Granulate Mixer

Granulate mixer for extrusion, injection molding and blow molding. Mix 5 to 10,000 liters of granules per batch.

What would you like to mix?

In 2 minutes to your mixer.

Advantages of our Granulate Mixers. Perfect homogenization – high-precision dosing.

MIXACO granulate mixers are suitable for all plastic granulates and numerous other granulates from a wide range of industries.

Benefit from superior mixing technology “Made in Germany” and our more than 50 years of experience in mixing a wide variety of granules, flakes and powders.

Convince yourself of the advantages of our granulate mixers:

- Excellent homogeneity

- Uniform granulation of a wide variety of raw materials

- High-precision gravimetric or volumetric metering of masterbatches, additives, etc.

- Customized production of individual dosing applications

- Perfect mixing in only 3 – 6 minutes

- Fast and easy cleaning

- Low energy consumption

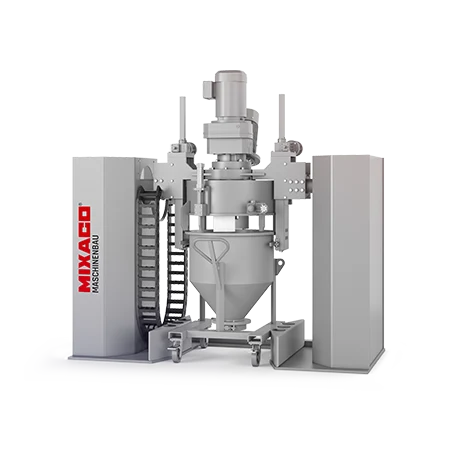

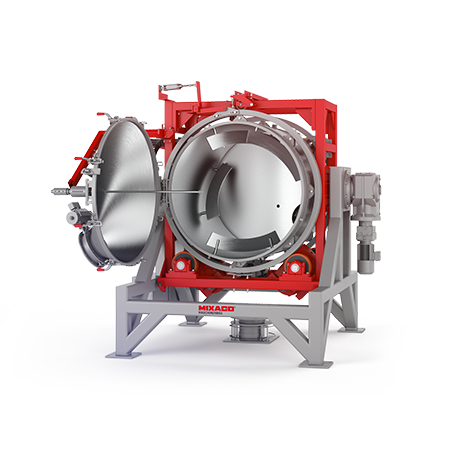

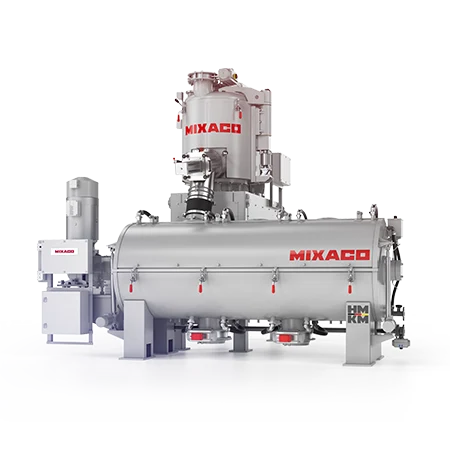

- Discontinuous, continuous, stationary and container granulate mixers

- Low maintenance requirements and cost-saving, use-dependent maintenance

- Dust-free discharge stations

- Double jacket designs for temperature control / cooling of the granules

- Stainless steel design / special coating for the food industry

- Sampling during the mixing process

- Reduction of process time by mixing in less time than with commercially available mixing systems

- High throughputs, rapid emptying and quick recipe changes

- Batch tracing possible

- Very high degree of residual emptying

- Variable filling level

- No product contamination due to closed mixing container

- No dead spaces or cavities in the mixer interior

- Sizes of our mixers from 5 to 10,000 liters

- Mixing quality is guaranteed even with difficult components – for end products of consistent quality

- Extremely gentle mixing – even without heating if required – allows even the most sensitive raw materials to be homogenized

- Our plastic granulate mixers convince by simple and very safe handling

- Minimal cleaning effort for fast recipe changes: mixing elements and mixing tools are easily accessible and can be dismantled

- Proven, low-maintenance machine technology “Made in Germany” guarantees minimum downtime and high availability of the production plant

- Granulate mixers with ATEX versions

- All mixing parameters individually adjustable

- Test granulate mixer free of charge

- Innovative cloud monitoring of the granulate mixers via the MIXACO Control Center (MCC)

What granules can be mixed? All!

