MIXACO Heating/Cooling Mixer

MIXACO Heating/Cooling Mixer. For throughputs up to over 8,000 kg/h.

Benefits at a glance. Fast mixing – fast cleaning.

- Can be used for different applications such as heating, agglomerating, bonding

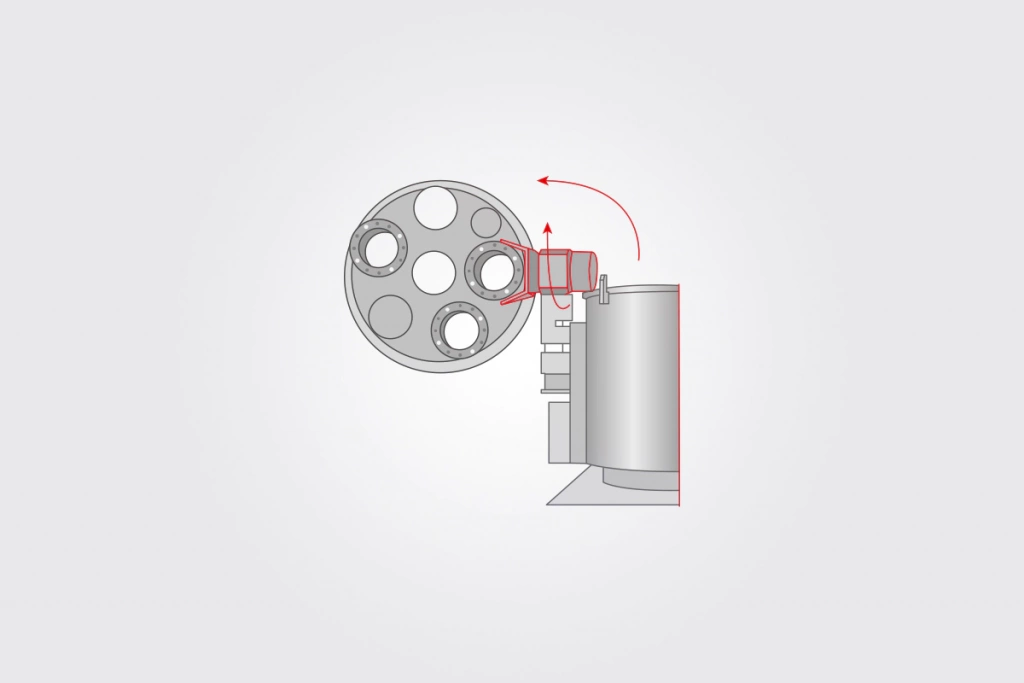

- Process-optimized tools that can be changed quickly

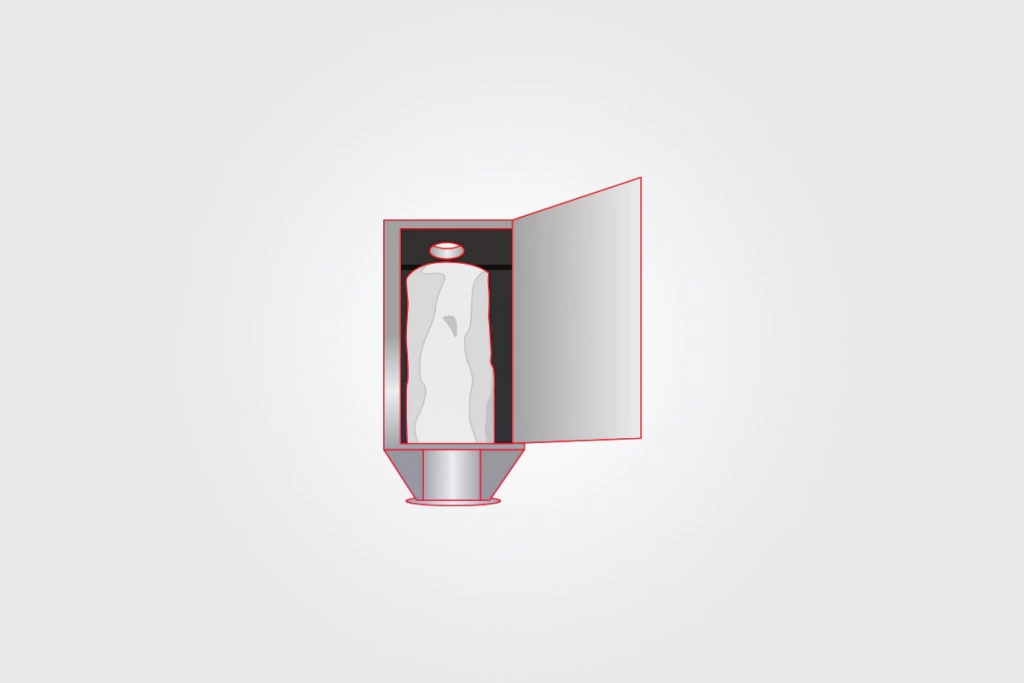

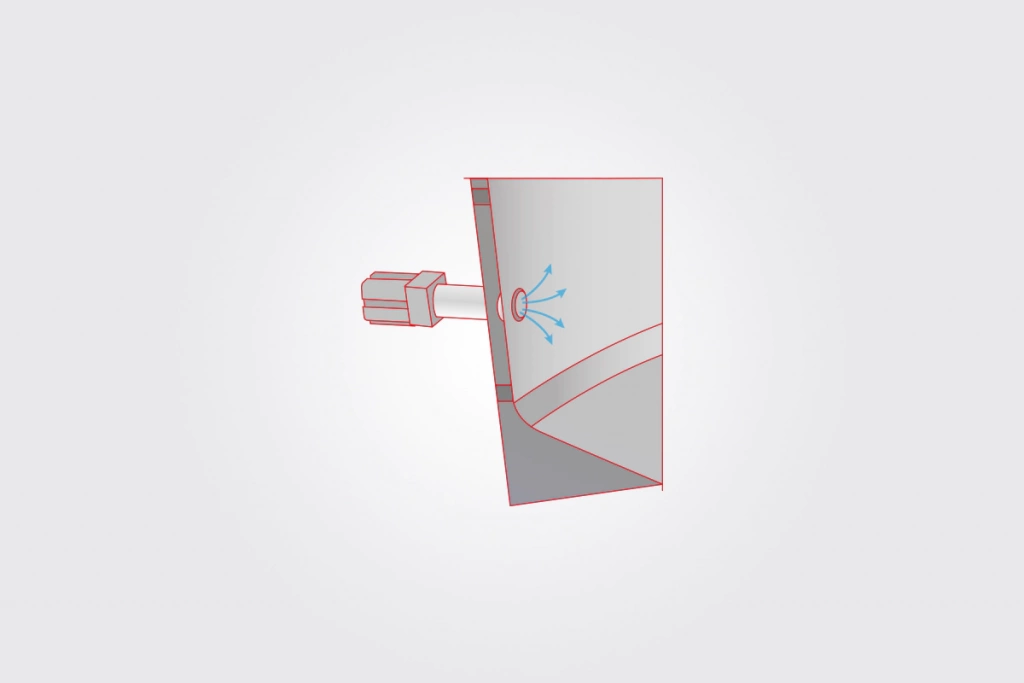

- Integrated aspiration with targeted air flow guarantees optimal evacuation of dust and moisture particles

