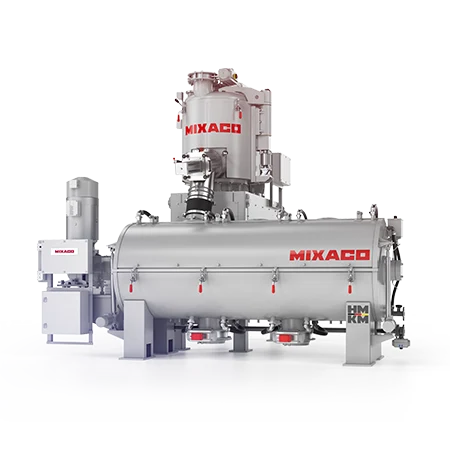

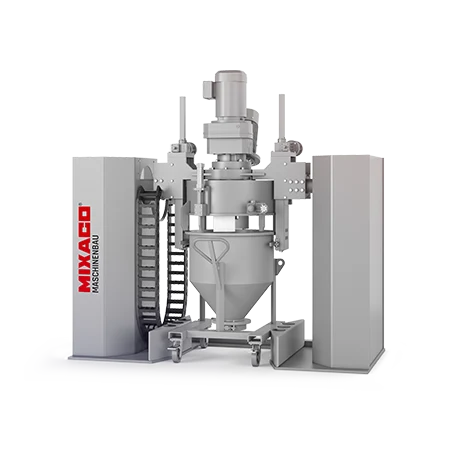

Dry Mixer

Mix all dry materials and powders perfectly. Custom Made Dry Mixer.

Advantages of the MIXACO Dry Mixers

MIXACO Dry Mixer – also for your solid raw materials.

Advantages of our Dry Mixers: perfectly mix all dry solids.

Our dry mixers mix and process virtually all dry substances and powders from a wide range of industries. Our mixer assortment ranges from laboratory mixers with 5 liter mixing volume to stationary mixers for sizes up to 10,000 liters.

We have the perfect dry mixer for every application that can be seamlessly integrated into your existing processes.

Due to the flexible combination of mixing tools, mixing speeds, machine sizes, motors and additional options, our dry mixers are perfectly adapted to your raw materials and requirements. In addition to heating / cooling, dedusting, injection of liquids / gases, the additional options also include cost-effective remote maintenance and connection to the innovative MIXACO Control Center – a web-based real-time monitoring of all mixing parameters by means of a digital twin.

Due to our more than 50 years of experience in industrial mixing as well as the innovative and patented mixing processes, we guarantee the highest mixing quality. All types of powder as well as dry materials in the form of granules, flakes, pellets or dust are optimally processed. Even mixing of the most sensitive substances is possible without breakage, wear, dust formation, static charging and without temperature increase.

Convince yourself of the advantages of our dry mixers for solids and powders:

- Excellent homogeneity with maximum product protection

- Short mixing times: perfect mixing in only 2 – 6 minutes

- Intensive & fast mixing of dry materials

- Slow & gentle dry mixing of sensitive materials

- 100% uniform homogenization of dry materials with liquids

- Quick and easy cleaning

- Low energy consumption

- Vertical or horizontal dry mixers

- Cost-saving use-dependent maintenance / remote maintenance

- Special surfaces for food products

- Dry mixers with heating & cooling function

- One mixer for different applications: Mixing, moistening, flavoring, coating, melting, etc.

- Small laboratory dry mixers for 5-20 liters – for product development, quality control & small batches

- Dry mixers for large batches up to 10,000 liters

- Batch tracing possible

- Variable filling level

- No dead spaces or cavities in the interior of the mixer

- No product contamination due to closed mixing chamber

- Consistent mixing quality even with challenging dry materials

- Gentle mixing of fragile powders (e.g. filigree effect pigments) without breakage or dust formation

- Mixing tools easily accessible and demountable

- Proven, low-maintenance machine technology “Made in Germany” for minimum downtime and high availability of the production plant

- Dry mixers in ATEX execution

- Real-time monitoring of dry mixers via the MIXACO Control Center (MCC) (cloud monitoring)

Mixer Quotation Configurator: Just 2 minutes to the perfect mixer for your raw materials.

Simply tell us your requirements and we will recommend you the optimum mixer for your raw materials and applications. Use our configurator.

With your details on quantities, mixtures, temperatures, additional functions and other information, we will prepare a customized quotation for you.

Dry mixers for countless raw materials and industries. In different mixer sizes.

Our mixers are specially designed for mixing dry materials and powders. MIXACO dry mixers are ideal for the production of a wide variety of products in the fields of food, chemicals, plastics, PVC, building materials, pet food, pharmaceuticals and cosmetics, for example:

- Food like aroma, sugar, cereal, drink powder, milk powder, flour, instant powder, tea, spices, herbs, vitamin powder etc.

- Plastic granules for the production of PVC, ABS, PS, POM, PE, PP, PTFE etc.

- Color powders, pigments and powder coating

- Masterbatches, color masterbatches

- Detergent powder / granules

- Ceramic powders (gentle processing without damaging the mixed material and easy application of liquids)

- Battery powders (100% purity and no contamination with metal powders due to abrasion)

- Silicates (guarantee of absorption and adsorption enables wear-free processing)

- Metal powders and granules (wear-resistant processing with good explosion suppression)

- Artificial fertilizers (fracture-resistant processing with coating possibility)

- Powder for cosmetics (make-up, eye shadow, lipstick, rouge, etc.)

