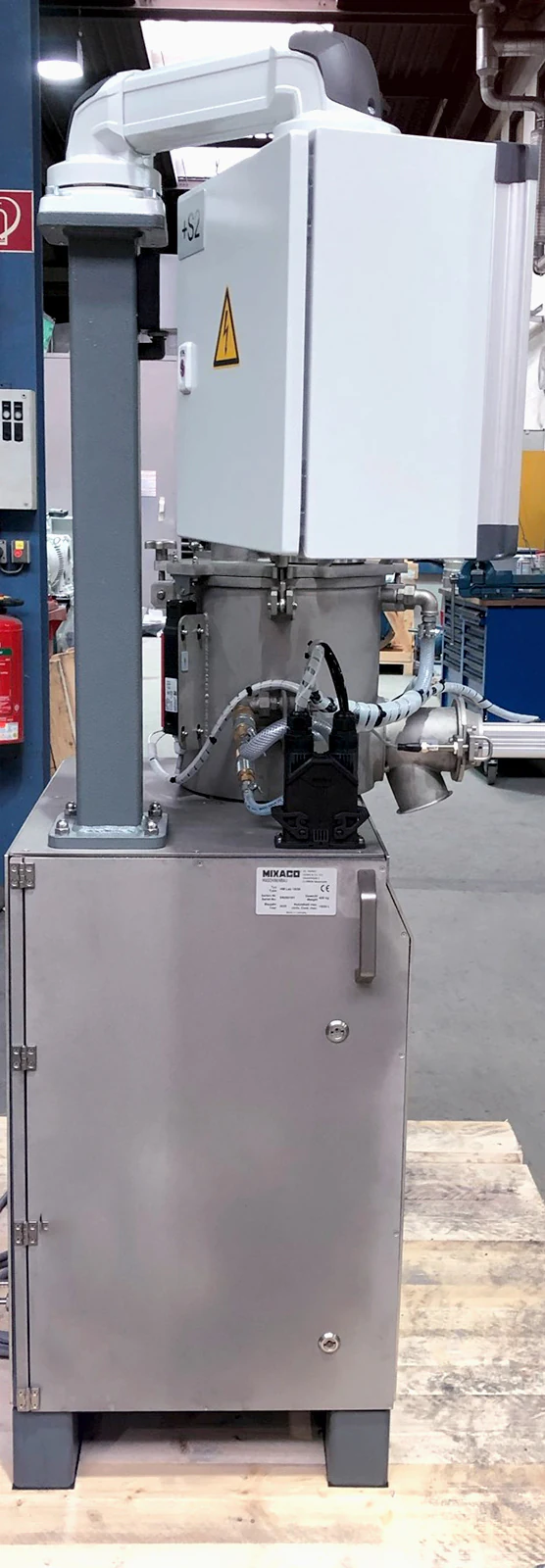

MIXACO Laboratory Heating Mixer Lab HM

The 3-in-1 Heating Mixer for Laboratories. 5, 10 and 20 Liter Volumes Fully Automatic Heating and Mixing.

Advantages at a Glance. One Mixer for 3 Container Sizes.

The MIXACO Lab HM mixer series is all about flexibility. The mixer base contains a high-performance motor that ensures the optimum peripheral speed and the corresponding torque for all sizes. A special highlight of the new MIXACO Lab HM are exchangeable vessels, which can be precisely replaced via a quick coupling system, depending on the desired batch size. 100% safety is guaranteed here.

- Flexible mixing in 3 container sizes 5, 10 and 20 liters

- Laboratory mixer for all common mixing processes

- Heating with total temperature control

- Fully automated processes

- Quick couplings for compressed air, tempering fluids, electrics

- Combination of flexibility and cost efficiency

- Standard lid connections: Inspection port, filter, additional inlet (depending on vessel size)

- Automated emptying of the double jacket of liquids

- Easy data export via CSV

- 7″ touch display

- 7.5 kW high performance motor

- Pneumatic discharge

- Ideal for product development, research, quality assurance and small production in all industries

- Direct scale-up from laboratory to production

- No product contamination due to closed mixing chamber

- Realistic simulation of production results

- Convenient exchange of mixing containers and mixing tools

- Can be used for a wide variety of mixing tasks with many tool and motor combinations

- Low energy consumption

- Easy and fast cleaning

- Intuitive operation in manual or automatic mode

- Additional functions such as dedusting, injection, remote maintenance

- Innovative, web-based control with real-time visualization

- Cloud-based monitoring (optional)

Operating Principle. Fast – Exchangable – Cost-efficient.