MIXACO granulate mixers are suitable for granulates from various raw materials and for many industries. Granules are important for the production of countless products – their reliable quality influences further processing and the quality of the final products.

Our granulate mixers are as versatile and flexible as the demanding processing of granulates requires. You can convince yourself of this during a free mixer test in our test center.

Our mixers can be individually configured for granules with a wide range of properties. Even sensitive materials are gently and uniformly granulated – in consistent quality.

- Plastic granules (PVC, WPC, SPC, PTFE, HDPE, ABS, PP etc.)

- Tablet masses for pharmaceutical products and food supplements

- Beverage powders

- Baking agents

- Sweeteners

- Feedstuffs for livestock and pets

- Cellulose derivatives

- Building material granules such as cement, plaster or concrete

- Granules as a basis for adhesives

- Carbon black and black pigment derivatives

- Granules for detergents & cleaning agents

- Fertilizer granules

- Pesticides, herbicides, fungicides

- Various chemical granules

- Ceramic colors

- Granules for injection molding machines, extruders & 3D printers

- Metal powders

- And much more

Mixer Quotation Configurator: Just 2 minutes to the perfect mixer for your raw materials.

Simply tell us your requirements and we will recommend you the optimum mixer for your raw materials and applications. Use our configurator.

With your details on quantities, mixtures, temperatures, additional functions and other information, we will prepare a customized quotation for you.

Mixing Processes. Various mixing processes can be used.

MIXACO granulate mixers feature sophisticated, innovative and patented mixing technologies to optimally mix and process your granulates:

- Mixing & homogenizing

- Gravimetric & volumetric dosing of liquids

- Surface granulation

- Coating

- Dispersing

- Agglomerate

- Deagglomeration

- Compaction

- etc.

Options. Customize granule mixer for your requirements.

MIXACO granulate mixers are available in various shapes and sizes and are suitable for countless mixing and processing techniques.

We have laboratory mixers with which you can mix granules from 5 liter batch size. With our drum and bag mixers you can mix up to 100 liters of granules in bags or up to 200 liters of granules in drums. Mixers with up to 10,000 liters volume are possible.

For larger throughput quantities and the most diverse requirements, we have horizontal mixers, vertical mixers, stationary mixers, container mixers, cone mixers, batch mixers, continuous mixers, etc. Tell us what you want to mix and how – we will configure the perfect mixer for your granules including a quotation. Use our quotation configurator for this.

Via various additional options, our granulate mixers are perfectly adapted to the processing of your granulates and raw materials:

- Dedusting

- Temperature measurement

- Aeration and feeding during the mixing process

- Dosing / spraying / injection of liquids and gases during mixing (volumetric / gravimetric)

- Special design & coating for the food industry

- ATEX executions: Nitrogen inerting with oxygen concentration measurement

- Data recording and evaluation

- Remote maintenance

- Hygienic design

- Cooling, heating, drying

- Batch mixers / discontinuous or continuous mixers

- Mixing under vacuum, drying, coating

- Mixing under pressure

- etc.

As the inventor of the container mixer, we at MIXACO are committed to innovation in industrial mixing technology.

Service & Support for our Granulate Mixers. You can rely on us and our experienced technicians.

For further Information just get in contact with us.

Ed Ford

Sales Manager USA

MIXACO USA LLC

1784 Poplar Drive

Greer, SC 29651

+1 (0)864 331-3319

+1 (0)864 331-2321

info@mixaco.com