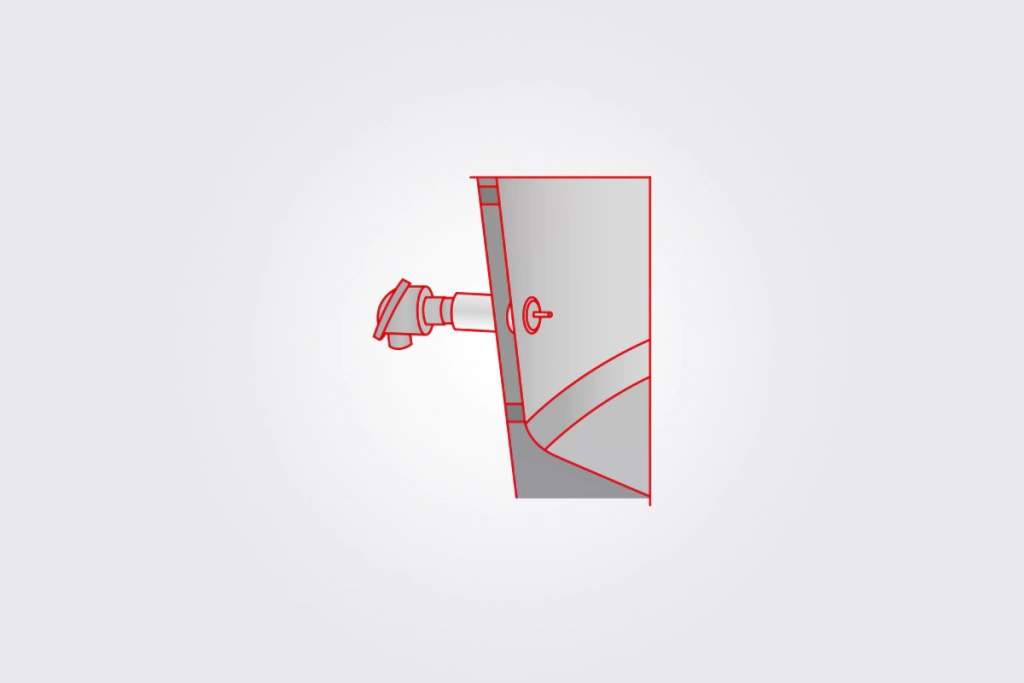

- Heating mixers are always double-walled

- No formation of deposits in PVC formulations with hygroscopic stabilizers – prevents defects on extruder and end product

- Full insulation of heating mixers possible

- Vertical heating-cooling mixer for throughputs up to 2,500 kg/h

- Horizontal heating-cooling mixer for throughputs up to > 8,000 kg/h

- Performance-optimized selection of mixer drives for high energy efficiency

- Innovative aspiration for optimum dehumidification of the mixture

- Extensive range of additional equipment for individual adaptation to customer requirements

- ATEX versions possible

What would you like to mix?

In 2 minutes to your mixer.

Control. Clearly arranged control panel.

The control of our heating-cooling mixer combinations is based on a Siemens S7-1500 PLC and meets today’s requirements for safety, efficiency and economy.

The development and programming of the control system from a single source ensures optimum integration of the mixer components.

Alternatively, it is also possible to use Allen-Bradley components (incl. Panelview operating unit). The control can also be designed according to UL / NEMA. In addition, the control can be equipped with an interface for data exchange as a higher-level control.

Operating Modes

- Manual mode

- Automatic Mode

- Cleaning Mode

Process parameters

- Mixing parameters

- Mixing time

- Mixing tool speed

- Current consumption mixing drive

- Torque (optional)

- Liquid injection (optional)

Process visualization

- System status

- Process parameters

- Machine setting

- Error management

A Siemens TP1200 operator panel (12″ color display with touch operation and Ethernet interface) is used for operation and process visualization.

The control panel offers function-oriented operation of the heating/cooling mixer combination in manual or automatic mode. The mixing parameters are entered and managed in tabular form through individual work steps.

The operating panel offers function-oriented operation of the heating/cooling mixer combination in each work step, the parameters time, temperature, current, speed, liquid addition, etc. can be freely defined and stored in a mixing program. The mixing parameters are entered and managed in tabular form through individual work steps.

Up to 99 mixing programs are available via the control panel. Optionally, the control system can be equipped with integrated remote maintenance.

Functionality. For perfect mixing results.

