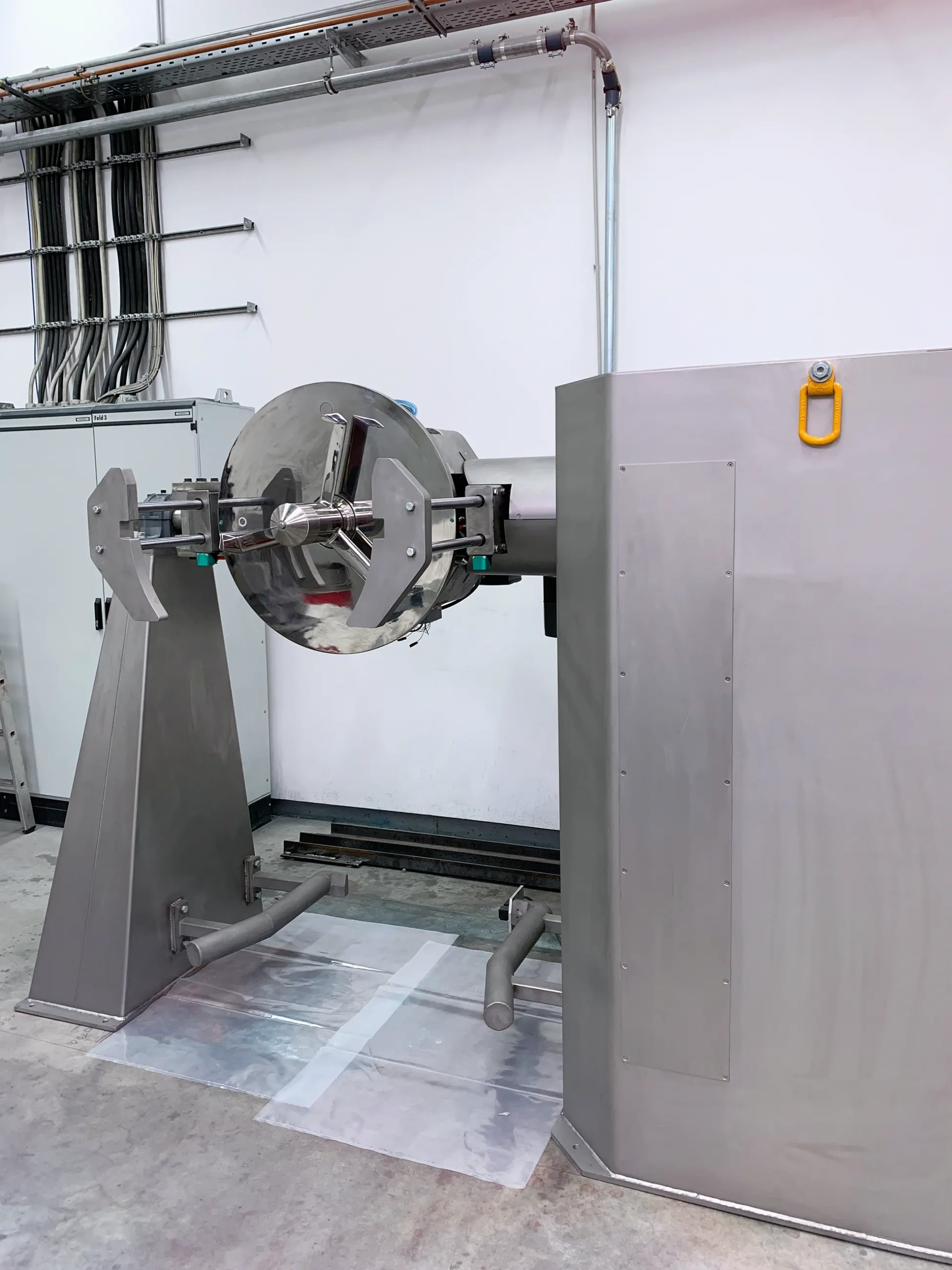

MIXACO Container Mixer CM i4

The new Industry 4.0 container mixer CM i4. Innovative machine components ideally suited for frequent recipe changes due to reduced cleaning times.

Benefits at a glance. The flexible Container Mixer CM i4.

The innovative, ultra-flat mixing head reduces cleaning.

The flat mixing head has a smaller surface compared to a conventional mixing head and can therefore be cleaned more quickly and easily. The large distance between the mixing tool and the mixing head enables cleaning in the installed state. This makes extremely fast cleaning cycles and recipe changes possible. The new tool design ensures optimum mixing stream formation (vortex) with moderate temperature input.

