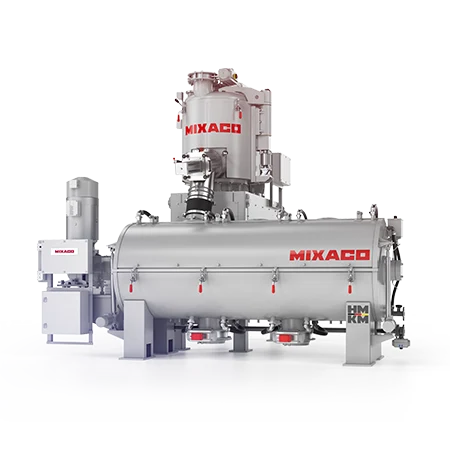

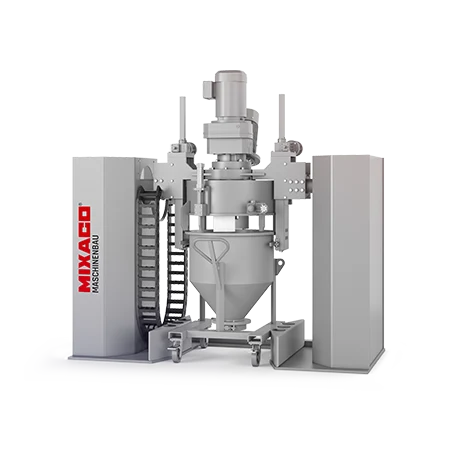

Industrial Mixer for Feedstuff

Mixer for Dry and Solid Pet Food. Mix sensitive components in consistent quality.

What would you like to mix?

In 2 minutes to your mixer.

Industrial Mixers from MIXACO: Produce Pet Food Perfectly.

The extremely fast cleaning according to hygiene standards allows frequent recipe changes and fast market introduction of new products. Mix on mixers ranging in size from 5 to over 10,000 liters – to suit your production capacities.

Our mixers solve all the challenges posed by the demanding production of pet food. Mixers and mixing results meet the high quality requirements and hygiene standards in the production of pet food.

Mixing is a very important part of the production of numerous pet food products. This is where it is decided how good the quality of the end products is and, above all, whether this quality can be consistently and reliably maintained. If the mixing result varies, this affects further processing and the end product.

MIXACO mixers mix your pet food in consistent quality every time – no matter how demanding and heterogeneous the raw materials are.

Especially for mixing natural products such as vegetable pieces, insects, shellfish, herbs, leaves or seeds, our mixers have extremely variable and sensitive mixing techniques.

Similarly, our mixers with matching accessories allow uniform coating / humidifying of all ingredients for consistent uniform composition, if required.

Feed and pet food are often produced in large quantities, but smaller quantities with rapidly changing recipes are also becoming increasingly important. Mixers for pet food must be highly variable – both in batch sizes and applications.

Benefit from our superior mixing technology “Made in Germany” and our many years of raw material experience in the pet food sector.

Our mixers are perfectly suited for demanding pet food applications and guarantee ideal mixing results.

Convince yourself of numerous advantages of our industrial mixers for the production of pet food:

Advantages

- Surfaces in contact with the product with ground and polished surfaces especially for foodstuffs

- Dust-free discharge stations

- Double jacket executions for tempering or cooling of the product to be mixed

- Mixing in less time than with conventional mixing systems – mixing time from 3 min.

- Highest quality homogenization of dry and moist mixes

- Gentle processing of sensitive feed and feed supplements

- Several process steps can be combined in one mixing system: mixing, moistening, flavoring, iodizing, coating

- High throughputs, rapid discharge and fast recipe changeover

- Batch tracing possible

- Very high degree of residual emptying

- Variable filling level

- No dead spaces or cavities in the mixing chamber

- No product contamination due to closed mixing vessel

- Batch sizes of our container mixers from 6 to > 10,000 liters

- Guaranteed mixing quality even with difficult components – for end products of consistent quality

- Extremely gentle mixing – even without heating

- 100% uniform mixing with aroma, nutrients, colors, protein, enzymes, vitamins, etc.

