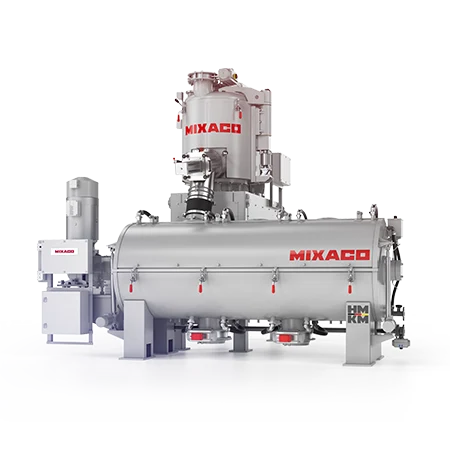

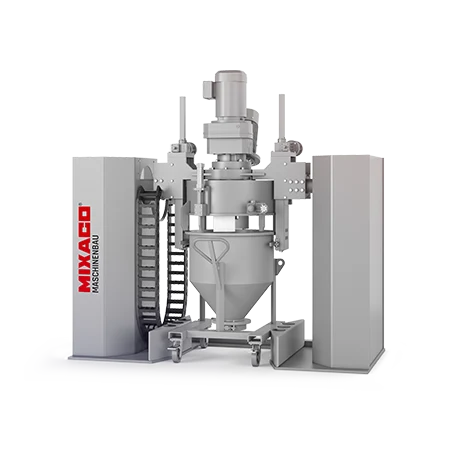

Industrial Mixer for Foodstuff

Reduce costs through fast recipe changes. Mix a wide variety of solid foods with consistent quality.

What would you like to mix?

In 2 minutes to your mixer.

Stationary Mixers and Container Mixers. Mixing Foodstuff Perfectly.

Our mixers solve all challenges in the production of high quality food. MIXACO mixers and their mixing results meet the high quality requirements and hygienestandards in food production.

Mixing is an important production step in the manufacture of countless food products. The consistent mixing quality determines the quality of the end products.

MIXACO mixers blend food products in consistent quality every time – no matter how challenging and heterogeneous the raw materials are.

Whether sensitive natural products or sensitive additives – our food mixers have extremely variable and sensitive mixing techniques ready for every application.

Our food mixers are characterized by very short mixing times compared to commercially available mixing systems. The intensive and excellent homogenization of the mixed material is achieved between 3 to 6 minutes mixing time.

Extremely gentle mixing – even without heating – allows the most sensitive foods and dietary supplements to be mixed. The right temperatures are important so that nutrients and vitamins are completely preserved.

The appropriate tools help to achieve the best mixing result without compromising the quality of the raw materials used.

Food safety aspects, such as the avoidance of dust in the product, are taken into account during the mixing process.

Our food mixers also impress with very simple handling as well as legendary fast and easy cleaning.

Food products are often produced in large quantities, but smaller quantities and rapidly changing recipes are also becoming increasingly important. Mixers for the food industry must be highly variable – both in terms of batch sizes and applications.

Benefit from our superior mixing process “Made in Germany” and our many years of raw material experience in the field of food, feed and dietary supplements.

Convince yourself of the advantages of our food mixers:

Advantages

- Surfaces in contact with the product are executed with ground and polished surfaces especially for food agents

- Low dust discharge stations

- Double jacket executions for temperature control or cooling of food products

- Reduction of process time by mixing in less time than standard mixing systems on the market

- Homogenize dry & moist food in highest quality

- Realize several process steps in one mixer: Mixing, moistening, flavoring, iodizing, coating

- High throughputs, rapid discharge and fast recipe changeover

- Batch backtracking possible

- High degree of residual emptying

- Variable filling level

- No dead spaces or cavities in the interior of the mixer

- No product contamination due to closed mixing vessel

- The batch sizes of our mixers are scalable from 6 to > 10,000 liters and grow with your production capacities

- Intensive and excellent homogenization of the mixed product is often achieved after only 3 minutes mixing time

- Mixing quality is guaranteed even with difficult components – for end products of consistent quality

- Due to extremely gentle mixing – even without heating – even the most sensitive raw materials can be homogenized

- A wide variety of foods can be completely uniformly provided with flavor, nutrients, colors, proteins, enzymes, vitamins, etc.

- Our mixers process fragile and irregular food products (cereals, flakes, flowers, leaves, etc.) without affecting their physical properties or even breaking them

- Aspects of food safety, such as avoiding dust in the product, are taken into account during the mixing process

- Our food mixers convince by simple and very safe handling

- Minimal cleaning effort for quick recipe changes: mixing elements and mixing tools easily accessible and demountable

- Cleaning according to hygienic standards in food production

- Proven and low-maintenance machine technology “Made in Germany” guarantee high availability

- Various ATEX executions

- Remote maintenance and cloud monitoring

From Aroma to Sugar. We mix solid foodstuff.

