Industrial Mixer for Chemical Products

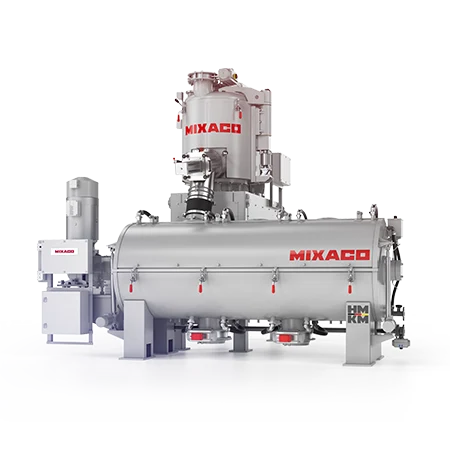

Different applications in one Mixer. Tailor-made mixing of demanding chemical products.

Stationary Mixers and Container Mixers. Mix chemical products perfectly.

Product developments in the chemical industry are picking up speed. With the know-how of our specialists and high-performance industrial mixers, these innovations can be brought to production maturity more quickly.

That’s why leading chemical companies around the world value MIXACO’s efficient and process-reliable mixers.

Our mixers for the chemical industry are characterized by very short mixing times compared to standard mixing systems on the market.

The intensive and excellent homogenization of the mixed material is often achieved in a period of 3-6 minutes of mixing.

Benefit from our superior mixing technology “Made in Germany” and our many years of experience in mixing chemical raw materials.

Convince yourself of the advantages of our industrial mixers for the production of chemical products:

Advantages

- Dust-free discharge stations

- Double jacket executions for heating or cooling of chemical components

- Airtight mixing chamber without dead spaces

- Execution according to hygiene standards of the chemical industry

- Mixing in less time than conventional mixing systems – starting from 3 min mixing time

- Homogenize dry & wet formulations in highest quality

- Multiple process steps in one mixer: mixing, moistening, coating / calendering

- High throughputs, rapid emptying and fast formulation changeover

- Batch tracing possible

- Very high degree of residual emptying

- Variable filling level

- No product contamination due to closed mixing vessel

- Batch sizes from 6 to > 10,000 liters

- Mixing quality guaranteed even with difficult components

- For end products of consistent quality

- Extremely gentle mixing

- Mixing without heating – for the most sensitive chemical raw materials

- Minimal cleaning effort for fast recipe changes

- Mixing elements and mixing tools easily accessible and demountable

- Low idle times due to fast and easy cleaning

- Solid and low-maintenance machine technology “Made in Germany”

