MIXACO Laboratory Container Mixer

Mixing batches from 6 liters. Ideal for product development and quality control.

Benefits at a glance. Perfect mixing of small batches.

- Various tool and motor combinations

- Flexible mixing in 6 or 12 liter containers

- Laboratory mixer for all common mixing processes

- Ideal for product development, research, quality assurance and small-scale production in all industries

- Scale-up from laboratory to production possible

- Mixing of small batches

- Extremely short mixing time from 3 minutes

- No product contamination due to closed mixing chamber

- Realistic simulation of production results

- Individual configuration of mixing tools

- Variant as laboratory heating mixer available

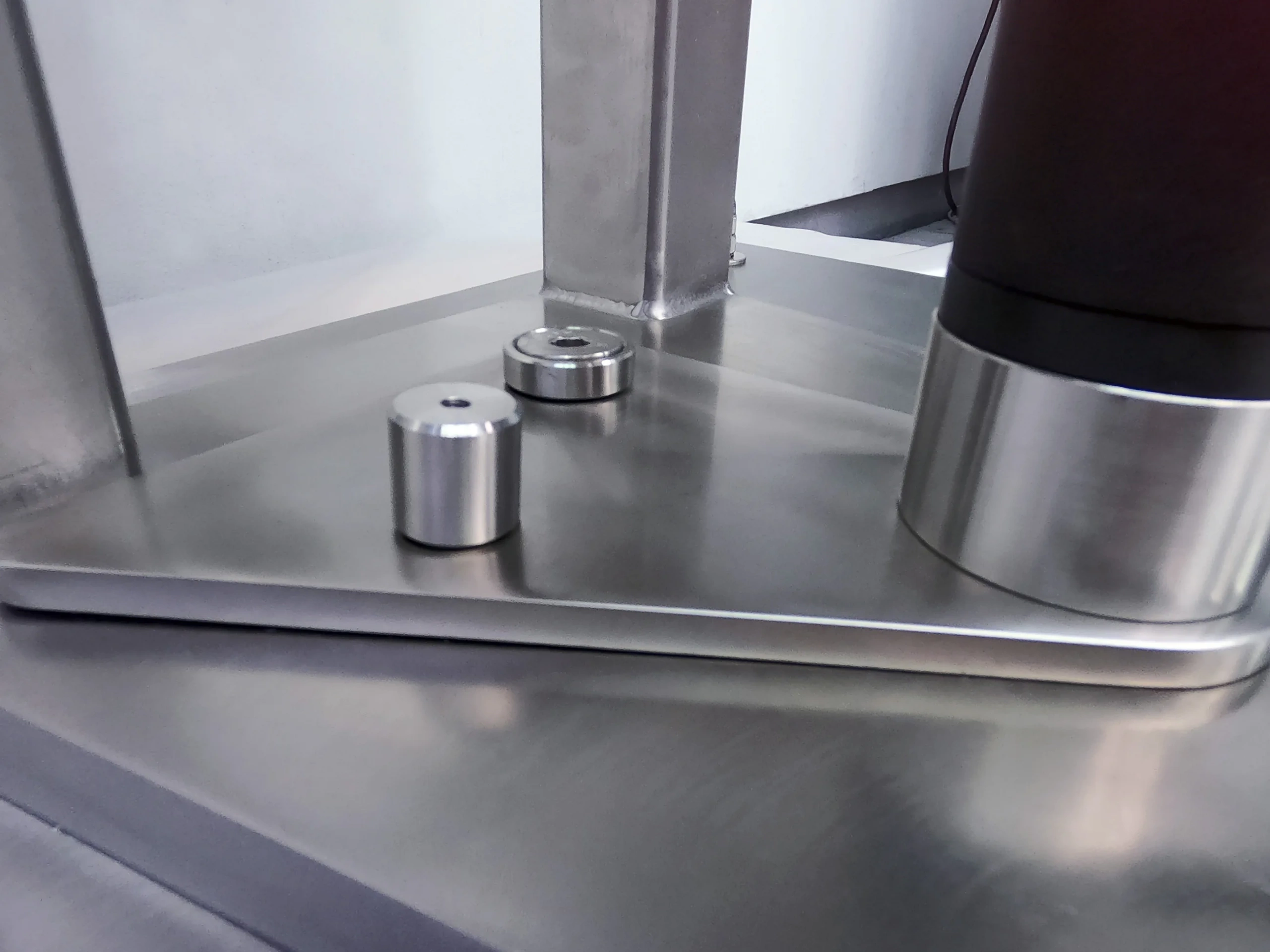

- Convenient exchange of mixing vessels and mixing tools

- Can be used for a wide variety of mixing tasks with many tool and motor combinations

