Industrial Mixers from the Innovation Leader

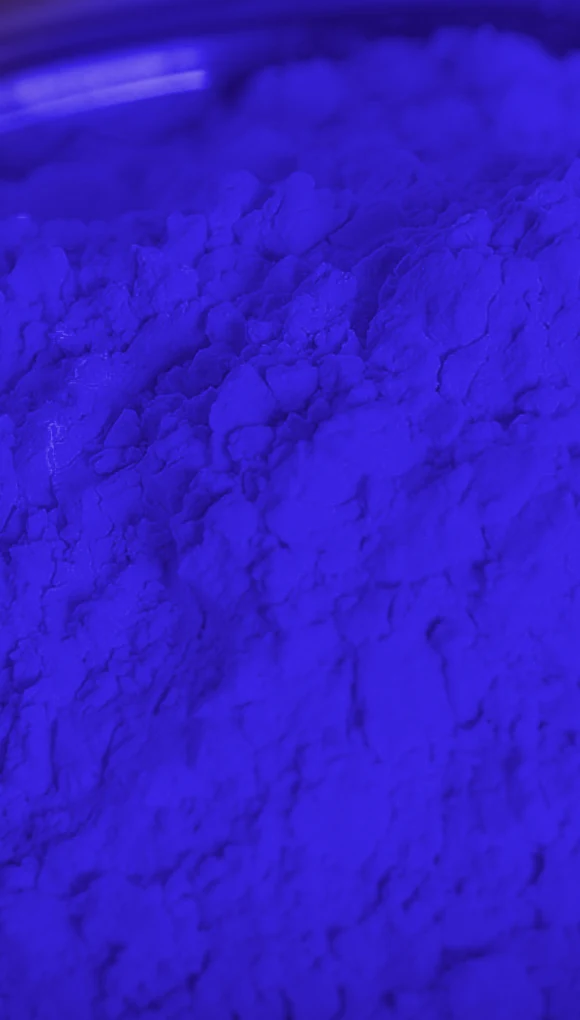

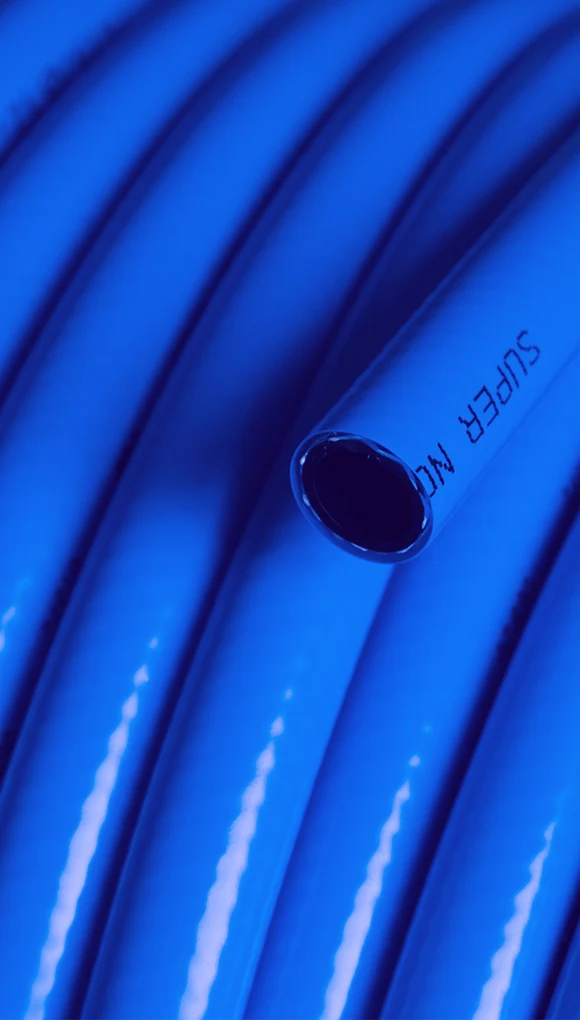

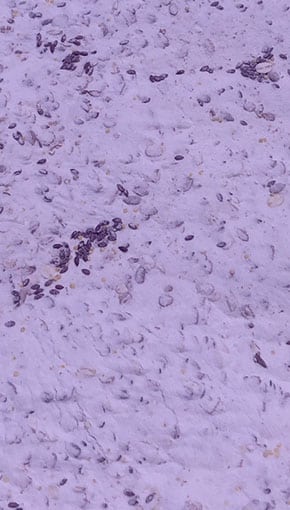

Our Mixers Are Used forPowders.

Our Mixers Are Used forOur passion: optimal mixtures. Whatever you want to mix, we have the perfect industrial mixer for your raw materials.

Our Highlights

Mixers for all industries. All over the world, leading companies from many industries rely on mixers from MIXACO. And there are good reasons for that.

Why MIXACO?

Superior Machine Technology

Benefit from our unique know-how gained from over 55 years of experience in industrial mixing technology. Many of our mixers have been in use for over 30 years. Let yourself be inspired by the German engineering skills of a genuine traditional company.

We are the Innovation Leader

We have been setting standards in mixing technology for decades. We not only invented the first container mixer. With innovative products such as the i4 container mixer, the laboratory heating mixer or 360° cloud monitoring, we continue to set new standards in mixing technology.

Customized Mixers

Our team is united by a fascination for turning technical challenges into efficient machine solutions. Thanks to flat hierarchies and short decision-making paths, we are always able to react quickly and flexibly to individual requirements.

More than mixers. Holistic customer care for over 55 years.

Test mixer free of charge and without obligation

Test our mixers in our test center – with your own raw materials, of course.

Learn More

Mix & Process Consulting

Have your mixing process checked by our mixing professionals – free of charge & no obligation.

Learn More

The MIXACO Technical Center

In our test centers we can optimize all parameters for your compound.

Learn More