Specially designed mixing tools are provided for each container size. The tools can be individually configured, which allows the mixing intensity to be adjusted to your needs and guarantees optimum mixing performance.

The standardized double jacket tanks are equipped with a quick separation of the supply and return lines for cooling liquids, in order to be able to guarantee complete control over temperature and mixing quality at any time.

Mixer Control System. Safe, Efficient and Economical.

The control of the Universal Mixer Revolution™ is based on a Siemens S7 PLC and meets today’s requirements for safety, efficiency and economy. The development and programming of the control system from a single source ensures optimum integration of the mixer components. Alternatively, it is also possible to use Allen-Bradley components (incl. Panelview operating unit).

The control can also be executed according to UL / NEMA. In addition, the control can be equipped with an interface for data exchange to a higher-level control.

Siemens TP700

Up to 99 mixing programs, each with ten working steps, can be created in tabular form via the TP700 touch control panel. Data acquisition and storage of the measured values takes place. Comprehensive data acquisition on temperature, speed, active power, torque, moisture content and numerous other parameters is possible, which are visualized via the touch panel.

Allen Bradley

Control to UL / NEMA standards with an Allen Bradley PLC and Panelview control panel is also possible.

Mixing Techniques. Mixing with Full Temperature Control.

With the MIXACO Lab HM heated mixer, common heating mixing processes are possible. For your raw materials and mixing tasks, the mixing tools and mixing parameters can be individually adjusted to achieve an optimal mixing result. The MIXACO heating lab mixer performs the following tasks with ease:

- Homogenize

- Dispersing

- Agglomeration

- Deagglomeration

- Wetting

- Coating

- Disintegration

- Disintegration and dyeing of fibers

- Absorbing

- Homogenization of bulk materials

- Improvement of product quality

- And much more

The all-in-one Heating Mixer for Your Lab.

The MIXACO Lab HM laboratory heating mixer is the all-in-one solution for all mixing processes in the laboratory. The additional heating function makes it even more flexible.

Mixing Tools. Optimal Mixing Quality for Small Batches.

Specially designed mixing tools are provided for each container size. The tools can be individually configured, which allows the mixing intensity to be adjusted to your needs and guarantees optimum mixing performance.

Advantages of Vortex™ Mixing Tools

- Proven mixing technology

- Additional heating of the mixed material

- Optimal homogenization

- Suitable for many mixing materials

- PVC, Masterbatch, SPC

- 20-40 m/s

Mixer Options. From ATEX to Cooling Function.

The laboratory heating mixer can be expanded in many ways. Additional adaptations can be developed in cooperation with our engineers according to your individual requirements. We will be happy to advise you on the possibilities:

- 2-stage mixing tools for gentle vortex homogenization

- 3-stage mixing tools for intensive vortex homogenization

- 4-stage mixing tools for high-friction vortex homogenization

- Wear-resistant mixing tools

- Nozzle for liquid injection

- Hopper for manual or automatic filling

- Laboratory cooling mixer KM in the appropriate size

- Ventilation and feeding during the mixing process

- Injection: A pneumatically operated device in the mixing head for the addition of liquid or gaseous substances – the execution of the injection can be adapted to customer-specific requirements, e.g. longer / thinner

- Exchange mixing head system

- Data recording and evaluation

- Compatibility with existing plants and containers

- Extended stainless steel execution of the container mixer

- Wear protection of the tools

- Hygienic execution / WIP – CIP cleaning

- Special coating

- Coatings

- AGV (Automatic Guided Vehicle) compatibility

- ATEX/NEC execution

- Remote maintenance

- 360° cloud monitoring (MIXACO Control Center)

As the inventor of the container mixer, we at MIXACO are committed to innovation in the industrial mixing technology.

Service & Support. Rely on our experienced technicians.

Mixer Quotation Configurator: Just 2 minutes to the perfect mixer for your raw materials.

Simply tell us your requirements and we will recommend you the optimum mixer for your raw materials and applications. Use our configurator.

With your details on quantities, mixtures, temperatures, additional functions and other information, we will prepare a customized quotation for you.

More than mixers. Holistic customer care for over 55 years.

Test mixer free of charge and without obligation

Test our mixers in our test center – with your own raw materials, of course.

Learn More

Mix & Process Consulting

Have your mixing process checked by our mixing professionals – free of charge & no obligation.

Learn More

The MIXACO Technical Center

In our test centers we can optimize all parameters for your compound.

Learn More