- Laboratory mixer is not a tabletop unit, yet space-saving and easy to install via Plug & Play

- Low energy consumption

- Easy and fast cleaning

- Intuitive operation in manual or automatic mode

- Additional functions such as dedusting, injection, remote maintenance

- Innovative, web-based control with real-time visualization many mixing tasks

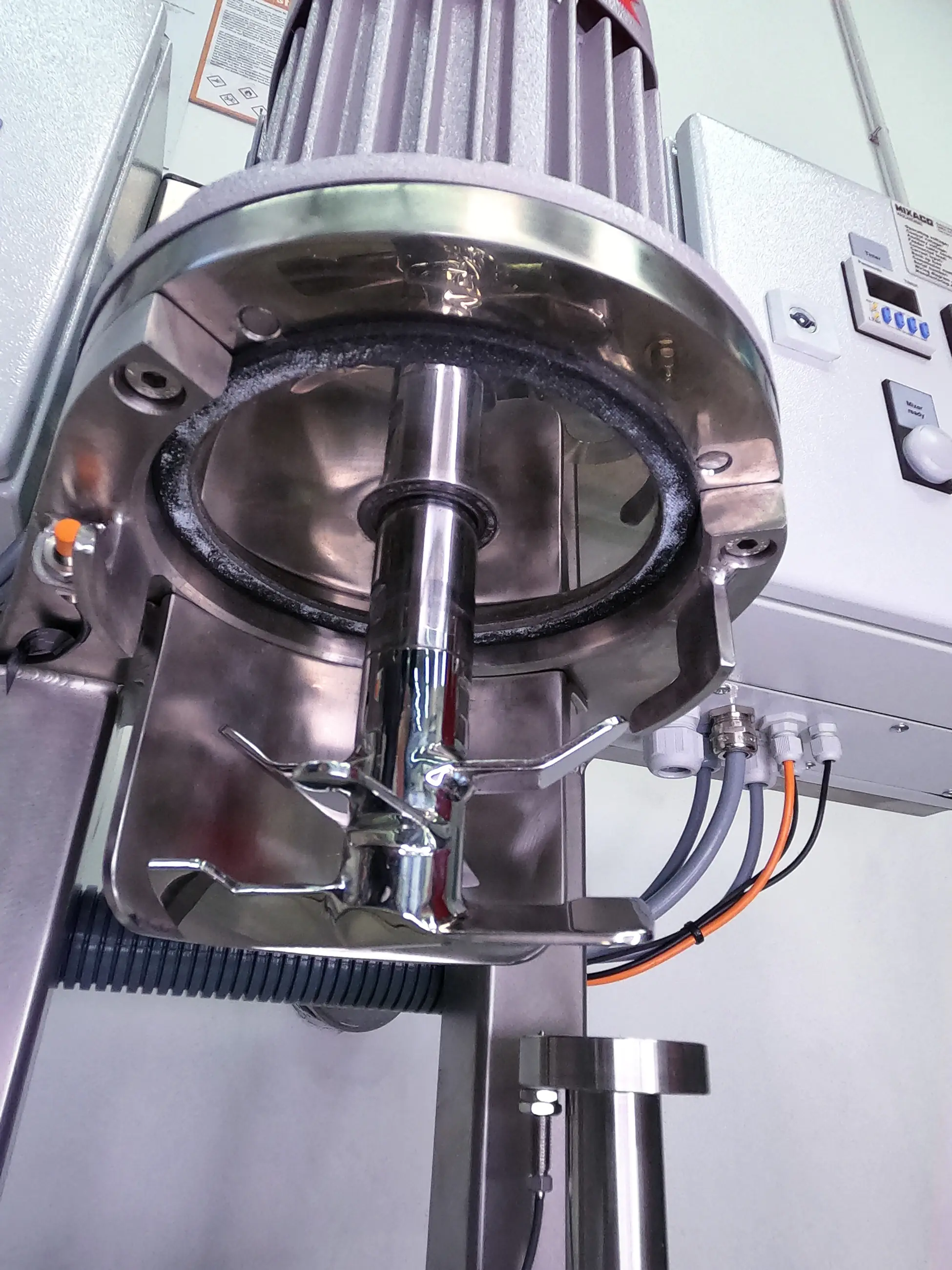

Functionality. Vortex principle in miniature.

