Industrial Mixer for Building Materials

Mixers for the production of dry mortar, dry plaster, dry cement & Co. Mix all dry raw materials perfectly.

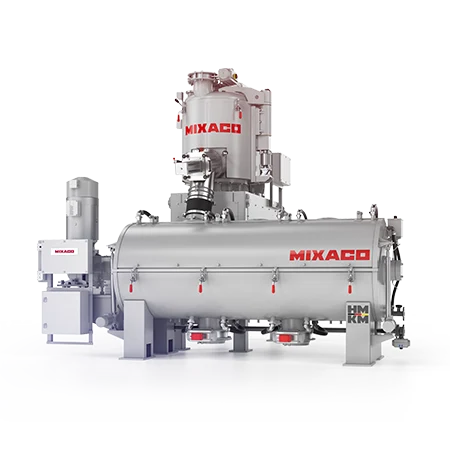

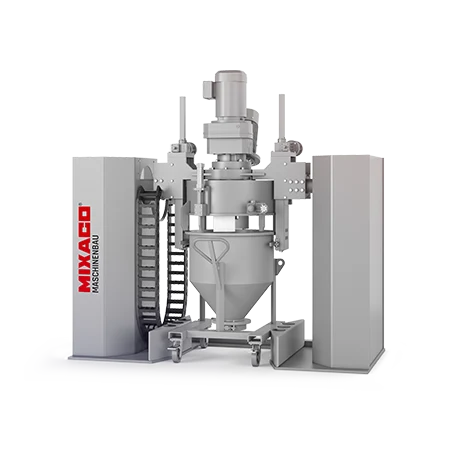

Stationary Mixers and Container Mixers. Mix dry building materials perfectly.

Our mixers for the building materials industry are characterized by very short mixing times compared to standard mixing systems on the market.

The intensive and excellent homogenization of the mixed material is usually achieved within 3-6 minutes mixing time. Extremely gentle mixing – even without heating if required – means that even sensitive additives can be mixed.

We counter the risk of dust explosions of ultrafine mixtures with various ATEX executions. The mixing trials not only consider aspects such as the economical use of pigments or additives. In the case of dry blends, for example, the desired dispersion and homogeneity can be achieved depending on specific requirements.

Mixing temperature-sensitive or challenging building materials

The production of dry mixes for mortar, cement or plaster is characterized by the intensive use of various additives and colors.

A MIXACO mixer can also process sensitive additives. Mixing of hazardous materials and explosive dust mixtures is done according to industry safety standards and ATEX specifications.

From concrete mortar to cement ultra-fine. We mix dry building materials.

Our industrial mixers are ideal for all dry building materials such as mortar, plaster or cement mixed with additives or paints. For example:

Mortar (dry)

- Acryl Cement

- Cement mortar

- Lime mortar

- Lime mortar fat

- Lime mortar hydraulic

- Trass mortar

- Mortar plaster

- Pozzuolana mortar

- Facade mortar

- Colored mortar

- Mortar shrink resistant

- Mortar heat insulating

- Concrete mortar

- Fireclay mortar / fire-resistant mortar

- Gypsum

- Undercoat plaster

- Grout mortar

- Lime plaster mortar

- etc.

Plasters (dry)

- Plastic plasters

- Silicate plasters

- Base plaster

- etc.

Concrete (dry)

- Cement raw, unground

- Pozzolanic cement

- Cement with carbon

- Cement with alumina / high alumina

- Cement containing magnesia

- Cement with calcium aluminate

- Cement white

- Cement colored

- Cement hydraulic

- Cement fast setting

- Cement slow setting

- Cement with low heat of hydration

- Cement water repellent

- Cement acid resistant and corrosion resistant

- Cement sulfate resistant

- Sulfate slag cement

- Cement for cold weather processing

- Cement with fibers / fiber cement

- Cement for masons

- Cement high fine

- Cement for oil drilling

- Cement slurry

- Cement based screeds

- etc.

Further Construction Materials

- Abrasive (dry to viscous)

- Corundum

- Polishing agent (dry)

- Gypsum

- Leveling compounds (dry)

- Resins (dry to viscous)

- etc.

Processes and Functions. Mix building materials individually.

Additional Functions. Mix building materials individually.

Depending on the mixer type, you can configure the perfect mixer for your building material applications via numerous additional options.

- Dedusting

- Temperature measurement of the mixed material

- Ventilation and feeding during the mixing process

- Dosing of liquids and gases during the mixing process

- Data recording and evaluation

- Remote maintenance

- Compatibility with existing plants

- Advanced stainless steel design

- Wear protection of the tools

- Addition possibility in mixing position

- Special coating

- Coatings

- AGV (automatic guided vehicle) compatibility

- ATEX/NEC execution

- MIXACO Control Center

- Among others

Mixer Quotation Configurator: Just 2 minutes to the perfect mixer for your raw materials.

Simply tell us your requirements and we will recommend you the optimum mixer for your raw materials and applications. Use our configurator.

With your details on quantities, mixtures, temperatures, additional functions and other information, we will prepare a customized quotation for you.

Service & Support for MIXACO Construction material mixers. You can rely on us and our experienced technicians.

More than mixers. Holistic customer care for over 55 years.

Test mixer free of charge and without obligation

Test our mixers in our test center – with your own raw materials, of course.

Learn More

Mix & Process Consulting

Have your mixing process checked by our mixing professionals – free of charge & no obligation.

Learn More

The MIXACO Technical Center

In our test centers we can optimize all parameters for your compound.

Learn MoreFor further information please do not hesitate to contact us.

Andreas Backhaus

Head of Sales

MIXACO

Dr. Herfeld GmbH & Co. KG

Niederheide 2

58809 Neuenrade

Germany

+49 (0)2392 9644-33

sales@mixaco.de