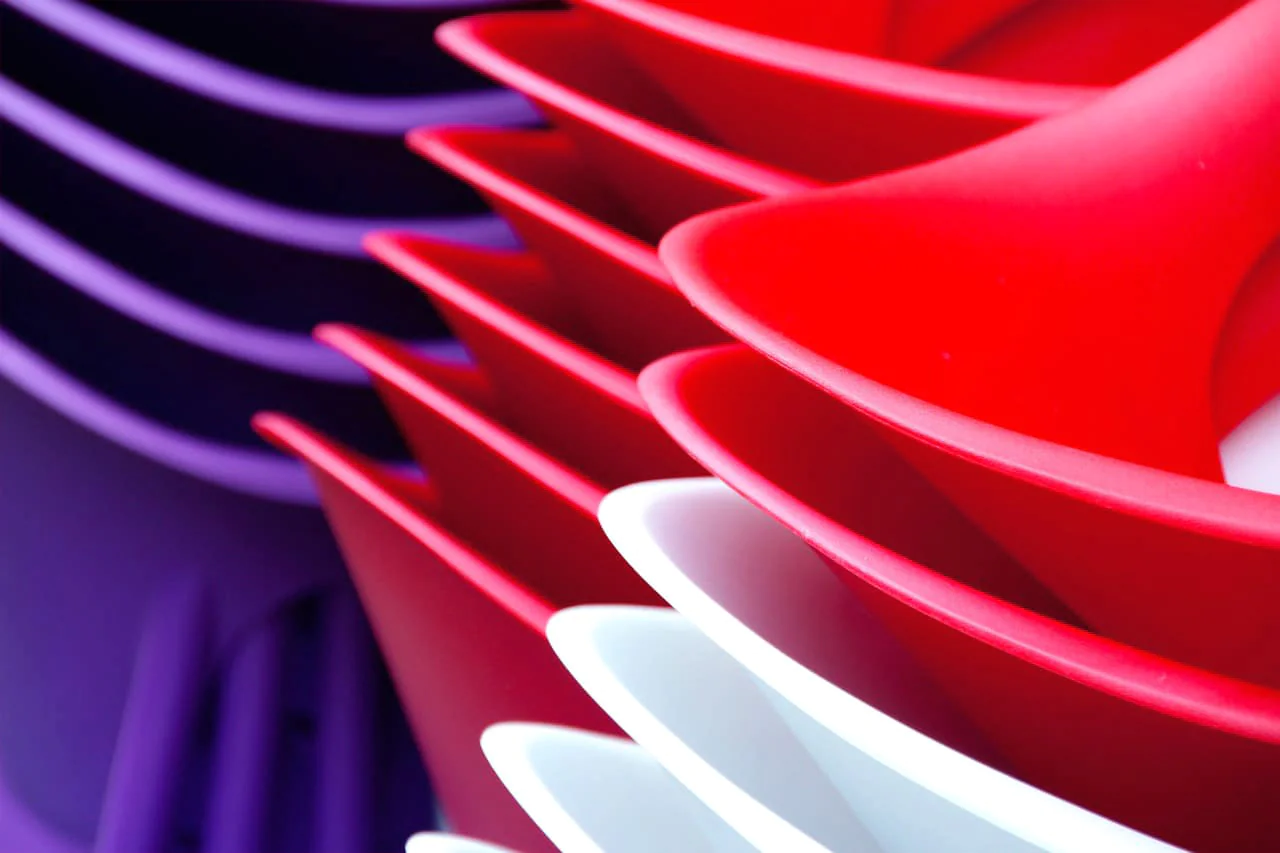

Industrial Mixer for Plastics

Industrial mixer for plastic production. Fast recipe changes and high throughputs.

Stationary Mixers and Container Mixers. Mixing plastics perfectly.

The plastics industry places particularly high demands on mixing technology. In the multitude of materials and their applications, new mixing tasks have to be realized or formulations optimized again and again.

An optimal mixing result is the basis for the right end product. For decades, MIXACO has been delivering innovative solutions that have sustainably improved the production of a wide range of plastic products.