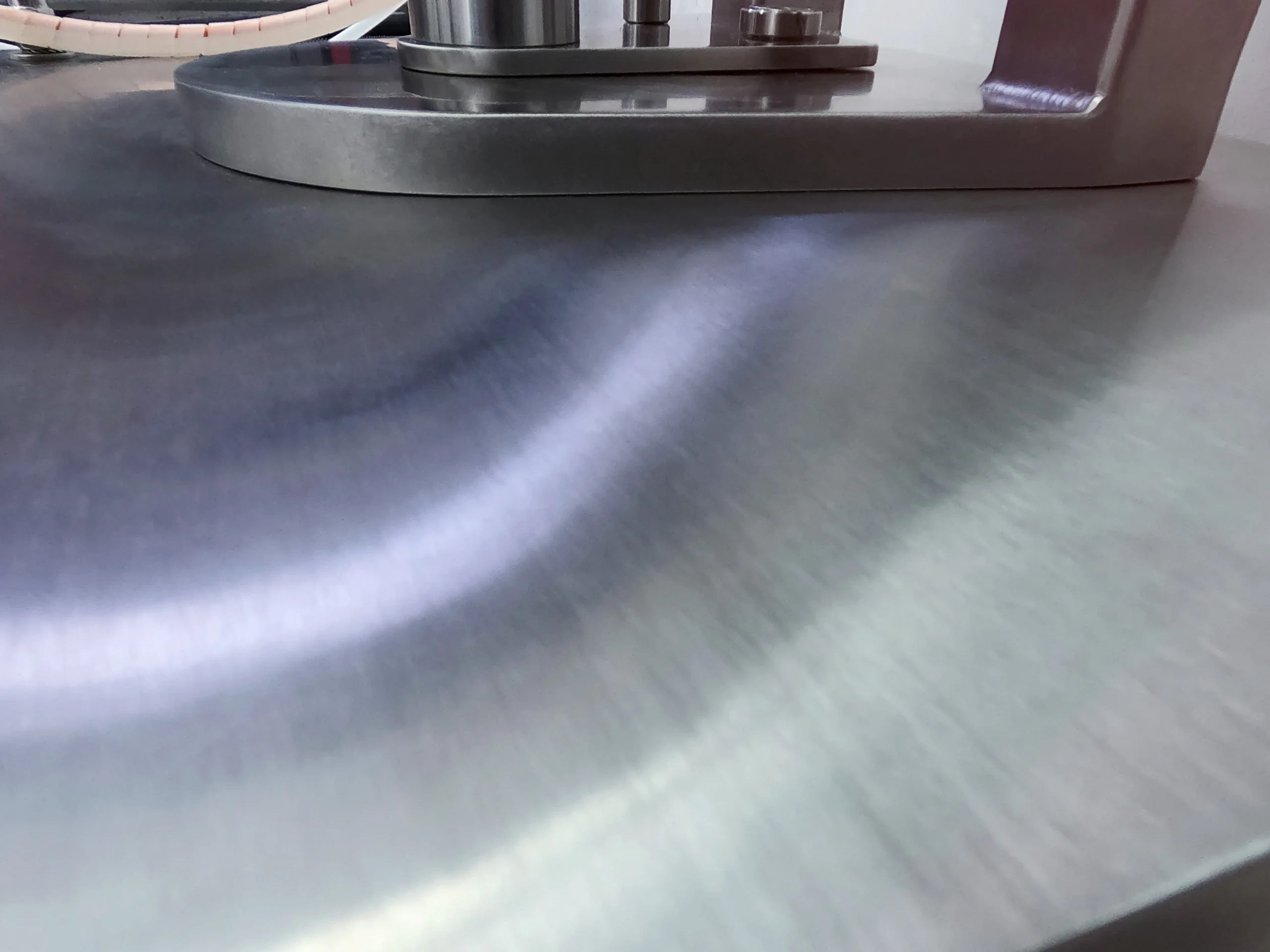

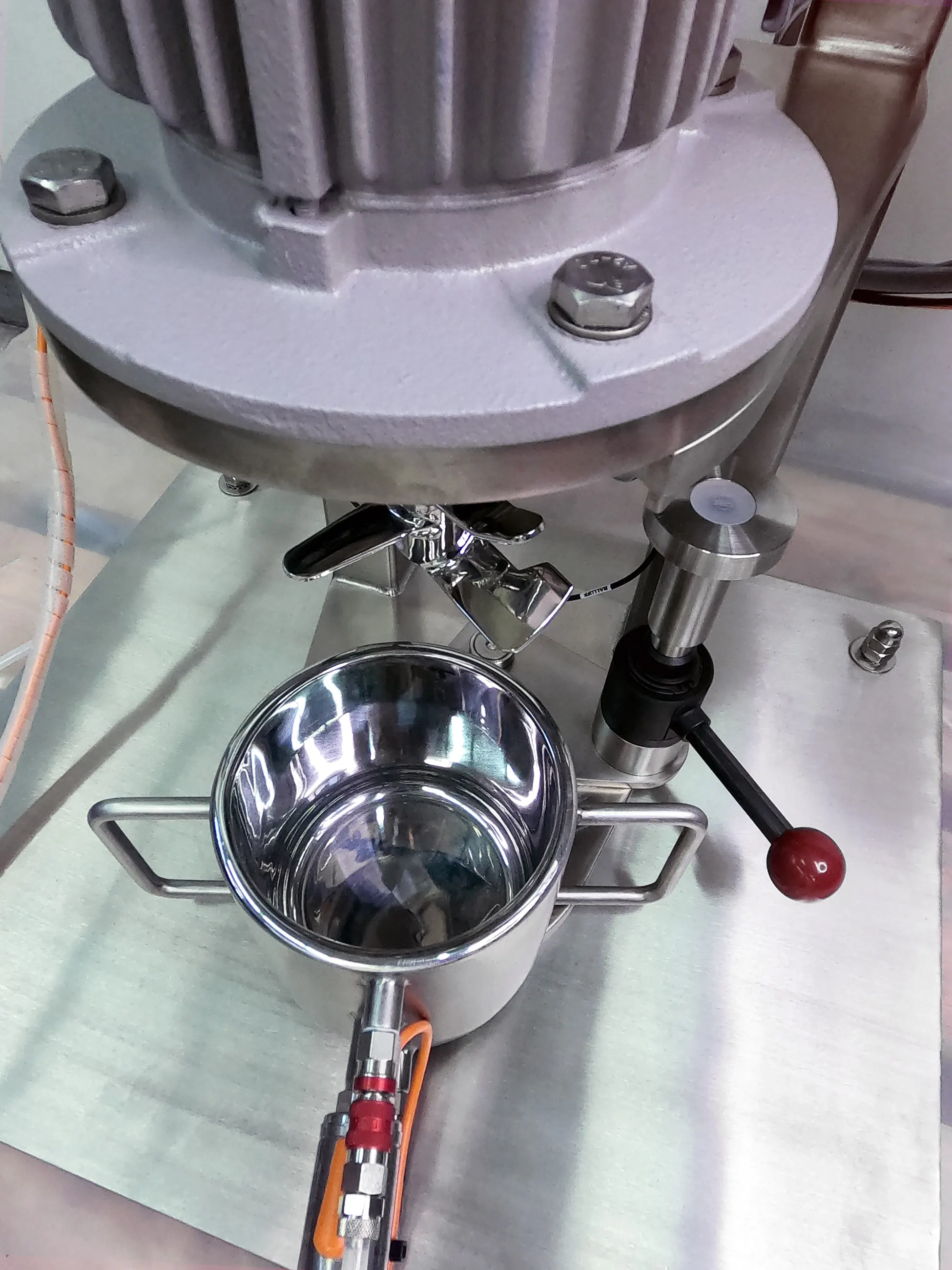

The MIXACO laboratory mixer works just like a large container mixer. However, in the case of the laboratory container mixer, the mixing container is only up to 12 liters in size and can be replaced quite easily by hand.

Our laboratory mixer in the container mixer version is a powerful and versatile mixer for shortening the path from product development to production readiness or for testing new formulations.