- High availability of the production plant

- Specially coated mixing tools for long service life

- Various ATEX executions available

- Low energy consumption due to innovative designs and tools

- Optimal application solutions through intensive test mixing

- Simple & safe operation of the industrial mixers

- Mixers in individual special designs

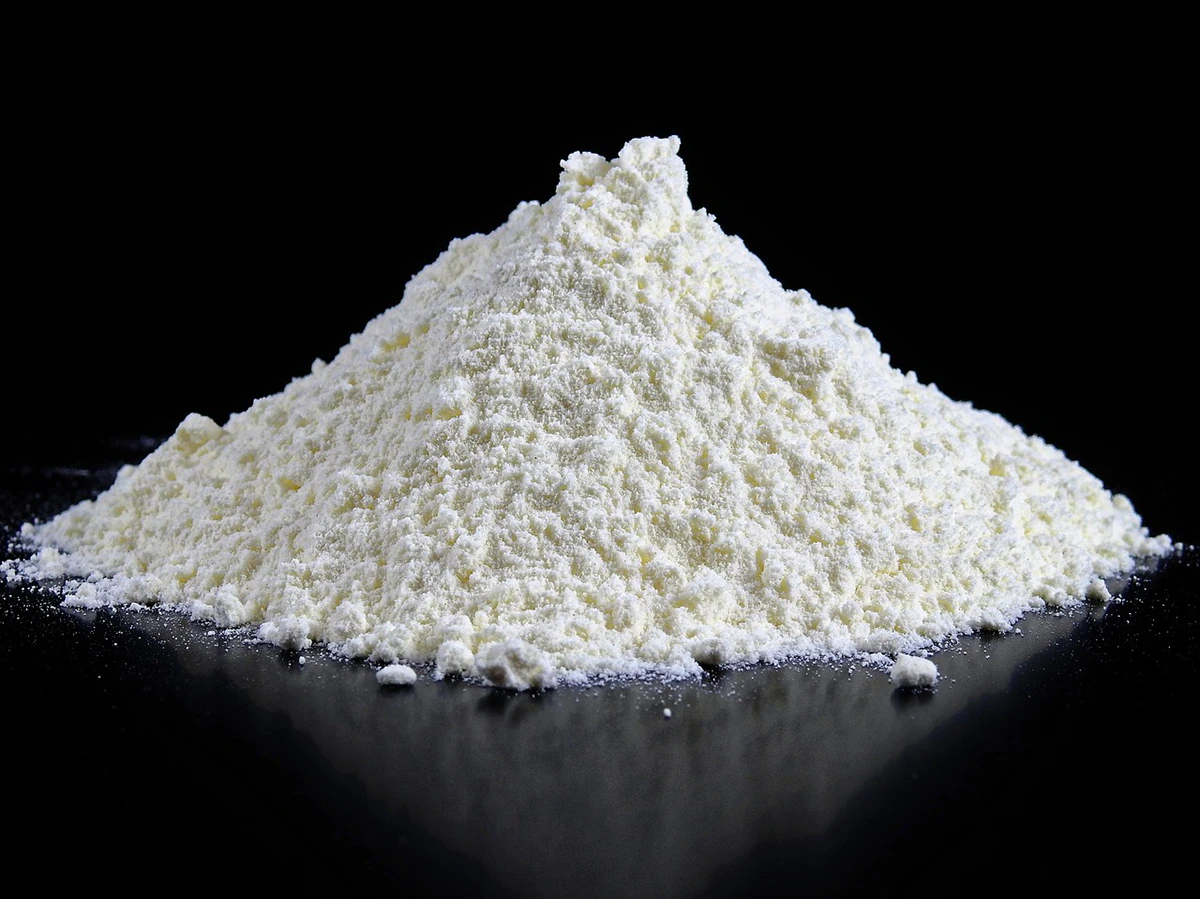

From agricultural chemistry to nanoparticles. We mix all solid chemicals.

MIXACO has profound know-how for mixing in the chemical industry. We master all procedures for all common products and processes in the processing of chemical products.

Here are some examples of raw materials and applications of our chemical mixers:

- Masterbatches

- Additives

- Compounds

- Organic and inorganic pigments

- Colors

- Resins

- Polyols

- PTFE ︎

- EPS

- XLPE

- PET

- PE

- PP

- Titanium dioxide

- Silicone dioxide

- Iron / Metal oxides

- Solvent

- Fertilizer

- Fungicides

- Pesticides

- Herbicides

- Lubricants

- Sealants

- Surfactants

- Detergents

- Battery powders

- Metal powders

- Powder coating

- Metallic powder coatings

- Aluminium powder

- Fire extinguishing powder

- Flame retardants

- Fillers

- Base materials

- Catalysts

- Ceramic bodies (CIM)

- Metals (MIM)

- Minerals

- Organic materials

- Carbon black / carbon

- Salts

- Silica

- Starch

- Stearate

- Toner

- Talc

- Abrasive

- Hydrogen Peroxide

- Ethylene Diamine Disuccinate

- DEEDMAC

- Applications for cosmetic products (mixing for eye liner, lipstick, blush, eye shadow etc.)

- Applications for pharmaceutical products (powder blending for tablets, pellets and capsules, tablet coating etc.)

- SAP (Super Adsorbent Powder) for use in sanitary products

- Stabilizers

- Nanoparticles

- Crystalline mixtures

- Ceramics for electronics and refractory materials

- etc.

Processes and Functions. Mixing various chemical products.

Our mixers deliver the full range of customized mixing and blending processes for the wide variety of products used in the chemical industry.