Our food mixers are ideal for all dry & wet foods. Here is a selection of foods and food additives that can be mixed:

- Flavors

- Candies

- Effervescent tablets

- Blossoms / Leaves

- Broth

- Cornflakes

- Desserts

- Ice cream powder

- Fat powder

- Flakes

- Flavor enhancer

- Spices

- Spice mixtures

- Freeze-dried soups

- Yeast

- Herbs

- Food coloring

- Lecithin powder

- Powder for energy drinks

- Puffed rice

- Salts

- Trace elements

- Starch

- (Dry) Sauce mixes

- Vitamins and minerals

- Ready to bake flours

- Baking mixtures

- Enzymes / Starter cultures

- Semolina

- Baked goods

- Flavorings

- Instant soups

- Instant beverage powder

- Coffee and tea extracts

- Cocoa

- Cookies

- Pudding powder

- Powdered sugar

- Food supplements

- Nuts / Nut mixtures

- Muesli / Cereals

- Milk powder, whey powder

- Sports nutrition

- Sweeteners

- Confectionery

- Tea blends

- Dried vegetables

- Dried fruit

- Dry sourdough

- Wine gum

- Sugar

- etc.

Mixing Techniques. Mix even fragile foods perfectly.

Our food mixers are not only capable of simple mixing, but can also carry out a wide range of other processes. In addition to the classic basic process of dry mixing, the additional processes frequently required in the food industry can be carried out within a mixing system.

Besides to excellent food homogenization, MIXACO mixers can process and homogenize a wide variety of foods in a variety of ways.

Our food mixers produce uniform finished and semi-finished products and are suitable for a wide range of food manufacturing processes. Here are just a few examples:

- Homogenize

- Agglomerate

- Dispersing

- Coating

- Humidifying / Wetting

- Heating

- Cooling

- Mixing

- Compaction

- Flavoring

- Iodizing

- Mixing in additives

- Injecting liquids

- Dispersing sweeteners

- Creating powder emulsions for soft drinks

- Mixing breadcrumbs

- Mixing of raw materials containing pieces

- Processing of foods that swell during mixing

- Preparation of powders with liquid injection

- Preparation of products with emulsifiers

- etc.

The preparation of powdered foods is a strength of our mixers. For example, ice cream powder, aromas, flavors, enzymes, vanilla sugar, cocoa, or ready-to-bake flour mixtures can be mixed perfectly.

The preparation of granulated foodstuffs is just as perfect. This applies, for example, to table salts, coffee / tea blends, instant beverages, or milk powder.

The preparation of fragile foods is also carried out quickly and yet absolutely gently by our food mixers. For example, cereals, pastries, cookies, dried soups, flowers, herbs, bouillon cube masses, spice mixtures or dried vegetables can also be processed.

Additional Functions. Tailor-made Food Mixer.

By means of various additional options, our mixers are perfectly adapted to the production of your foodstuffs:

- Mixing head cooling

- Dedusting

- Temperature measurement of the mixed material

- Ventilation and feeding during the mixing process

- Dosing of liquids and gases during the mixing process

- Data recording and evaluation

- Remote maintenance

- Compatibility with existing plants

- Advanced stainless steel design

- Wear protection of the tools

- Possibility of addition in mixing position

- Special coating

- Coatings

- AGV (automatic guided vehicle) compatibility

- ATEX/NEC execution

- Remote maintenance

- Cloud monitoring (MIXACO Control Center)

- And others

Mixer Quotation Configurator: Just 2 minutes to the perfect mixer for your raw materials.

Simply tell us your requirements and we will recommend you the optimum mixer for your raw materials and applications. Use our configurator.

With your details on quantities, mixtures, temperatures, additional functions and other information, we will prepare a customized quotation for you.

Service & Support for Industrial Mixers. You can rely on us and our experienced technicians.

More than mixers. Holistic customer care for over 55 years.

Test mixer free of charge and without obligation

Test our mixers in our test center – with your own raw materials, of course.

Learn More

Mix & Process Consulting

Have your mixing process checked by our mixing professionals – free of charge & no obligation.

Learn More

The MIXACO Technical Center

In our test centers we can optimize all parameters for your compound.

Learn MoreFor further Information just get in contact with us.

Markus Frantzen

General Manager MIXACO USA

MIXACO USA LLC

1784 Poplar Drive

Greer, SC 29651

+1 (0)864 331-2320

+1 (0)864 331-2321

info@mixaco.com