In order to achieve the right plastic compounds, for example in masterbatches, in compounding or with additives, trials are an indispensable part of our customers’ product development.

In our technical center, we work with you to develop the right solutions and processes for your production from factors such as the formulation, the mixing process, the mixing parameters or the use of tools.

The trials not only consider aspects such as the economical use of pigments or additives. In the case of dry blends, for example, the desired dispersion and homogeneity can be achieved depending on specific requirements.

The efficient input of energy or temperatures, for example during agglomeration, can also be precisely defined here. The possibilities are versatile and always a challenge, but challenge us, we deliver you high flexibility.

Our specialists work with many years of experience from several thousand trials for the appropriate implementation. This results in mixing solutions that can be carried out with process reliability and high throughput.

Advantages

- High availability due to high-quality and proven machine technology

- Innovative strength to continuously optimize mixing technology

- Low idle times through quick and easy cleaning

- High mixing quality due to optimal handling of the material

- Low energy consumption through innovative designs and tools

- Optimal application solutions through customized tests and mixing processes

- High flexibility through optimized handling of machines and containers

- High product variety due to wide range of machines for all batch sizes

- Easy operation due to innovative machine concept

From ABS to WPC. We mix all Plastics.

Our mixers can be flexibly optimized for mixing countless plastics and their applications, for example:

- Acrylonitrile butadiene styrene (ABS)

- PTFE

- Polyoxymethylene (POM)

- Polyethylene (PE XLPE)

- Polycarbonate (PC)

- Polypropylene (PP)

- Polyvinyl chloride (PVC)

- WPC (Wood-Plastic-Composite)

- SPC (Stone-Plastic-Composite)

- Carbon

- Glass fiber plastic (GFK)

- Polystyrene (PS)

- Polyurethane (PU/PUR)

- Polyethyleneterephthalate (PET)

- Polymethylmethacrylate (PMMA)

- Polybutyl terephthalate (PBT)

- Styrene-acrylonitrile copolymer (SAN)

- Polyamide (PA)