- Processing of fragile and irregular raw materials (cereals, flowers, leaves, etc.) without affecting them

- Dust-free mixing

- Our pet food mixers convince by easy and very safe handling

- Minimal cleaning effort for quick recipe changes: mixing tools easily accessible and demountable

- Cleaning according to hygiene standards

- Proven and low-maintenance machine technology “Made in Germany” guarantee high availability

- Various ATEX executions

- Remote maintenance and cloud monitoring

From livestock feed to vitamin preparations. We mix all dry and solid feeds.

Our mixers are ideal for dry & wet pet food and supplements. Also other products

of animal needs such as litter, bird sand or cat litter can be mixed. For example:

- Protein feed

- Litter, cat litter

- Fish food

- Flakes

- Feed tablets

- Cereals

- Legumes

- Concentrates and dry products with milk ingredients

- Grains, seeds

- Herbs, flowers, leaves, grasses, bark

- Minerals

- Rodent & small animal food

- Plants

- Veterinary medicine / medication

- Dry food

- Bird food

- Supplementary food

- Exotic food

- Extracts

- Poultry feed

- Insects, shellfish

- Grain feed

- Lick mixtures

- Cat food dry

- Dog food dry

- Farm animal feed – pig feed, cattle feed, chicken feed etc.

- Pellets, compresses, extrudates, sticks

- Horse feed – muesli, mineral feed, cobs, herbs, mash, vitamins etc.

- Roughage

- Turtle food

- Sensitivity feed

- Special feed

- Pigeon feed

- Vitamin powder

- Bird sand

- etc.

Mixing Techniques. Individual Mixers for Pet Food Manufacturing.

Our mixers are ideal for a wide range of applications in feed production and the manufacture of sophisticated nutritional supplements. For example:

- Homogenize

- Agglomerate

- Dispersing

- Moistening / Wetting

- Heating / Cooling

- Coating

- Compaction

- Powder emulsions

- Producing uniform finished and semi-finished products

- Processing of sensitive ingredients that contain chunks or that swell during mixing

- Highly precise and uniform blending of vitamins and nutrients

- Addition of aromatic and essential oils

- Add liquids such as lysine or oil to powder blends without clumping

- Contamination-free addition of formulationingredients for veterinary drugs and foodsupplements

- Mixing without temperature to keep feed cool and free-flowing

- etc.

Additional Functions. Tailor-made Pet Food Mixer.

By means of various additional options, our mixers are perfectly adapted to the production of your pet foods:

- Mixing head cooling

- Dedusting

- Temperature measurement of the mixed material

- Ventilation and feeding during the mixing process

- Dosing of liquids and gases during the mixing process

- Data recording and evaluation

- Remote maintenance

- Compatibility with existing plants

- Advanced stainless steel design

- Wear protection of the tools

- Possibility of addition in mixing position

- Special coating

- Coatings

- AGV (automatic guided vehicle) compatibility

- ATEX/NEC execution

- Remote maintenance

- Cloud monitoring (MIXACO Control Center)

- And others

Mixer Quotation Configurator: Just 2 minutes to the perfect mixer for your raw materials.

Simply tell us your requirements and we will recommend you the optimum mixer for your raw materials and applications. Use our configurator.

With your details on quantities, mixtures, temperatures, additional functions and other information, we will prepare a customized quotation for you.

Service & Support for Industrial Mixers. You can rely on us and our experienced technicians.

More than mixers. Holistic customer care for over 60 years.

Test mixer free of charge and without obligation

Test our mixers in our test center – with your own raw materials, of course.

Learn More

Mix & Process Consulting

Have your mixing process checked by our mixing professionals – free of charge & no obligation.

Learn More

The MIXACO Technical Center

In our test centers we can optimize all parameters for your compound.

Learn MoreFor further Information just get in contact with us.

Ed Ford

Sales Manager USA

MIXACO USA LLC

1784 Poplar Drive

Greer, SC 29651

+1 (0)864 331-3319

+1 (0)864 331-2321

info@mixaco.com