MIXACO Infinity Mixer™

The New Standard in Mixing Innovation

With the Infinity Mixer™, MIXACO offers a high-performance High Intensity Mixer designed to meet the highest demands in production and technology. Whether in PVC processing, for battery mixtures, or for masterbatch and compounds, this mixer delivers fast homogenization and consistently high product quality.

Benefits at a glance. Fast and efficient mixing.

By generating targeted distortion and recirculation patterns in a controlled environment, MIXACO´s Infinity Mixer™ delivers exceptional mixing quality—setting a new benchmark for efficiency and performance in industrial mixing.

The result? Faster homogenization, superior batch consistency, short mixing time, high throughput and reduced energy consumption.

- Increased Shear Efficiency – The intermeshing zone applies targeted shear exactly where it’s most effective

- Faster Mixing – Optimized blade design and dynamic flow patterns reduce overall process time

- Faster Cooling – Improved flow dynamics enhance heat exchange, minimizing cooling phases

- Quicker Homogenization – Overlapping flow fields boost mixing kinetics and cut batch times

- Superior Dispersion Quality – Controlled turbulence efficiently deagglomerates particles for consistent results

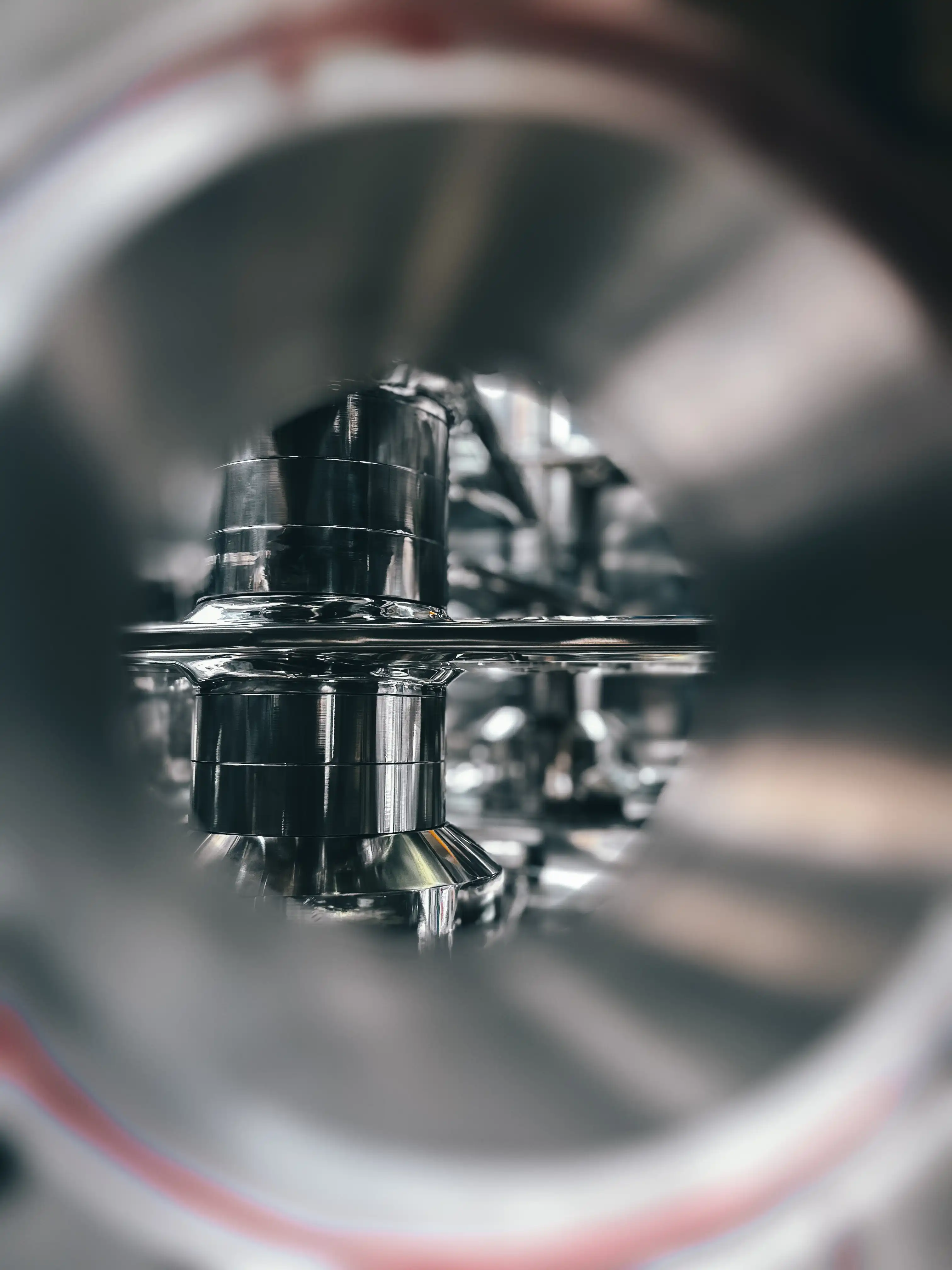

Functionality. Creating more complex friction assemblies.