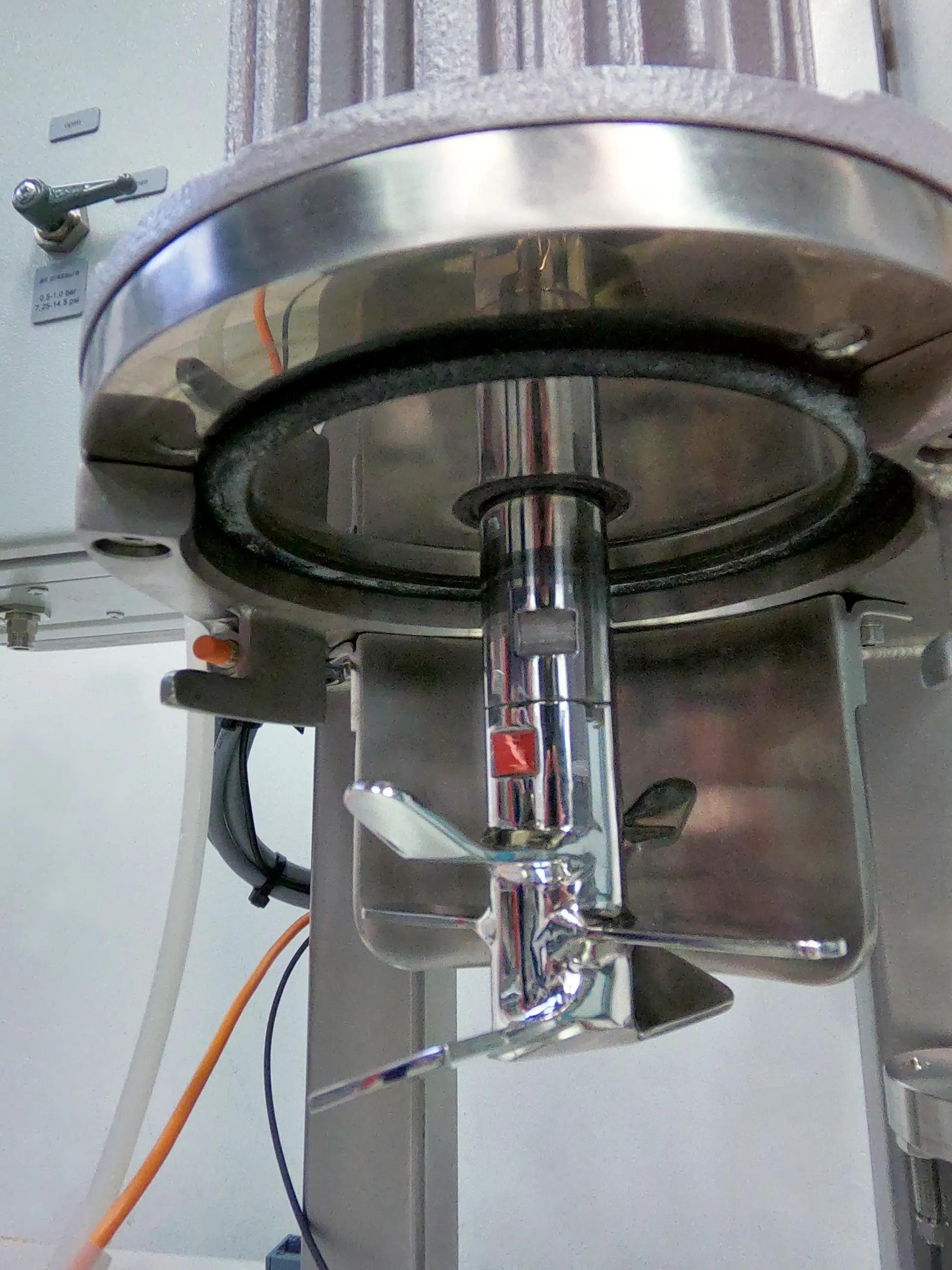

The container is fixed to the mixing head and turned upside down by 180° for the mixing process. The mixing material is transported upwards by the mixing tools in the container and sinks back down again by gravity. The result is perfect mixing without dead spaces.

Control. Safe, efficient and economic.