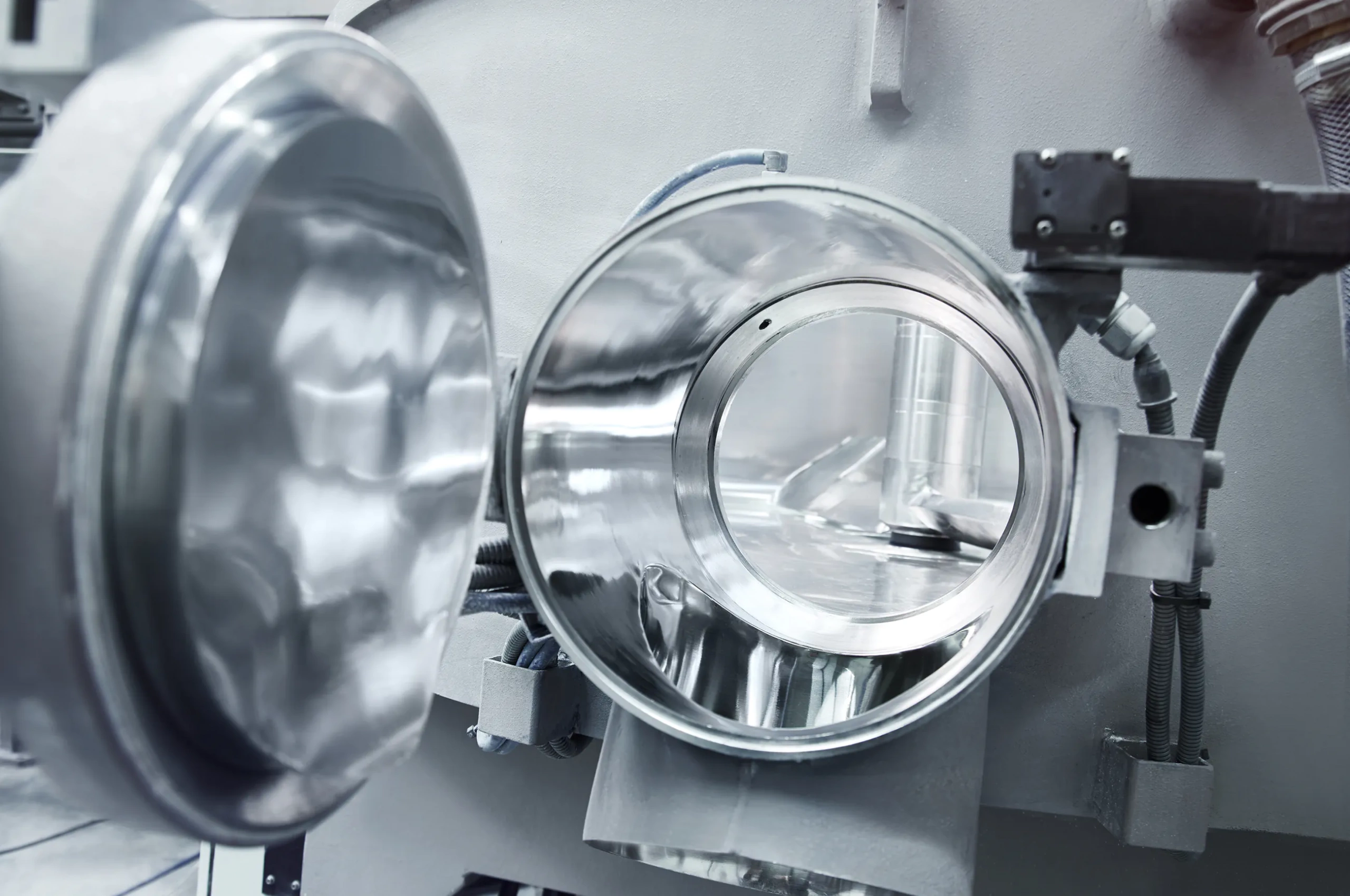

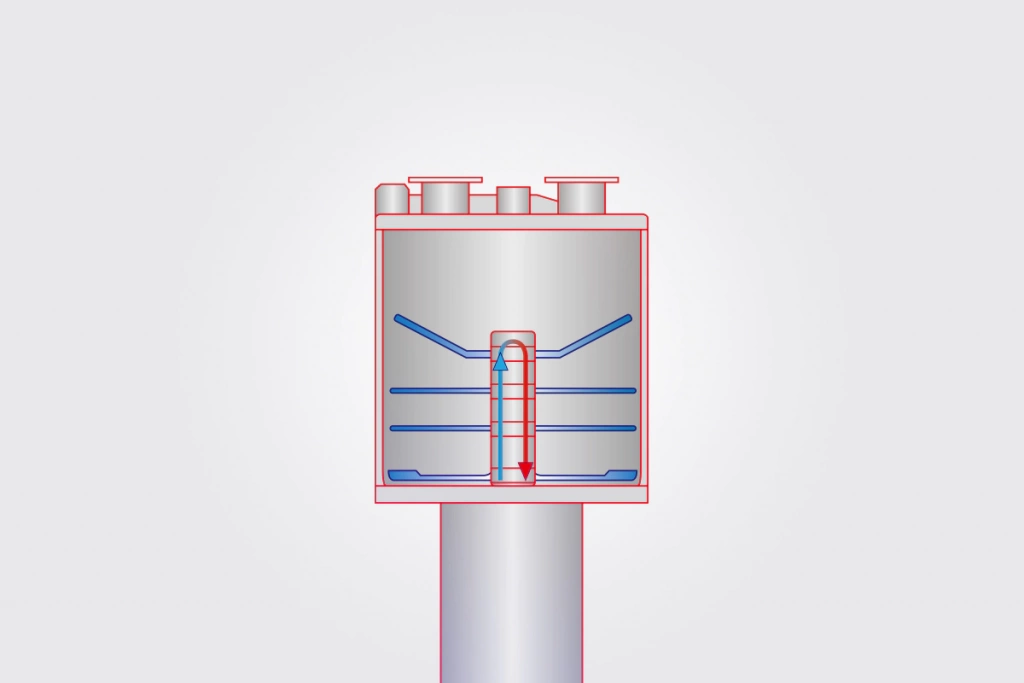

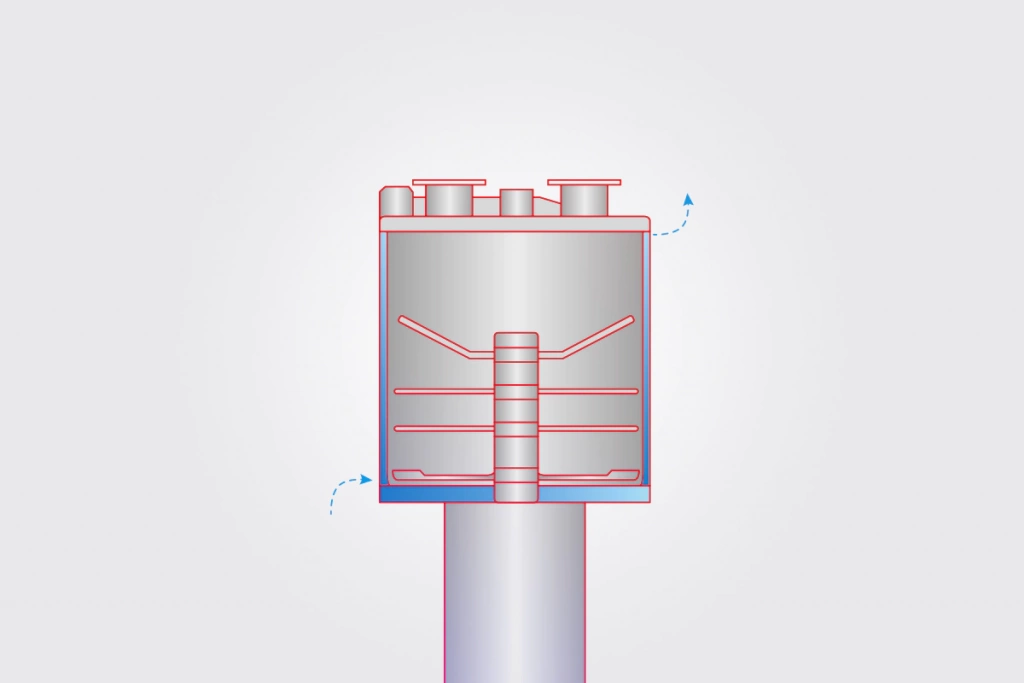

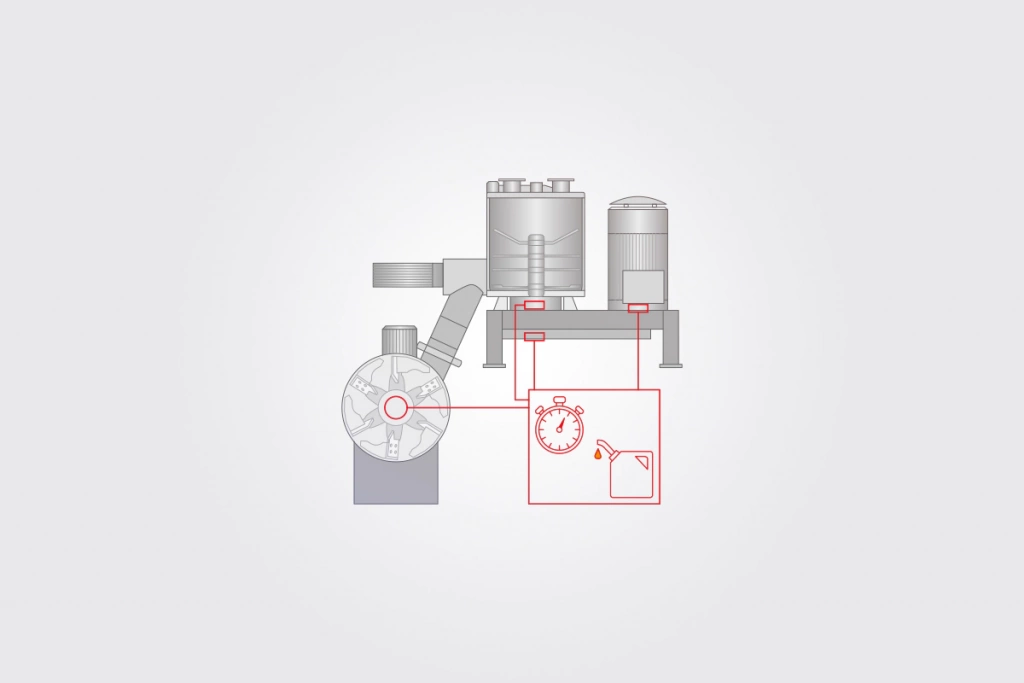

In the heating mixer, the modular mixing tool, which forms a mixing drum at a circumferential speed of 10 – 40 m/s, generates a high friction power, which leads to the heating of the material to be mixed.

The mixing drum distributes all recipe ingredients evenly, resulting in a homogeneous mixture.

Once the desired target temperature has been reached, the mix is discharged into the connected cooling mixer via the contour-shaped outlet.

Whether heating or tempering, coating, agglomerating or dispersing – a wide variety of processes and optimum adaptation to customer requirements can be perfectly realized using the modular concept of the heating mixer.

Mixing methods. Various applications for high outputs.