By saving the bottom plate, additional cleaning effort is reduced.

The dustprotected installation of many machine components in the right-hand side of the stand also reduces cleaning requirements.

Optimized extraction by means of a special dedusting device on the mixing head, which sucks off the fine dust produced in the mixing vessel after the mixing process.

The container mixer can be designed for operation of explosive applications according to customer specification in ATEX categories.

Temperature sensor in the mixing head for recording the product temperature during mixing. The temperature is displayed on the control panel.

The container mixer CM i4 fleX offers the possibility to use three different container sizes in one mixer. This allows a larger batch range to be covered.

- higher flexibility in production

- lower investment volume

- higher efficiency of the mixers due to better capacity utilization

- flexible batch sizes and recipe changes

- seals are attached to the mixing container

Moderate circumferential speeds of 4 – 15 m / s reduce product buildup.

The container mixer CM i4 can be used for a wide variety of mixing tasks with many motor combinations. The mixing technology, components and accessories can be flexibly and individually adapted to customer requirements.

Functionality. A head start through innovative mixing technology.

As the inventor of the container mixer, we at MIXACO feel committed to innovation in industrial mixing technology. With the new container mixer CM i4, we are once again taking a big step forward into the future of industrial mixing.

The container mixer CM i4 is a further development of the proven container mixer concept. However, the CM i4 has new features that make the container mixer even more attractive.

In contrast to the Multitool container mixer, it has a completely new type of flat mixing head, which offers significant advantages for cleaning. The mixing tools do not have to be removed for cleaning. The design of the container mixer without a base plate also significantly reduces the cleaning effort.

The CM i4 is therefore particularly suitable for applications in which different recipes require frequent cleaning of the mixer. The additional efficiency is an important cost reduction factor in your production.

The CM i4 can be used for operation over several floors in your production thanks to its mobile containers and accessories, just like the container mixer Multitool and container mixer Vortex. Via appropriate connections, the mixing container can be emptied dust-free directly into extruders, kneaders, secondary vessels, weighing and bagging devices in the next process step.

With its revolutionary mixing system, the MIXACO container mixer CM i4 opens up versatile application possibilities for the production of numerous products. Another option is the use of multiple different container sizes with one mixer.

Industry 4.0 / IoT (Internet of Things)

This mixer represents the features of Industry 4.0 / IoT (Internet of Things) used in the mixing industry. Excellent mixing flexibility, high quality and cleaning effort reduced to a minimum are its distinguishing features. Equipped with the MIXACO Control Center (MCC), we set another milestone for highly efficient mixing plants. The MIXACO Control Center is available via web browser and provides, among other things, an overview of your mixer park.

Control System. Safe, efficient and economical.

The control of the container mixer CM i4 is based on a Siemens S7 PLC and meets today’s requirements for safety, efficiency and economy. The development and programming of the control system from a single source ensures optimum integration of the mixer components. Alternatively, it is also possible to use Allen-Bradley components (incl. Panelview operating unit).

The control can also be designed according to UL / NEMA. In addition, the control can be equipped with an interface for data exchange to a higher-level control.

Siemens TP700

Up to 99 mixing programs with ten work steps each can be created in tabular form via the TP700 touch control panel. Data acquisition and storage of the measured values takes place.

Allen Bradley

Control to UL / NEMA standards with an Allen Bradley PLC and Panelview control panel.

Mixing positions. Basic, mixing and cleaning position in detail.

In the basic position, the mixing head is oriented downwards and is loaded with a container containing the raw materials. The container is automatically positioned correctly and lifted to the mixing head via the container lifting device. Container and mixing head now form the mixing chamber.

The swiveling process is performed via the motorized swiveling device into the mixing position (180°). The mixing container is upside down after the swiveling process, the raw materials fall onto the mixing tools.

As soon as the mixing position is reached, the mixing process can be started, the mixing tools begin to rotate.

In the special cleaning position, the mixing head can be cleaned quickly and easily – without having to remove the mixing tool.

Mixing methods. Various mixing techniques can be used.

The container mixer CM i4 is used in a wide variety of applications, for example in powder coatings, in masterbatches, in the preparation of toner, color concentrates or additives.

With its revolutionary mixing system, the MIXACO container mixer CM i4 opens up versatile application possibilities for the manufacture of numerous products.

Another option is to use multiple container sizes with one mixer to allow different batch sizes with only one machine.

- Homogenize

- Dispersing

- Wetting

- etc.

The most flexible container mixer available.

Our CM i4 industrial mixer offers all the functions and mixing processes of our proven container mixer concept. Temperature-reduced mixing is also possible with the CM i4.

