Industrial Mixer for Batteries & Battery Production

Battery

Lithium-ion

Electrode manufacturing

Anode

Cathode

Premix

Dry coating

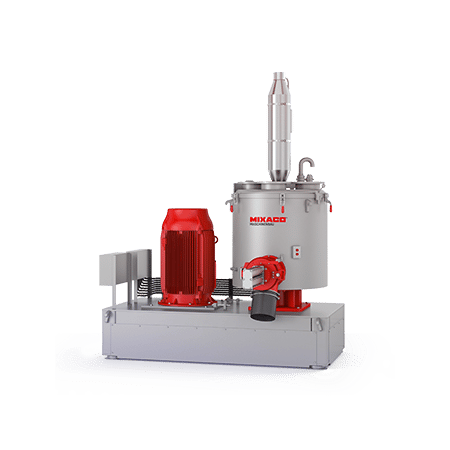

Industrial mixer for battery production. Perfect raw material mixing and treatment – especially for dry or semi-dry processing of electrodes.

High performance mixers – always the right choice. Mixing battery raw materials perfectly.

It all starts in the lab… and is needed in production in no time at all.

Product developments in the battery industry are picking up an extremely fast pace. New developments in raw materials, battery chemistry, processing and production methods are breaking through every day.

With the know-how of our specialists and high-performance industrial mixers, these innovations can be quickly and reliably transferred from the laboratory to production.

In our technical center, we work with you to develop the right solutions and processes for your production from factors such as the formulation, the mixing process, the mixing parameters or the use of mixing tools.

That’s why leading chemical and energy storage companies around the world value MIXACO’s efficient and process-reliable mixers already.

Convince yourself of the advantages of our industrial mixers for the production of battery products:

Advantages

- Dry- and semi-dry electrode mixtures without compromises

- Mixers in individual special designs

- Excellent wear protection options available

- Airtight mixing chamber without dead spaces

- Double jacket executions for heating or cooling of chemical components

- Execution according to hygiene standards of the chemical industry

- Homogenize dry & wet formulations in highest quality

- Multiple process steps in one mixer: mixing, densifying, particle shape modifications,…

- High throughputs, rapid discharging and fast formulation changes

- Batch tracing possible

- Variable filling levels

- Batch sizes from 5 to > 10,000 liters

- Mixing elements and mixing tools easily accessible and detachable – adjustable to individual needs

- Solid and low-maintenance machine technology “Made in Germany”

- For end products of consistent quality

- Various ATEX executions available

From active materials to binders and polymers. We mix all battery raw materials.

Our mixers can be flexibly optimized for mixing countless battery raw materials and their applications, for example:

- Lithium Nickel Cobalt Manganese Oxide (LiNiCoMnO2) – NMC or MCM

- Lithium Iron Phosphate (LFP)

- Graphite

- Graphene

- Lithium Titanate Powder

- Silicon Anode Powders

- Carbon Black

- Polytetrafluorethylen (PTFE)

- Polyvinylidene Fluoride (PVDF)

- Styrene Butadiene Copolymer (SBR)

- Fluorethylenpropylen (FEP)

Mixing techniques. Mix even demanding raw material perfectly.

Our mixers are not only capable of performing simple mixing processes, but can also handle a wide range of other processes. In addition to the classic primary process of dry mixing, other processes required in the battery industry can be carried out with our high performance mixers.

In addition to excellent homogenization, MIXACO mixers process and homogenize a wide range of raw materials in the chemical and battery industries. Some of the processes that can be performed in our machines:

Applications

- Modification of particle sturctures

- Rounding of particles

- Heating & cooling of mixtures

- Fibrillization

- Compaction

- Homogenization

- Dispersion

- Agglomeration

- De-agglomeration

- And many more

Options. For Customized Battery Raw Material Mixers.

Numerous additional options allow our mixers to be individually adapted to your battery raw materials and applications.

Side Injection Nozzle

Wear Resistant Probe

Choopers

Liquid Spraying

Sample Pickup

Vacuum Dehumidifying

Nitrogen Blanketing

Lid Tilting

Hinged Lid

Dual Discharge

Spraying on Choppers

Contour Shaped Valve

Semi-Spherical Valve

Wear Resistant Vessel

Deflector

Cooler Weighing

Automatic Greasing

Explosion Safety

Water Cooled Motor

Water Cooled Tools

Vessel Tempering

Closed Loop Heat Exchanger

Dehumidification of the mixture by means of aspiration is crucial for the optimum quality of dry blends. A constant air flow transports the moisture out of the heating mixer to avoid buildup in the mixer.

Jet-Filter

Jet-Filter / Aspiration

Bag Filter Box

Depending on the design, our mixers can be used in potentially explosive dust and gas atmospheres of various ATEX zones by nitrogen inerting or oxygen concentration measurement. A machine acceptance is carried out and documented by an official inspection body or an appropriately certified employee.

The remote maintenance module provides the possibility to access the control of the heating/cooling mixer combinations quickly and securely via a VPN tunnel. This enables our service team to diagnose and rectify faults without having to be on site. This makes data recording and evaluation possible.

Service & Support for our plastic mixers. You can rely on us and our experienced technicians.

Mixer Quotation Configurator: Just 2 minutes to the perfect mixer for your raw materials.

Simply tell us your requirements and we will recommend you the optimum mixer for your raw materials and applications. Use our configurator.

With your details on quantities, mixtures, temperatures, additional functions and other information, we will prepare a customized quotation for you.

More than mixers. Holistic customer care for over 55 years.

Test mixer free of charge and without obligation

Test our mixers in our test center – with your own raw materials, of course.

Learn More

Mix & Process Consulting

Have your mixing process checked by our mixing professionals – free of charge & no obligation.

Learn More

The MIXACO Technical Center

In our test centers we can optimize all parameters for your compound.

Learn MoreFor further Information just get in

contact with us.

Ralph Richter

Chief Process Expert Batteries

MIXACO

Dr. Herfeld GmbH & Co. KG

Niederheide 2

58809 Neuenrade

Germany

+49 (0)2392 9644-524

sales@mixaco.de