- Animal food & feed

- Fertilizers, insecticides, pesticides, herbicides

- Powder metallurgy and fine ceramics

- Plastic powders for 3D printers

- Powder emulsifiers

- Dry mixes for mortar, plaster, concrete, screed, plaster, cement

- Powders for fire extinguishers and fire retardant products

- And many more

Mixing Process. Dry Mixer with Various Mixing Processes.

Dry mixers from MIXACO offer a very wide range of mixing processes and mixing tools, which are individually optimized and configured for the different dry materials and powders.

Examples of mixing processes and applications for dry raw materials:

- Homogenization of bulk materials

- Homogenization of dry materials with liquids

- Injection of liquids

- Injection of gaseous substances

- Mixing under vacuum

- Dust-free mixing

- Heating and / or cooling

- Crushing

- Drying

- Moistening

- Agglomeration

- Intensive deagglomeration

- Slow and gentle homogenization

- Fast and intensive mixing

- Coating

- Wetting of particles

- Change of product properties

- etc.

Options. Dry mixer perfectly tailored to your raw materials.

With the help of numerous additional functions, our dry mixers can be perfectly adapted to any raw material and application. Apart from the following options, we as a manufacturer can of course also implement completely individual requirements.

Individualize your dry mixer e.g. with the following additional functions:

- Dust removal / dust-free mixing

- Temperature measurement

- Integrated weighing

- Additional outlet spouts

- Sample removal during the mixing process

- Ventilation and feeding during the mixing process

- Dosing / spraying / injection of liquids and gases during the mixing process

- Mixing head cooling / cooled mixing tools

- Heating / cooling function

- Hydraulic tool stroke

- Lifting swivel cover (container mixer)

- Water cooled motor

- ATEX executions

- Data recording and evaluation

- Remote maintenance

- Hygienic design / surfaces for food

- Abrasion resistant mixing vessels and tools

- etc.

As the inventor of the container mixer, we at MIXACO are committed to innovation in the industrial mixing technology.

FAQ. Dry Mixer Knowledge.

A dry mixer is a mixer for dry substances and powders. The main function of dry mixers is to produce mixtures that are as homogeneous as possible. In contrast, the focus of a “wet mixer” is on decomposition and new composition of substances.

Dry mixers are largely used in industry for high throughput and product premixing.

Industrial dry mixers are required in various industries for the production of numerous products, for example, food, pet food, chemicals, plastics, building materials, pharmaceuticals, cosmetics or rubber.

Although a dry mixer predominantly mixes dry, dry substances are often to be mixed with liquids or coated during mixing. Since this application is frequently used in addition to pure dry mixing, conventional dry mixers can actually also always mix “moist”. One could therefore say that a dry mixer is also a wet mixer if required and if the technical design is correct.

The dry part of the mixture usually predominates, which is why the term dry mixer has become established for this type of mixer. It also makes it easier to distinguish dry mixers from fluid mixers, which specialize in mixing liquids.

Dry mixing is primarily “only” about homogenization and not about material reactions, the mixing time is rather short compared to the fluid mixer. MIXACO dry mixers can produce perfect homogeneity in as little as 3 minutes – depending, of course, on the raw materials, their bulk density and the material concentration.

Dry mixers can be differentiated according to various designs, functions and mixing tools, each suitable for specific raw materials and applications.

According to design, cone mixers, double cone mixers, V-mixers or drum mixers can be distinguished. In addition, there are vertical or horizontal dry mixers. Container mixers can have different designs as long as the mixing container is exchangeable.

A belt or paddle dry mixer gets its name due to the shape of the tool, here the raw materials are mixed with the help of a belt or paddle.

Based on the basic mode of operation, a distinction can be made between continuous dry mixers and discontinuous dry mixers or batch dry mixers.

The term “dry mixer” is therefore not really firmly defined. It basically only says that a dry mixer is designed primarily for mixing dry substances and powders, and thus includes different mixer models.

Which is the optimal dry mixer for your raw materials depends on various aspects:

- Type of raw materials – fine or chunky

- Density & volume of raw materials

- Raw materials / powders free flowing or sticky

- Mixing of different particle sizes and textures

- Fragile materials

- Quality of final products

- Temperature sensitive dry materials

- Size, shape and moisture content of the powder particles to be mixed

- Production equipment

- Integration into production processes

- Mixing accuracy

- Approved materials of construction

- Energy consumption

- Throughput

- etc.

The desired applications and mixing processes also influence the choice of the right dry mixer:

- Homogenize

- Coating

- Injecting liquids or gases

- Agglomerate

- Deagglomeration

- Dispersing

- Vacuum drying

- Humidification

- etc.

Hygiene and safety aspects also play a role in the choice of dry mixer:

- Prevent cross contamination

- Food safe surfaces

- Cleaning of the dry mixer between batches

- Fast drying

- Cleaning according to food hygiene

- Dust-free mixing possible

- Explosion-proof mixing according to Atex necessary

- Real-time monitoring of mixing processes

- Simple & safe operation

- etc.

Service & Support for MIXACO Dry Mixer. You can rely on us and our experienced technicians.

More than mixers. Holistic customer care for over 55 years.

Test mixer free of charge and without obligation

Test our mixers in our test center – with your own raw materials, of course.

Learn More

Mix & Process Consulting

Have your mixing process checked by our mixing professionals – free of charge & no obligation.

Learn More

The MIXACO Technical Center

In our test centers we can optimize all parameters for your compound.

Learn MoreFor further Information just get in contact with us.

Markus Frantzen

General Manager MIXACO USA

MIXACO USA LLC

1784 Poplar Drive

Greer, SC 29651

+1 (0)864 331-2320

+1 (0)864 331-2321

info@mixaco.com