The novel mixing system of the MIXACO container mixer CM i4 enables the processing of countless raw materials from a wide range of industries:

Innovative mixing tools. Designed for mixers with flat mixing head.

The MIXACO mixing tool i4 was specially developed for use in a mixer with a flat mixing head. The innovative design of the i4 tool enables good mixing stream formation, even at moderate peripheral speeds. These amount to 4 to 15 m/s, depending on the application. Excellent homogenization and color application are guaranteed.

Due to the large distance to the mixing head base, the mold can be cleaned while installed. The large distance to the mixing head and also to the container as well as the innovative geometry of the i4 mold minimize material caking, which also significantly simplifies cleaning.

The advantages of the new i4 tool

- short mixing times with excellent homogenization of the material

- moderate temperature entry due to low circumferential speeds (4 – 15m/s)

- minimal product adhesion due to innovative geometry and large distances to mixing head and container

- cleaning of the mold and mixing head can be done with the mold in place

Additional features. From ATEX to remote maintenance.

The MIXACO container mixer CM i4 can be expanded in many ways. Additional adaptations can be developed in cooperation with our engineers according to your individual requirements. We will be happy to advise you on the possibilities:

- Suction device

- Temperature measurement of the mixed material

- Aeration and feeding during the mixing process

- Dosing of liquids and gases during the mixing process

- Data recording and evaluation

- Remote maintenance

- Compatibility with existing plants and containers

- Advanced stainless steel design of the container mixer

- Wear protection of the tools

- Addition possibility in mixing position

- Special coating

- Coatings

- AGV (Automatic Guided Vehicle) compatibility

- ATEX/NEC design

- 360° cloud monitoring (MIXACO Control Center)

i4 construction sizes. We will gladly advise you.

| Sizes | Usable Volume Liter | Batch Size kg | Mixing Time min/Batch |

|---|---|---|---|

| CM 50 | 40 | 20 | 3-6 |

| CM 150 | 120 | 60 | 3-6 |

| CM 300 | 240 | 120 | 3-6 |

| CM 150/300 | 120/240 | 60/120 | 3-6 |

| CM 450 | 360 | 180 | 3-6 |

| CM 600 | 480 | 240 | 3-6 |

| CM 300/450/600 | 240/360/480 | 120/180/240 | 3-6 |

| CM 800 | 640 | 320 | 3-6 |

| CM 1000 | 800 | 400 | 3-6 |

| CM 1300 | 1040 | 520 | 3-6 |

| CM 800/1000/1300 | 640/800/1040 | 320/400/520 | 3-6 |

| CM 2000 | 1600 | 800 | 3-6 |

| CM 1000/1300/2000 | 800/1040/1600 | 400/520/800 | 3-6 |

Parameter

Bulk density: 0.5 kg/l

Filling level: max. 80%

Charging: manually

Ask us for other sizes.

As the inventor of the container mixer, we at MIXACO are committed to innovation in industrial mixing technology.

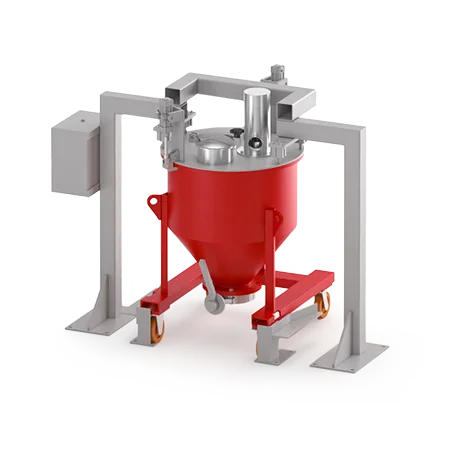

Container Mixer Accessories. For efficient Workflows.

Discharge Stations

Dust-free discharge of the mixed material into downstream further processing steps.

Learn More

Service & support for our mixers. You can rely on our experienced technicians.

Mixer Quotation Configurator: Just 2 minutes to the perfect mixer for your raw materials.

Simply tell us your requirements and we will recommend you the optimum mixer for your raw materials and applications. Use our configurator.

With your details on quantities, mixtures, temperatures, additional functions and other information, we will prepare a customized quotation for you.

More than mixers. Holistic customer care for over 55 years.

Test mixer free of charge and without obligation

Test our mixers in our test center – with your own raw materials, of course.

Learn More

Mix & Process Consulting

Have your mixing process checked by our mixing professionals – free of charge & no obligation.

Learn More

The MIXACO Technical Center

In our test centers we can optimize all parameters for your compound.

Learn More