MIXACO heating/cooling mixers are suitable for numerous mixing processes in the high throughput range. Our mixers guarantee the best mixing quality for a wide range of applications.

The precise coordination of the technology as well as the control parameters are created by our specialists together with you.

Applications

- Homogenize

- Dispersing

- Coloring

- Preparation

- Agglomeration

- Comminution

- Drying

- Coating

- Bonding

- Wetting

- Fiber pulping and dyeing

- and much more

Heating/Cooling Mixer vertical. Throughputs up to 3,000 kg/h.

An economic and reliable mixer solution

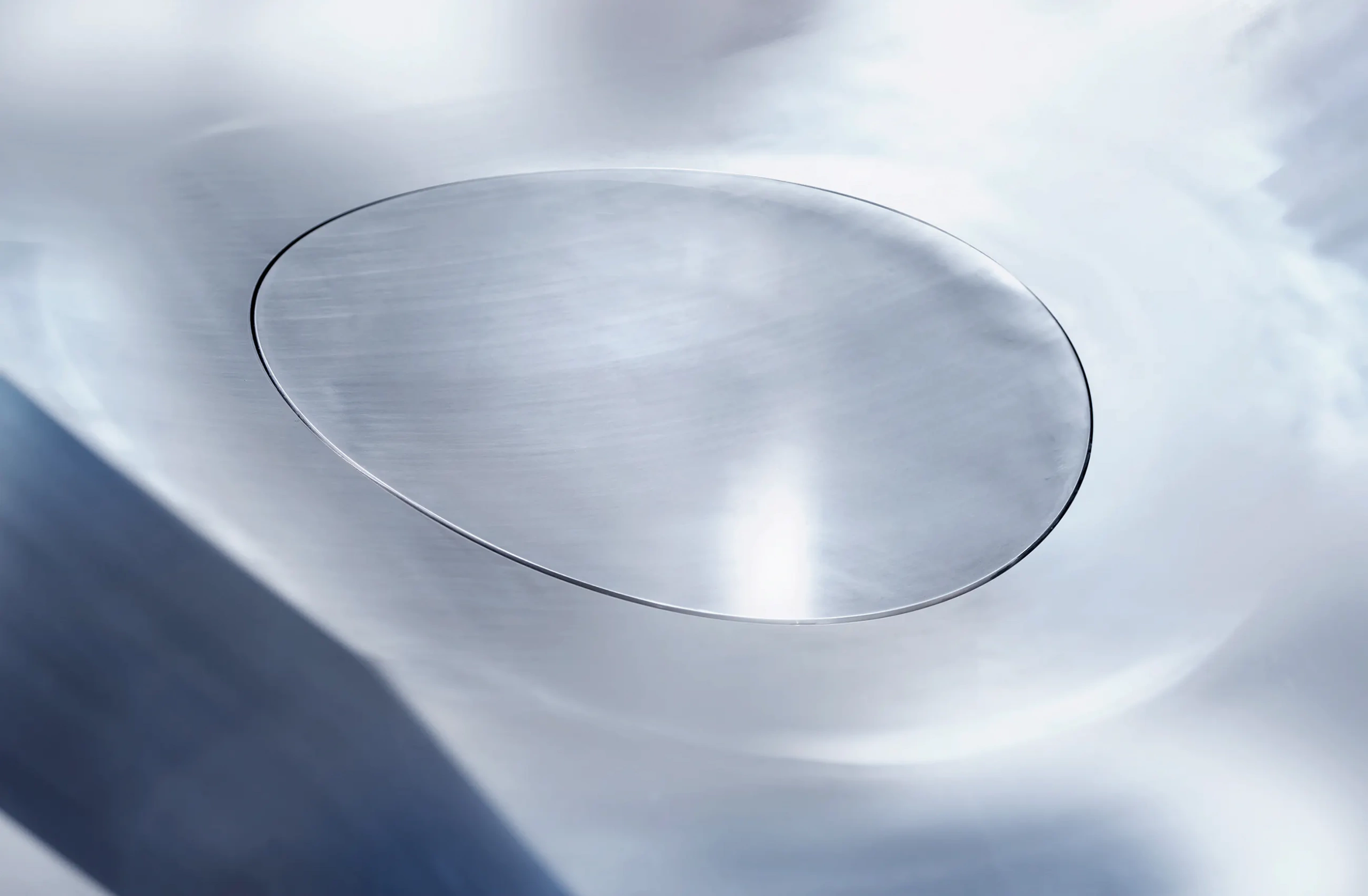

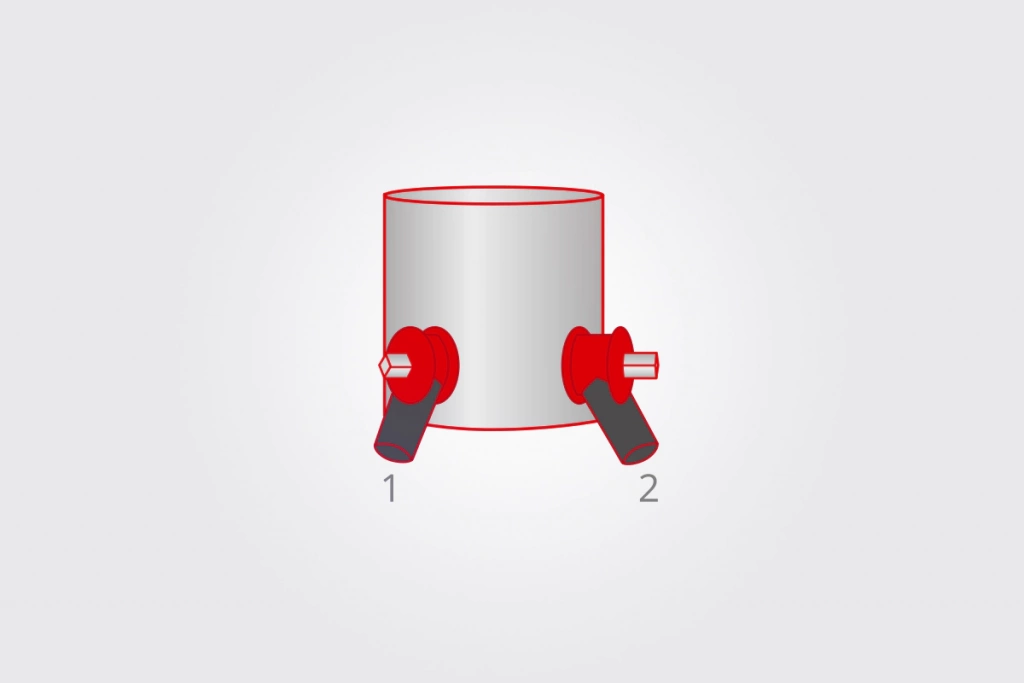

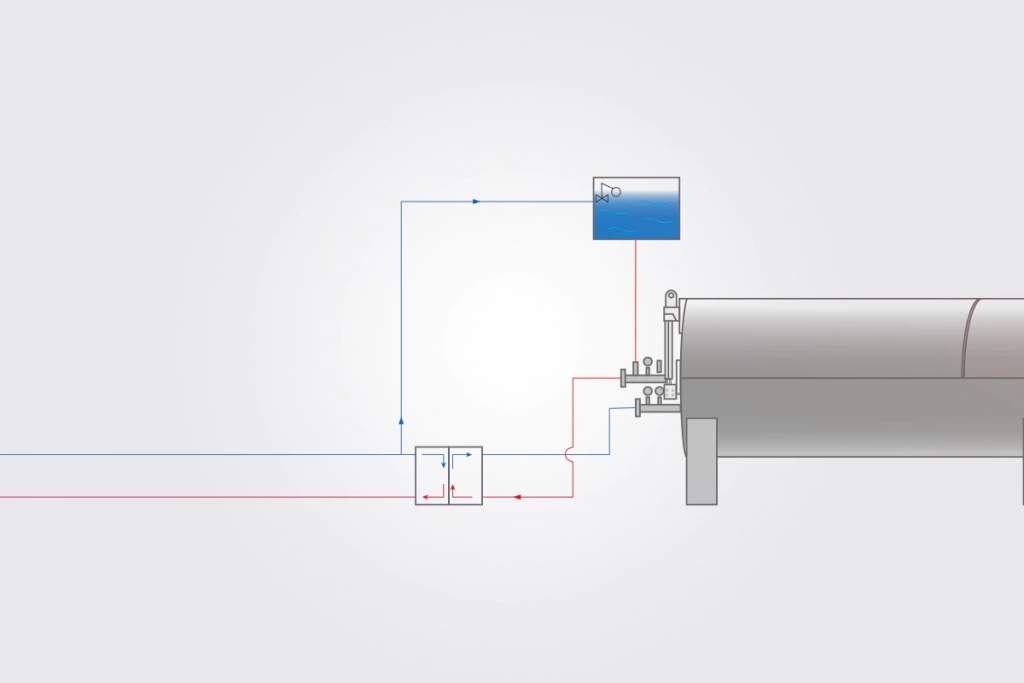

In the vertical cooling mixer, the material to be mixed is cooled by gentle material circulation on a cooled surface. A targeted water supply in the mixer bottom