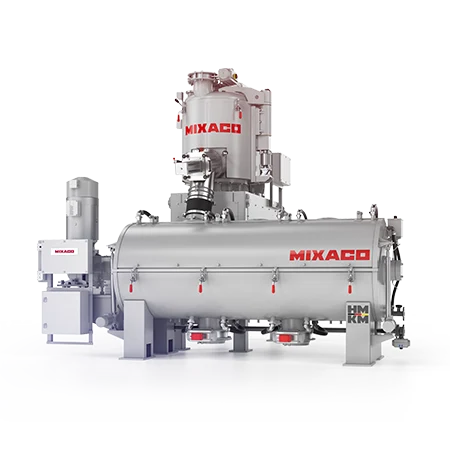

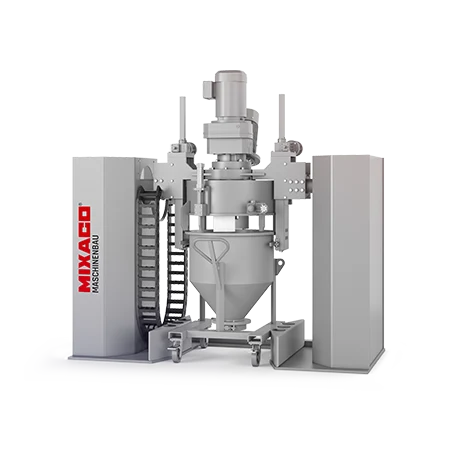

Industrial Mixer for Rubbers

One mixer for over 400 rubber compounds. Mix complex rubber formulations perfectly.

Stationary mixers and container mixers. Mix rubber perfectly.

The production of elastomers requires high precision in handling the mixed materials.

Due to the different material properties of the individual components, the mixing processes are often very complex.

General advantages of MIXACO industrial mixers

- High availability due to solid and proven machine technology

- Low idle times due to quick and easy cleaning

- High mixing quality due to optimal handling of the material

- Low energy consumption due to innovative designs and tools

- Optimal application solutions through customized tests and mixing procedures

- High flexibility through optimized handling of machines and containers

- High product variety due to wide range of machines for all batch sizes

- Easy operation due to innovative machine concept

- Reduction of the product defect rate

Advantages especially for rubber production

- Mixing of numerous small quantities of chemicals for rubber masterbatches

- Homogeneous, stabilized & dust-free premixes – without plastic bags

- No bag filling machine required and residue-free downstream processing

- No overdosing in fine powder blends due to stabilized particles (coating, bonding, agglomeration)

- Mix more than 100 different rubber raw materials in one mixing room

- Produce more than 400 different rubber compounds

- Maximum flexibility for a wide range of different materials

- Highest precision even for enormously complex formulations

- Batch tracking

- Reproducibility and consistent quality for reliable downstream processing

- High-precision metering of chemicals and liquids through innovative technologies

- Reduced material use of chemicals through deagglomeration in the premix

- Fast and homogeneous admixture of premixes during the mixing process

- High dispersion without temperature input due to innovative mixing tools

- No deposits and caking

- Highly precise and 100 % homogeneous admixture of carbon black, silicate and other chemicals such as plasticizers or antioxidants

From EPDM to cellular rubber. We mix all rubber raw materials.

MIXACO has profound know-how in the mixing of elastomers. We master all challenges for all common products and processes in the rubber industry.

In a MIXACO mixer for rubber production, you can process over 100 different rubber raw materials into more than 400 rubber compounds.

- TPE (Thermoplastic Elastomers)

- TPO (Thermoplastic Polyolefins)

- NR Isoprene rubber (natural rubber)

- E-SBR (styrene-butadiene rubber)

- BR (butadiene rubber)

- NBR (acrylonitrile butadiene rubber)

- CR (chloroprene rubber)

- EPDM (ethylene propylene rubber)

- Powder rubber

- Cellular rubber

- Rubber premix

- Rubber compounds. Components of rubber compounds can be divided into 4 component groups: Rubbers, fillers, plasticizers, chemicals

- Tire/tire production

- Rubber masterbatch

- Powder blends with carbon black

- Masterbatch for coloring vehicle tires of all types: car tires, motorcycle tires, tractor tires, commercial vehicle tires, bicycle tires

- etc.

Processes and functions. Blend over 100 rubber raw materials individually.

MIXACO takes a holistic view of each mixture, from processing as a starting product to the final product.

The focus is also on the entire manufacturing process in the production of elastomers. Thus, the mixing processes and parameters for precise control of the mixers can be defined.

Depending on the application, vulcanizates such as rubber or TPE must have special properties such as age resistance, low-temperature flexibility or certain strengths and elasticities.

The compounds and processes for this are precisely determined with our rubber mixers. In our test centers, we develop customized solutions with you for the best mixing quality of your rubber compounds. In this way, you achieve optimum homogenization of the components – without agglomeration.

MIXACO mixers guarantee 100% uniform distribution of fillers such as carbon black or silica to maintain the physical properties of elastomer products for the further production process.

Our mixers also process temperature-sensitive ingredients, for example when you add zinc oxide, plasticizers or crosslinking chemicals to a rubber powder.

Precisely match material and temperature input with our mixers to configure the perfect mixing process for synthetic elastomers.

The industrial production of rubber is continuously developing. With the know-how of our specialists and powerful machines, these innovations can be brought to production maturity more quickly.

That’s why leading companies around the world value MIXACO’s efficient and process-safe solutions.

Additional functions. Configure rubber mixer individually.

Depending on the mixer type, you can configure the perfect mixer for your rubber applications via numerous additional options.

- Dedusting

- Temperature measurement of the mixed material

- Aspiration heating mixer / jet filter cooling mixer

- Ventilation and feeding during the mixing process

- Dosing of liquids and gases during the mixing process

- Data recording and evaluation

- Remote maintenance

- Compatibility with existing plants

- Advanced stainless steel design

- Wear protection of the tools

- Possibility of addition in mixing position

- Special coating

- Coatings

- AGV (automatic guided vehicle) compatibility

- ATEX/NEC execution

- MIXACO Control Center

- and more

Mixer Quotation Configurator: Just 2 minutes to the perfect mixer for your raw materials.

Simply tell us your requirements and we will recommend you the optimum mixer for your raw materials and applications. Use our configurator.

With your details on quantities, mixtures, temperatures, additional functions and other information, we will prepare a customized quotation for you.

Service & Support for our industrial mixers. You can rely on us and our experienced technicians.

More than mixers. Holistic customer care for over 55 years.

Test mixer free of charge and without obligation

Test our mixers in our test center – with your own raw materials, of course.

Learn More

Mix & Process Consulting

Have your mixing process checked by our mixing professionals – free of charge & no obligation.

Learn More

The MIXACO Technical Center

In our test centers we can optimize all parameters for your compound.

Learn MoreFor further Information just get in contact with us.

Markus Frantzen

General Manager MIXACO USA

MIXACO USA LLC

1784 Poplar Drive

Greer, SC 29651

+1 (0)864 331-2320

+1 (0)864 331-2321

info@mixaco.com