The control of the laboratory container mixer is based on a Siemens S7 PLC and meets today’s requirements for safety, efficiency and economy. The development and programming of the control system from a single source ensures optimum integration of the mixer components. Alternatively, it is also possible to use Allen-Bradley components (incl. Panelview operating unit).

The control can also be designed according to UL / NEMA. In addition, the control can be equipped with an interface for data exchange to a higher-level control.

Siemens TP700

The control can also be designed according to UL / NEMA. In addition, the control system can be equipped with a touch panel TP700 to create up to 99 mixing programs in tabular form, each with ten working steps. Data acquisition and storage of the measured values takes place. Comprehensive data acquisition on temperature, speed, active power, torque, moisture content and numerous other parameters is possible, which are visualized via the touch panel. be equipped for data exchange to a higher-level control system.

Allen Bradley

Control to UL / NEMA standards with an Allen Bradley PLC and Panelview control panel is also possible.

Mixing positions. Basic and mixing position in detail.

In the home position the mixer is loaded, the container is correctly positioned to the mixing head and secured for the lifting process.

As soon as the container together with the mixing head reaches the mixing position after a 180° swivel, the mixing process is started.

Mixing methods. Flexible mixing of various materials.

Our laboratory mixer is ideal for product development, trial mixing, quality assurance and small-scale production. Mix components with very different bulk densities, structures and sizes together. Even dusts and finest particles are optimally mixed. Break down agglomerates into primary particles. Liquids and gases can be added during mixing.

For mixing processes with heat supply, the stationary laboratory mixer can be designed as a heating mixer “HM LAB”. The mixture is precisely tempered via a double-walled design of the mixing vessel.

Realize a wide variety of coating processes, such as coating with liquid raw materials, which are subsequently re-solidified by controlled cooling on the particles.

- Homogenize

- Dispersing

- Agglomeration

- Deagglomeration

- Wetting

- Comminution

- Coating

- Digestion

- Fiber pulping and dyeing

- Absorbing

- Homogenization of bulk materials

- Improvement of product quality

- and much more

The perfect mixer for every laboratory.

The MIXACO laboratory mixer is suitable for mixing small quantities. These are needed for research and product development, quality assurance and for small-scale production in all industries.