and in the side wall ensures optimum cooling performance of the mix. After completion of the mixing process, the cooled mix is quickly discharged via the contour-shaped outlet.

Benefits

- Optimal water flow in the mixer bottom and side wall for high cooling capacity

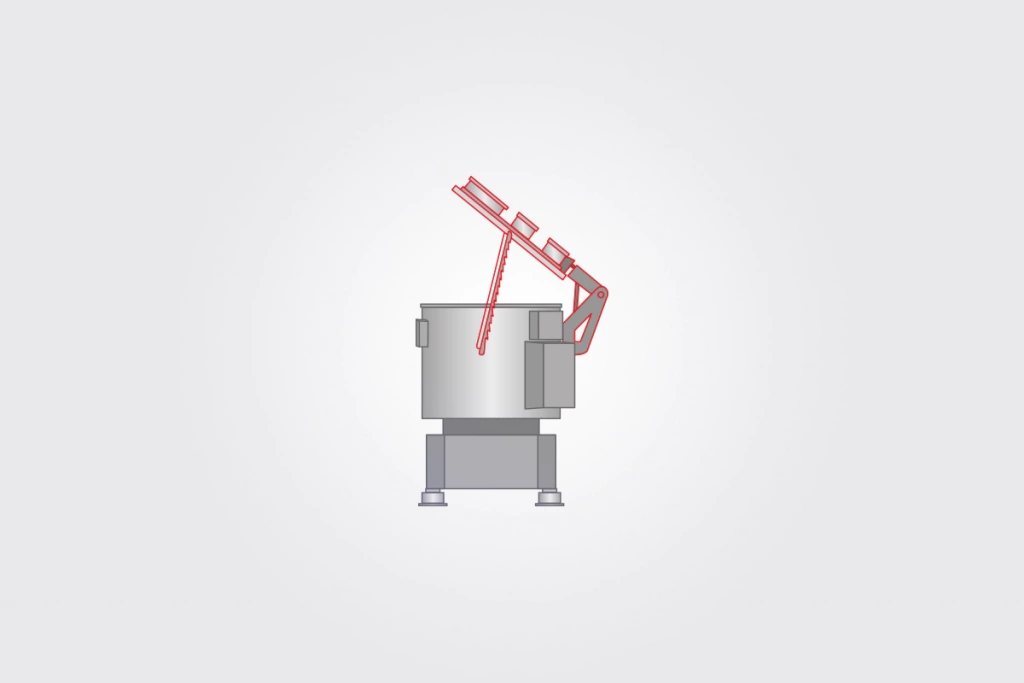

- Easy and quick cleaning via the opened swivel lid

Mixer Sizes – Heating Mixer (HM) with vertical Cooling Mixer (KM-V)

| Mixer Sizes | Manual Dosage 5 Batches/h (kg/h) | Engine Power HM in kW | Engine Power KM in kW |

|---|---|---|---|

| HM 200 KM 800 | 425 | 45 | 7.5 |

| HM 200 KM 1200 | *425 | 45 | 11 |

| HM 400 KM 1700 | 1600 | 110 | 18.5 |

| HM 500 KM 1700 | *850 | 132 | 22 |

| HM 600 KM 2500 | 1060 | 160 | 22 |

| HM 800 KM 2500 | *1060 | 200 | 30 |

Special sizes on request.

Note: The table data are approximate values which must be confirmed by MIXACO.