MIXACO’s new High Intensity Mixer is designed for maximum efficiency and precision. With two operating principles working in harmony, it delivers outstanding performance for a wide range of applications.

Featuring impact tip speeds of up to 60–80 m/s, the mixer ensure rapid and uniform processing, while overlapping mixing tools guarantee consistent results without dead zones.

A higher cooling performance per kilogram of product allows for superior temperature control, preserving material quality and optimizing processing conditions. The result: faster production, greater reliability, and consistently excellent outcomes.

What would you like to mix?

In 2 minutes to your High Intensity Mixer.

Control System. Safe, efficient and economic.

The control of the Infinity Mixer™ is based on a Siemens S7 PLC and meets today’s requirements for safety, efficiency and economy. The development and programming of the control system from a single source ensures optimum integration of the mixer components. Alternatively, it is also possible to use Allen-Bradley components (incl. Panelview operating unit).

The control can also be designed according to UL / NEMA. In addition, the control can be equipped with an interface for data exchange to a higher-level control.

Siemens TP700

Up to 99 mixing programs, each with ten working steps, can be created in tabular form via the TP700 touch control panel. Data acquisition and storage of the measured values takes place. Comprehensive data acquisition on temperature, speed, active power, torque, moisture content and numerous other parameters is possible, which are visualized via the touch panel.

Allen Bradley

Control to UL / NEMA standards with an Allen Bradley PLC and Panelview control panel is also possible.

Working Principle

MIXACO’s new High Intensity Mixer offers two distinct working principles. In the co-rotating mode, both tool packages move in the same clockwise direction. The overlapping flows generate intense particle movement, delivering high shear, rapid mixing, and excellent dispersion. In the intermeshing zone, the combined tip speeds can reach up to 80 m/s, ensuring maximum efficiency and performance.

When operated in counter-rotating mode, the tool packages turn in opposite directions. This principle enables particularly gentle mixing and at the same time supports effective cooling of the mixture. Additional static blade elements installed in the impact area enhance the overall mixing movement, contributing to an even higher degree of homogeneity.

- Homogenizing

- Dispersing

- Agglomeration

- Deagglomeration

- Wetting

- Bonding

- Comminution

- Coloring

- Coating

- Digestion

- Preparation and dyeing of fibers

- Absorbing

- Drying

- Homogenization of bulk materials

- Improvement of product quality

- and much more together with you.

Individual mixing tools for a great variety of materials and products.

The MIXACO Infinity Mixer™ is ideal for a wide range of products such as PVC, WPC, masterbatches, SPC, compounds, pigments, TPE, bonding, additives and many more.

Mixing tools. Optimum mixing quality for your products.

Specially designed mixing tools are available for every container size, enabling optimal vortex formation. The tools can be individually configured, allowing the mixing intensity to be adjusted to your needs and guaranteeing optimal mixing performance.

Benefits of the Mixing Tools

- Proven mixing technology

- Additional heating

- Perfect homogenizing

- Suitable for lots of materials

- PVC, Masterbatch, SPC

- 20-40 m/s

Additional features. From ATEX to chopper.

Container Weighing

Container Tempering

Oxygen Concentration Measurement

Dual Discharge

Jet-Filter

Temperature Sensor

Chopper

Explosion Supression

Injection

Nitrogen Inertization

Wear Protection

Container Charging

Mixer sizes. Other sizes on request.

| Sizes | Usable Volume Liter | Power kW* |

|---|---|---|

| 200 | 170 | 44 |

| 400 | 340 | 90 |

| 600 | 510 | 150 |

| 800 | 680 | 180 |

| 1000 | 850 | 220 |

| 1500 | 1275 | 320 |

| 2000 | 1700 | 400 |

| 2500 | 2125 | 500 |

| 3500 | 2975 | 710 |

| 4500 | 3825 | 800 |

*The power rating depends on the application and may therefore vary.

Technical data

- Impact Tip Speeds up to 60 – 80 m/s

- Container double jacket for insulation / temperature control

- Modular tooling system

As the inventor of the Infinity Mixer™, we at MIXACO are committed to innovation in industrial mixing technology.

Service & support for our mixers. You can rely on our experienced technicians.

Get quote for the perfect mixer in 2 minutes.

More than mixers. Holistic customer care for over 60 years.

Test mixer free of charge and without obligation

Test our mixers in our test center – with your own raw materials, of course.

Learn More

Mix & Process Consulting

Have your mixing process checked by our mixing professionals – free of charge & no obligation.

Learn More

The MIXACO Technical Center

In our test centers we can optimize all parameters for your compound.

Learn More