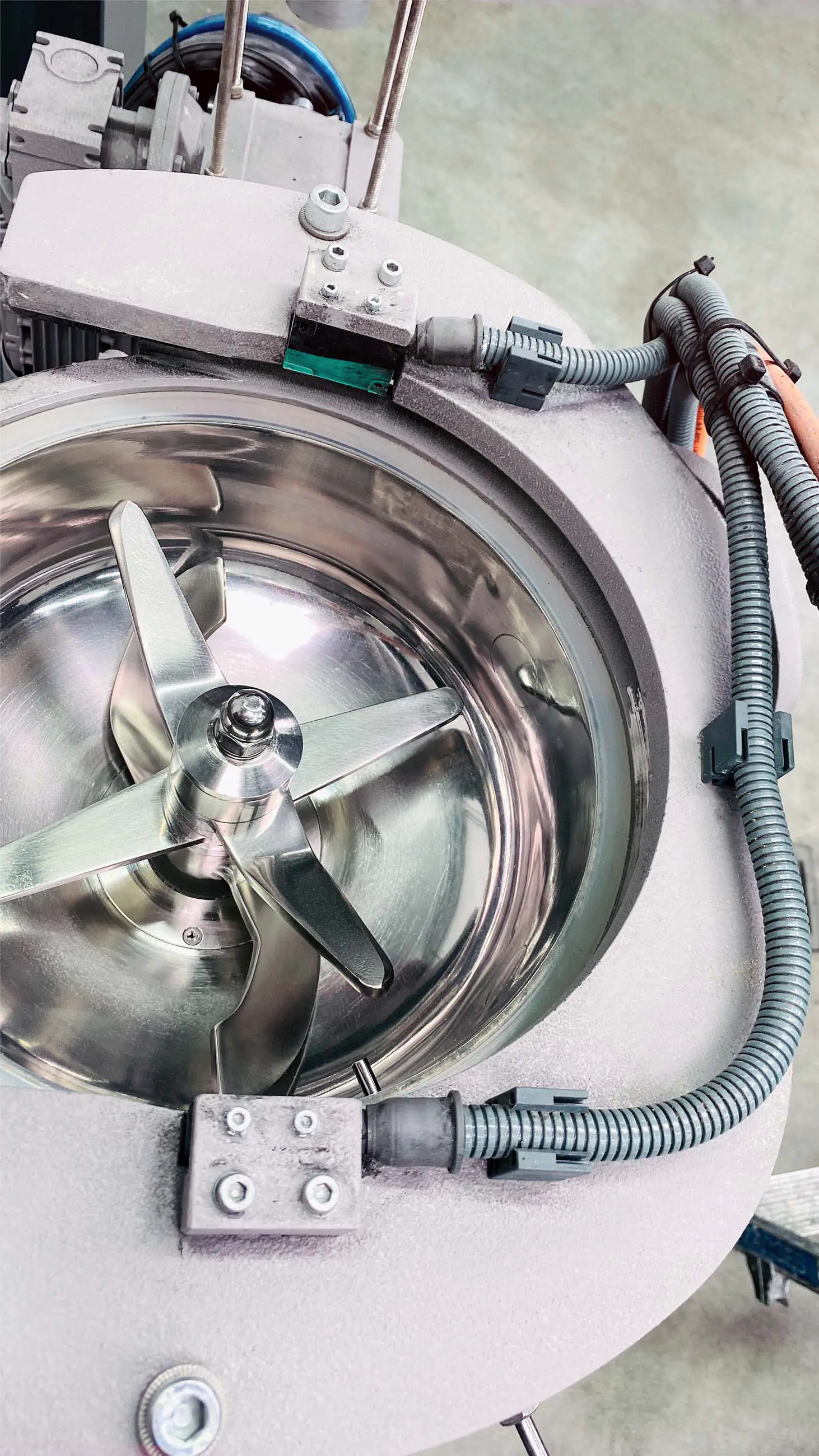

Mixing tools. Optimum mixing quality for small batches.

The different mixing tools of the laboratory container mixer make it a very versatile mixer that can be used in all industries.

Compared to small benchtop units, it offers the complete functionality of a large production mixer. The upscaling from laboratory to production is easy and reliable.

Benefits of the Vortex™ Tools

- proven mixing technology

- additional heating of the mixed material

- optimal homogenization

- suitable for many mixing materials

- Powder coating premixes, granules with granules, powder with powder, granules with powder

- 5-10 m/s

- Mixing of temperature-sensitive materials, e.g. PTFE premixes

- Mixing tool: 5-10 m/s, copper: ca. 40 m/s

- Color concentrates, masterbatch

- 25-40 m/s

- Color concentrates, masterbatch, toner, powder coating premixes

- 15-20 m/s

- PVC, masterbatches, SPC

- 20-40 m/s

Additional features. From ATEX to remote maintenance.

The MIXACO laboratory container mixer can be expanded in many ways. Additional adaptations can be developed in cooperation with our engineers according to your individual requirements. We will be happy to advise you on the possibilities:

- Design as laboratory heating mixer possible

- Dust extraction: suction device at the mixing head, which extracts the fine dust produced in the mixing vessel after the mixing process

- Temperature sensor in the mixing head to detect the product temperature during mixing. The temperature is displayed on the control panel

- Aeration and feeding during the mixing process

- Injection: A pneumatically operated device in the mixing head for the addition of liquid or gaseous substances – the design of the injection can be customized, e.g. longer / thinner

- Interchangeable mixing head system

- Data recording and evaluation

- Compatibility with existing plants and containers

- Extended stainless steel design of the container mixer

- Wear protection of the tools

- Hygienic design / WIP – CIP cleaning

- Special coating

- Coatings

- AGV (Automatic Guided Vehicle) compatibility

- ATEX/NEC design

- 360° cloud monitoring (MIXACO Control Center)

Lab Container Mixer sizes. We gladly advise you.

As the inventor of the container mixer, we at MIXACO are committed to innovation in industrial mixing technology.

Service & support for our mixers. You can rely on our experienced technicians.

Get quote for the perfect mixer in 2 minutes.

More than mixers. Holistic customer care for over 55 years.

Test mixer free of charge and without obligation

Test our mixers in our test center – with your own raw materials, of course.

Learn More

Mix & Process Consulting

Have your mixing process checked by our mixing professionals – free of charge & no obligation.

Learn More

The MIXACO Technical Center

In our test centers we can optimize all parameters for your compound.

Learn More