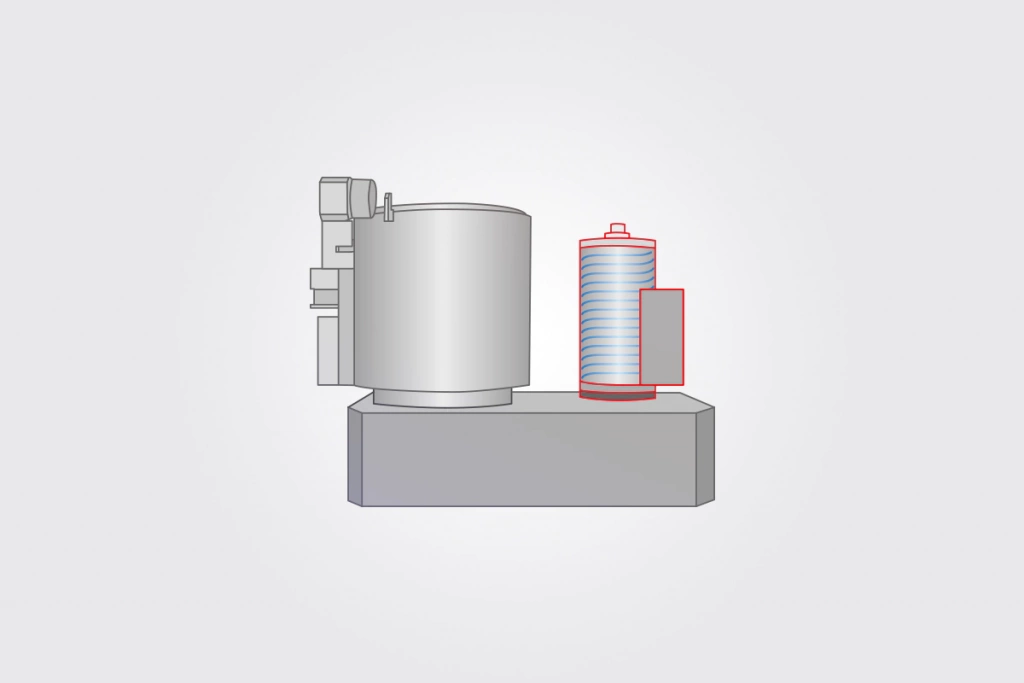

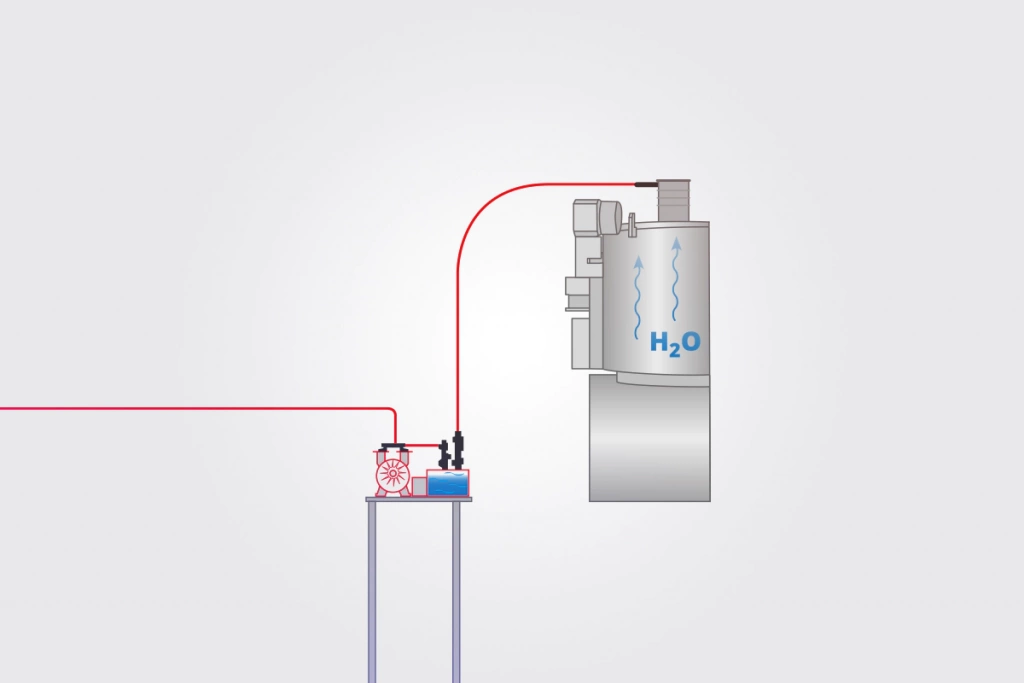

Heating Mixer with horizontal Cooling Mixer HM + KMH. Throughputs up to 8,000+ kg/h.

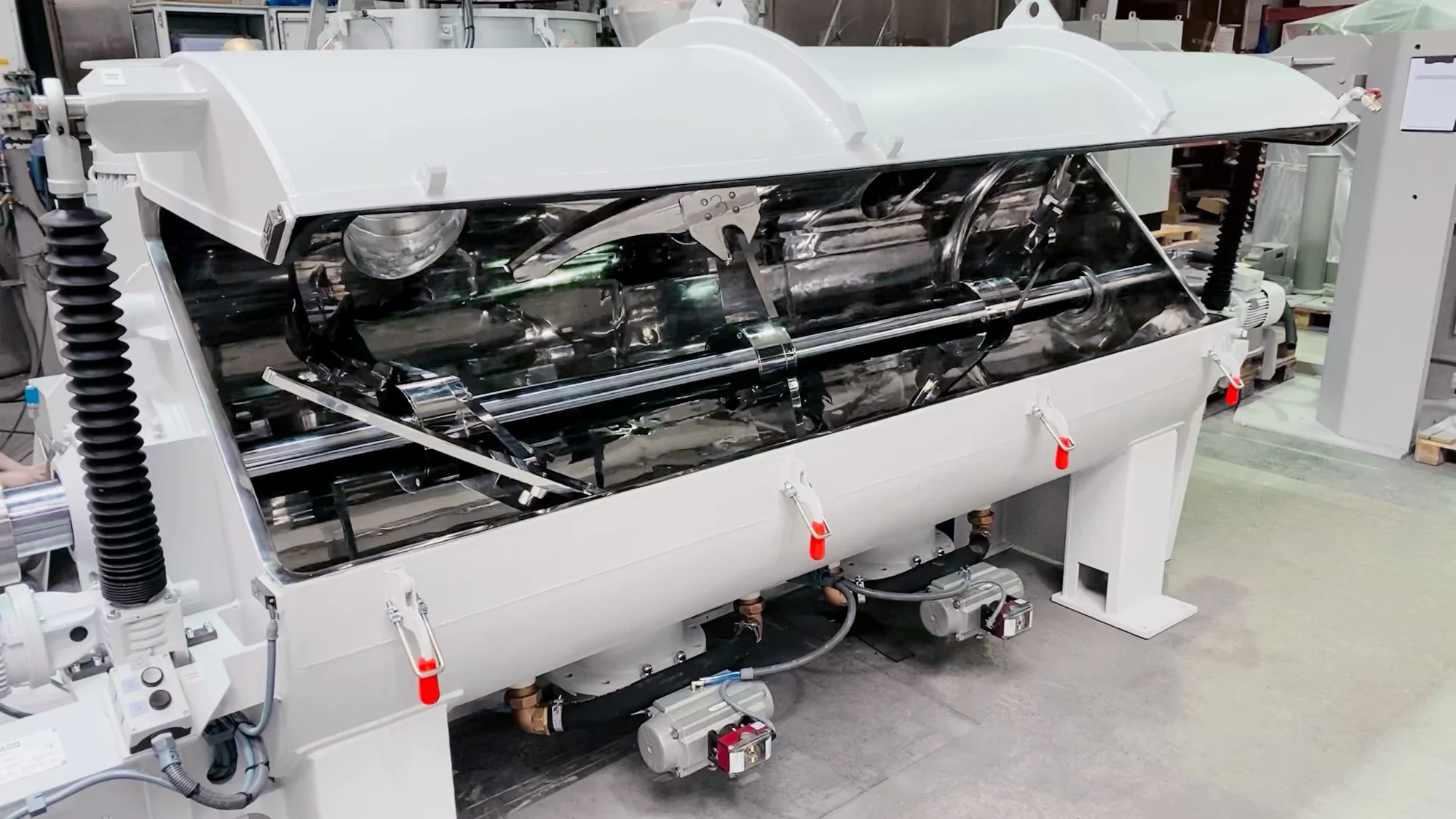

High performance mixers with high throughputs

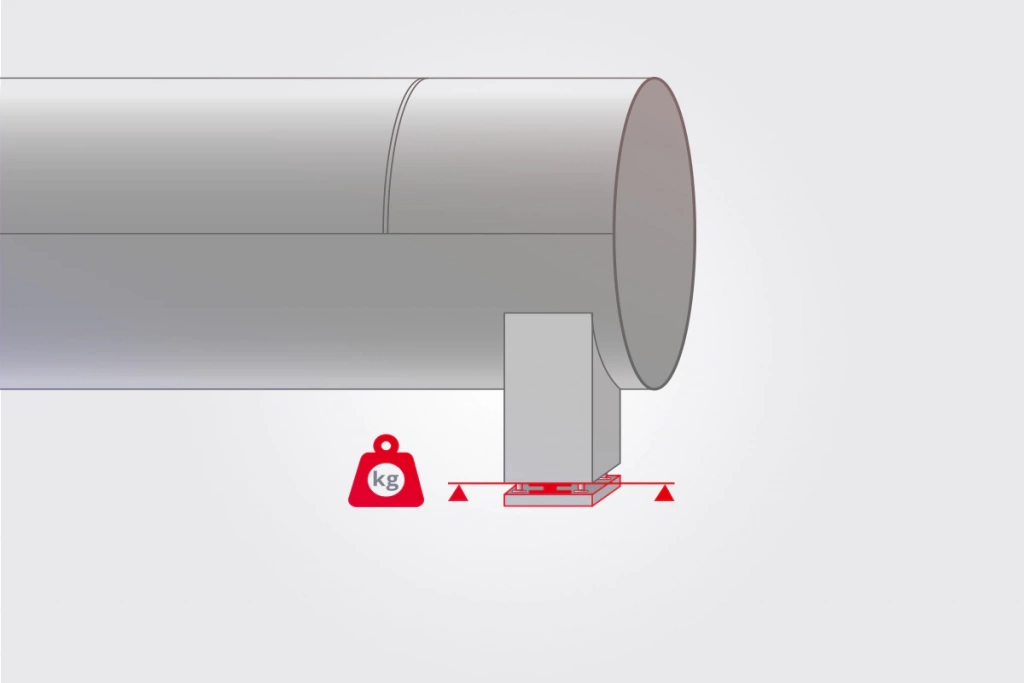

Thanks to its design, the horizontal cooling mixer has a very high and efficient cooling capacity. Separate cooling zones, distributed around the circumference, enable uniform and reliable cooling of the mix within a very short time.