Different product properties and formulations always require individual handling, mixing and blending processes. With a holistic view of the requirements of the chemical industry, the necessary processes can be mastered safely.

For optimum mixing results, we work with our customers to find the most suitable process. Whether homogenizing, dispersing, preparing or coating: Individual mixing parameters are developed for each chemical product.

All machines are available for this purpose in our test center. Here, for example, the addition of additives or pigments can be defined very precisely in order to function reliably and process-safely in industrial practice later on.

In applications such as compounding, the parameters for mixing and suitable tools are also specified. In addition, factors such as dust-free working and consistent cleanliness in the production processes must also be taken into account.

In addition to first-class mixing results, fast recipe changes are also crucial. Here, MIXACO has been the innovation leader for over 50 years.

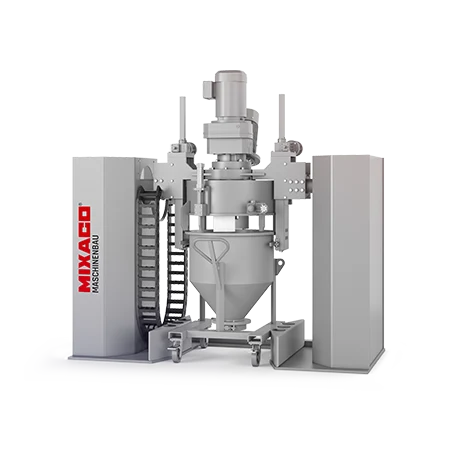

When using the container mixer, the mixing container is also a transport container. After mixing, the finished mixture can be immediately rolled to the next station for further processing.

Before the next recipe changeover, therefore, only the mixing head needs to be cleaned. This solution simplifies and accelerates the entire processes considerably.

With over fifty years of experience in process engineering and the in-depth know-how of our experts, our customers from the chemical industry achieve customized results and market maturity more quickly.

At the same time, we work together with you to continuously optimize existing processes related to industrial mixing in the chemical industry.

Our mixers offer solutions for fine chemistry, synthesis and chemical reaction technology, for example:

- Dispersion, deagglomeration, coating

- Agglomeration, grain enlargement

- Metal Injection Molding (MIM) ︎

- Ceramic Injection Moulding (CIM)

- Dispersion of pigments, additives, polymers, polyols, plastics, etc.

- Dispersing

- Gentle homogenization and intensive mixing in the same mixer

- Hydrophobization of rare earths

- Rounding pellets

- Coating of fertilizer

- Mixing of rubber

- Processing of ceramic powders

- Breaking up of solids

- Reaction acceleration

- And much more

Options. Mix Chemicals Individually.

Via various options, our mixers are perfectly adapted to the production of your chemical products:

- Dedusting

- Temperature measurement of the mixed material

- Ventilation and feeding during the mixing process

- Dosing of liquids and gases during the mixing process

- Data recording and evaluation

- Remote maintenance

- Compatibility with existing plants

- Advanced stainless steel design

- Wear protection of the tools

- Possibility of addition in mixing position

- Special coating

- Coatings

- AGV (automatic guided vehicle) compatibility

- ATEX/NEC execution

- MIXACO Control Center

- Among others

Mixer Quotation Configurator: Just 2 minutes to the perfect mixer for your raw materials.

Simply tell us your requirements and we will recommend you the optimum mixer for your raw materials and applications. Use our configurator.

With your details on quantities, mixtures, temperatures, additional functions and other information, we will prepare a customized quotation for you.

Service & Support for our Industrial Mixers. You can rely on us and our experienced technicians.

More than mixers. Holistic customer care for over 55 years.

Test mixer free of charge and without obligation

Test our mixers in our test center – with your own raw materials, of course.

Learn More

Mix & Process Consulting

Have your mixing process checked by our mixing professionals – free of charge & no obligation.

Learn More

The MIXACO Technical Center

In our test centers we can optimize all parameters for your compound.

Learn MoreFor further Information just get in contact with us.

Ed Ford

Sales Manager USA

MIXACO USA LLC

1784 Poplar Drive

Greer, SC 29651

+1 (0)864 331-3319

+1 (0)864 331-2321

info@mixaco.com