- Phenoplastics

- Polyester resins

- Polyurethane resins

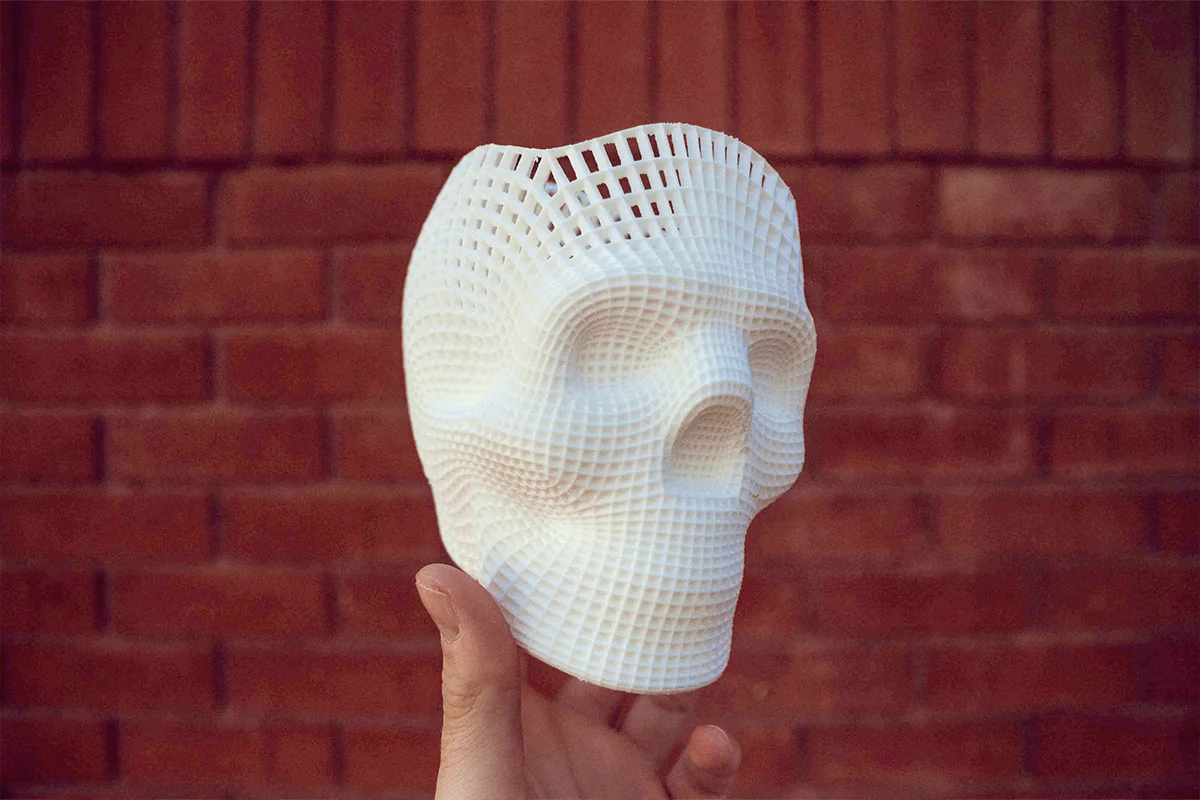

- Plastic powders for 3D printing

- Polymers

- Additives

- Blends

- Masterbatches

- Metal Injection Molding (MIM)

- Ceramic Injection Molding (CIM)

- And Other

Processes and functions. Optimal processing of classic to novel plastics.

MIXACO has profound know-how in plastics mixing. We master all applications for all common products and processes in the plastics industry.

If the solution for a new idea is still missing, we will help you develop it immediately. Our plastic mixers mix perfectly, for consistent quality.

Modern plastics are continuously evolving. With the know-how of our specialists and powerful machines, these innovations can be brought to production maturity more quickly. That’s why leading companies around the world value MIXACO’s efficient and process-reliable solutions.

Applications

- Dispersing, homogenizing, agglomerating

- Mixing of granulates, flakes, powders incl. liquid injection

- Exact gravimetric or volumetric dosing

- Packaging via additives such as stabilizers, chalk, blowing agents, accompanying agents or colorants

- Blending plastics with other polymers or rubber to form polyblends

- Mixing inorganic material such as fillers, glass fibers or rock flour into the plastic

- And many more

Additional functions. Mixing plastics individually.

Whether stationary heating-cooling mixer or flexible container mixer, we can configure the perfect mixer for your plastics applications via numerous additional options.

- Container weighing

- Dedusting

- Temperature measurement of the mixed material

- Aspiration heating mixer / jet-filter cooling mixer

- Ventilation and feeding during the mixing process

- Dosing of liquids and gases during the mixing process

- Data recording and evaluation

- Remote maintenance

- Compatibility with existing plants

- Advanced stainless steel design

- Wear protection of the tools

- Possibility of addition in mixing position

- Special coating

- Coatings

- AGV (automatic guided vehicle) compatibility

- ATEX/NEC execution

- MIXACO Control Center

Mixer Quotation Configurator: Just 2 minutes to the perfect mixer for your raw materials.

Simply tell us your requirements and we will recommend you the optimum mixer for your raw materials and applications. Use our configurator.

With your details on quantities, mixtures, temperatures, additional functions and other information, we will prepare a customized quotation for you.

Service & Support for our plastic mixers. You can rely on us and our experienced technicians.

More than mixers. Holistic customer care for over 55 years.

Test mixer free of charge and without obligation

Test our mixers in our test center – with your own raw materials, of course.

Learn More

Mix & Process Consulting

Have your mixing process checked by our mixing professionals – free of charge & no obligation.

Learn More

The MIXACO Technical Center

In our test centers we can optimize all parameters for your compound.

Learn MoreFor further Information just get in contact with us.

Markus Frantzen

General Manager MIXACO USA

MIXACO USA LLC

1784 Poplar Drive

Greer, SC 29651

+1 (0)864 331-2320

+1 (0)864 331-2321

info@mixaco.com