In combination with an optimum cooling water speed, short cooling times and thus consistently high throughput rates can be realized.

Quick and easy cleaning is possible via the large container lid, operated by electromechanical linear drives.

Benefits

- Optimum cooling capacity due to large cooling surfaces and targeted water flow in the tank and lid

- Good accessibility for cleaning due to large lid

Mixer sizes hard PVC Heating Mixer (HM) with horizontal Cooling Mixer (KM-H)

Parameters

Bulk density: 0.5 kg/Ltr.

Heating temperature: 120 °C | Cooling temperature: 50 °C (*40 °C)

Filling level: 85 %

| Mixer Sizes | Manual Dosage 5 Batches/h (kg/h) | Semi Automatic Dosage 6 Batches/h (kg/h) | Automatic Dosage 8 Batches/h (kg/h) |

|---|---|---|---|

| HM 200 KM 800 H | 425 | 510 | 680 |

| HM 200 KM 1200 H | *425 | *510 | *680 |

| HM 300 KM 1200 H | 635 | 762 | 1016 |

| HM 400 KM 1200 H | 850 | 1020 | 1360 |

| HM 400 KM 2000 H | *850 | *1020 | *1360 |

| HM 500 KM 2000 H | 1060 | 1272 | 1696 |

| HM 500 KM 2600 H | *1060 | *1272 | *1696 |

| HM 600 KM 2000 H | 1275 | 1530 | 2040 |

| HM 600 KM 2600 H | *1275 | *1530 | *2040 |

| HM 700 KM 2600 H | 1500 | 1800 | 2400 |

| HM 700 KM 3700 H | *1500 | *1800 | *2400 |

| HM 800 KM 2600 H | N/A | 2040 | 2720 |

| HM 800 KM 3700 H | N/A | *2040 | *2720 |

| HM 1000 KM 3700 H | N/A | 2550 | 3400 |

| HM 1000 KM 5000 H | N/A | *2550 | *3400 |

| HM 1200 KM 5000 H | N/A | 3060 | 4080 |

| HM 1500 KM 5000 H | N/A | N/A | 5096 |

| HM 1500 KM 7000 H | N/A | N/A | *5096 |

| HM 2000 KM 7000 H | N/A | N/A | 6800 |

| HM 2000 KM 9000 H | N/A | N/A | *6800 |

| HM 2500 KM 9000 H | N/A | N/A | 8480 |

Special sizes on request.

Note: The table data are approximate values which must be confirmed by MIXACO.

Mixer sizes for soft PVC Heating Mixer (HM) with horizontal Cooling Mixer (KM)

Parameters

Bulk density: 0.5 kg/Ltr.

Heating temperature: 120 °C | Cooling temperature: 60 °C (*50 °C)

Filling level: 85 %

| Mixer Sizes | Manual Dosage 4 Batches/h (kg/h) | Semi Automatic Dosage 5 Batches/h (kg/h) | Automatic Dosage 7 Batches/h (kg/h) |

|---|---|---|---|

| HM 200 KM 800 H | 340 | 425 | 595 |

| HM 200 KM 1200 H | *340 | *425 | *595 |

| HM 300 KM 1200 H | 508 | 635 | 889 |

| HM 400 KM 1200 H | 680 | 850 | 1190 |

| HM 400 KM 2000 H | *680 | *850 | *1190 |

| HM 500 KM 2000 H | 848 | 1060 | 1484 |

| HM 500 KM 2600 H | *848 | *1060 | *1484 |

| HM 600 KM 2000 H | 1020 | 1275 | 1785 |

| HM 600 KM 2600 H | *1020 | *1275 | *1785 |

| HM 700 KM 2600 H | 1200 | 1500 | 2100 |

| HM 700 KM 3700 H | *1200 | *1500 | *2100 |

| HM 800 KM 2600 H | N/A | 1700 | 2380 |

| HM 800 KM 3700 H | N/A | *1700 | *2380 |

| HM 1000 KM 3700 H | N/A | 2125 | 2975 |

| HM 1000 KM 5000 H | N/A | *2125 | *2975 |

| HM 1200 KM 5000 H | N/A | 2550 | 3570 |

| HM 1500 KM 5000 H | N/A | N/A | 4459 |

| HM 1500 KM 7000 H | N/A | N/A | *4459 |

| HM 2000 KM 7000 H | N/A | N/A | 5950 |

| HM 2000 KM 9000 H | N/A | N/A | *5950 |

| HM 2500 KM 9000 H | N/A | N/A | 7420 |

Special sizes on request.

Note: The table data are approximate values which must be confirmed by MIXACO.

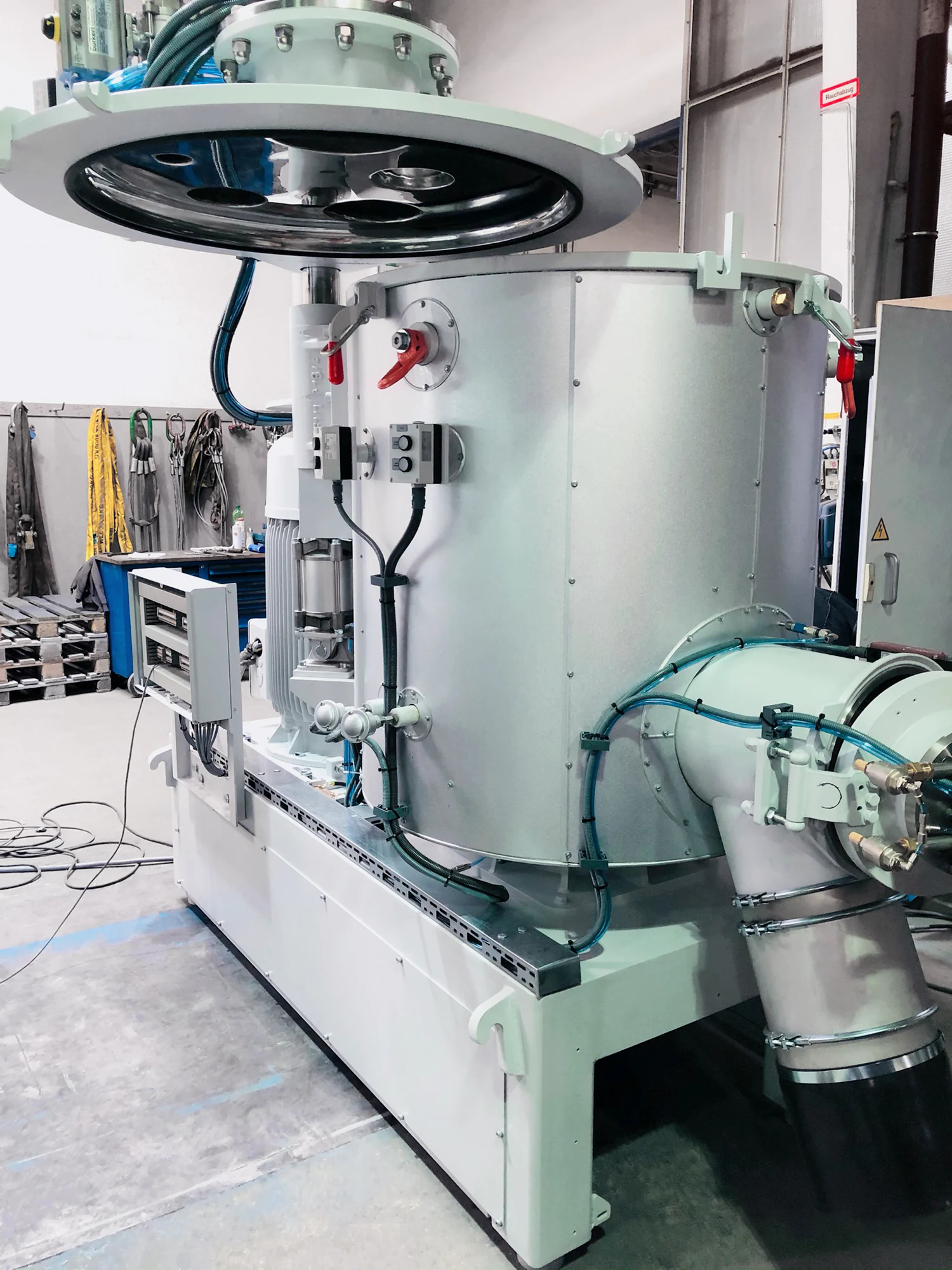

Heating Mixer HM. Mixing up to 1,060 kg per batch.

The new HM series of heating mixers offers the optimal solution for all applications where dispersion of powders with powders or granules with or without liquid addition is required. The possible applications are manifold.

Some main applications:

- Dry blends of rigid and flexible PVC

- WPC (Wood-Plastic-Composites based on PVC/PP/PE with wood flour content)

- Thermoplastic polymers (PVH, PVA, PC, POM etc.)

- Hot or cold dispersion of color masterbatch, additives and powders

- Premixing of powder coatings

- Powder coating/bonding with metallic pigments or mica

Mixer sizes – Heating Mixer (HM)

| Mixer Sizes | Volume | Usable Volume | Capacity kg/batch | Engine Power KW | Boost Engine Power KW |

|---|---|---|---|---|---|

| HM 200 | 200 | 170 | 85 | 45 | 55 |

| HM 300 | 300 | 255 | 127 | 75 | 90 |

| HM 400 | 400 | 340 | 170 | 90 | 110 |

| HM 500 | 500 | 425 | 212 | 110 | 132 |

| HM 600 | 600 | 510 | 255 | 132 | 160 |

| HM 700 | 700 | 595 | 300 | 160 | 200 |

| HM 800 | 800 | 680 | 340 | 200 | 250 |

| HM 1000 | 1000 | 850 | 425 | 200 | 250 |

| HM 1200 | 1200 | 1020 | 510 | 250 | 315 |

| HM 1500 | 1500 | 1275 | 637 | 315 | 400 |

| HM 2000 | 2000 | 1700 | 850 | 500 | 575 |

| HM 2500 | 2500 | 2125 | 1060 | 600 | 700 |

Note: The table data are approximate values that must be confirmed by MIXACO.

Heating/Cooling Mixers for lots of industries.

The MIXACO heating/cooling mixer is the ideal mixer for mixing large throughputs, e.g. PVC (hard and soft), WPC, masterbatches and many more.

Additional features. Maximum Functionality.

Our heating / cooling mixers can be individually extended by additional options and adapted even better to your requirements:

- Hydraulic tool stroke

- Data recording and evaluation

- Remote maintenance

- Cloud monitoring

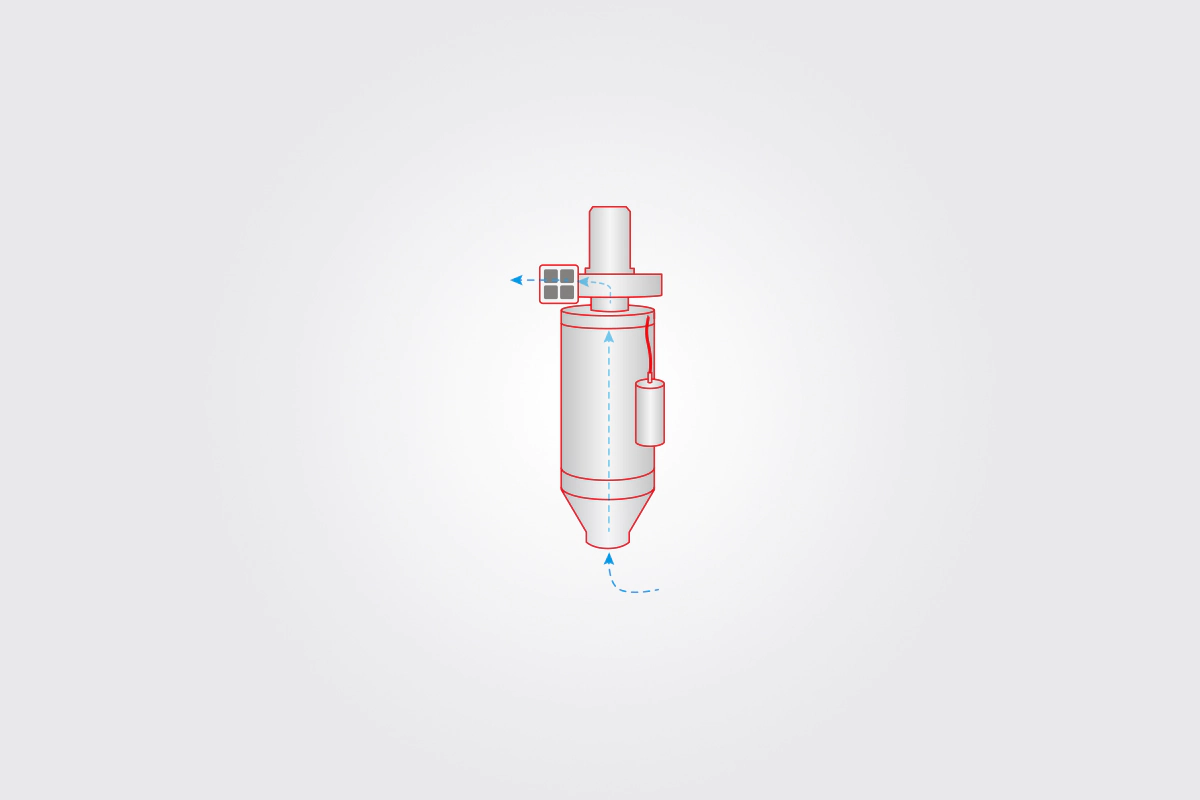

Dehumidification of the mixture by means of aspiration is crucial for the optimum quality of dry blends. A constant air flow transports the moisture out of the heating mixer to prevent buildup in the mixer. Aspiration is optional for the heating mixer and the jet filter for the cooling mixer.

Depending on the design, our mixers can be used in potentially explosive dust and gas atmospheres of all ATEX zones. A machine acceptance test is performed and documented by an official inspection body or a suitably certified employee. The ATEX design can be carried out via nitrogen inerting and oxygen concentration measurement.

As the inventor of the container mixer, we at MIXACO are committed to innovation in industrial mixing technology.

Service & support for our mixers. You can rely on our experienced technicians.

Get quote for the perfect mixer in 2 minutes.

More than mixers. Holistic customer care for over 55 years.

Test mixer free of charge and without obligation

Test our mixers in our test center – with your own raw materials, of course.

Learn More

Mix & Process Consulting

Have your mixing process checked by our mixing professionals – free of charge & no obligation.

Learn More

The MIXACO Technical Center

In our test centers we can optimize all parameters for your compound.

Learn More